It is unlikely that anyone will argue that it is much more pleasant to live in a well-ventilated house than in a building where the air stagnates. In addition, regular ventilation has a positive effect on the health of the owners. However, along with this, a problem may arise: often the heat simply leaves the room through ventilation. To fix this, you can always use a device such as an air recuperator. This equipment will provide reliable heating throughout the house and will forget about the problem of heat loss. You can always buy such a mechanism in any specialized store, but to save financial resources it will be much better to make a recuperator with your own hands. It is on this process, as well as on the features of this type of equipment that it is worthwhile to dwell in more detail.

General concept of air recovery

Recovery itself is a mechanism for recovering some of the heat energy. And if we talk directly about air, here we mean the heating of the cold stream entering the room with the help of a removable warm exhaust. Similar designs are very common today. Their full name is the forced-air and exhaust installation, or the forced-air recuperator.

It is important to note one point here: mixing of the incoming and outgoing air does not occur. At the same time, complete recovery will not be possible even with the most modern device (the heating rate varies from 60 to 80%). As a rule, the temperature of 100 ° C is the optimal parameter for warming up the incoming air.

The principle of operation of the recuperator

As mentioned above, this equipment operates due to the exchange of heat flows. In simpler terms, in the cold season, the high temperature inside the room directly affects the air coming from the outside, while in summer this process is the opposite. To implement such procedures, a special device was created, called a recuperator.

The principle of its work is as follows:

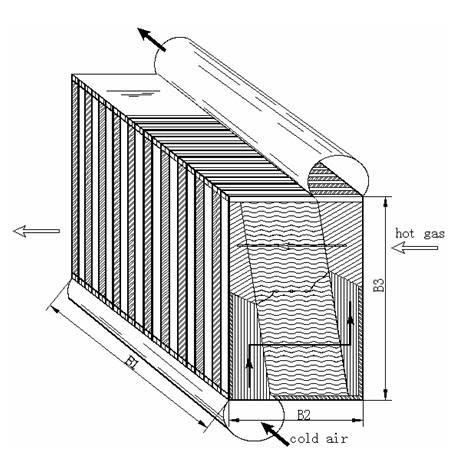

- air from the room moves along a square-section pipe;

- supply flows move in the direction transverse to it;

- mixing of hot and cold air does not occur, since between them there are specially designed for this partitions in the form of plates.

Types of Air Recuperators

In order to properly make a recuperator for a home with your own hands, it is necessary, first of all, to study the types of these devices. The most common of these are the following mechanisms:

- Lamellar recuperator. Based on the name, one can guess that its design consists of special plates, which are combined into a single cube. Encountered streams of air exchange temperature without mixing. This device has compact parameters and is widespread due to its simplicity.

Rotor mechanism. This type of recuperator requires a source of electrical energy. Its cylinder is equipped with a rotor element, rotating without stopping among the channels of intake and removal of air. The dimensions of this device are very large, as a result of which it received its distribution mainly in industrial enterprises. Nevertheless, its efficiency is very high - about 87%.

Equipment operating on the principle of water recirculation. In its technical characteristics, it resembles a plate-type model, however, the device itself is much more complex, the main difference being that some of its structural details can be in different places. Either water or antifreeze acts here as a coolant circulating exclusively by force with the help of electricity.

Roof recuperator. This model is not suitable for residential premises and is used only for industrial purposes. The efficiency is from 55 to 68%, and the arrangement of such mechanisms does not require significant financial costs.

The simplest to operate and connect, as well as the least expensive is a plate heat exchanger, therefore, it will be easiest to make it yourself.

Advantages and disadvantages of a plate heat exchanger

As mentioned earlier, this mechanism will be the best option for your own design. The advantages of a recuperator of this type are usually the following:

- high efficiency (40-65%);

- the absence of any difficulties in the design of the device (the device does not have any moving elements, which significantly extends its service life);

- lack of extra cash costs, since electricity is not needed for its functioning.

However, it is practically impossible to find mechanical equipment that would have absolutely no negative sides. So, from the disadvantages of a plastic recuperator, it is customary to distinguish the following:

- the device is not equipped with a water exchange function, and there is the possibility of only heat transfer;

- equipment is prone to ice on it during the cold season. But this problem is solved: in order to prevent freezing, the device can either be turned off or equipped with a special valve called bypass;

- the design of such a recuperator has crossed pipes;

- to avoid the installation of these elements will fail, and the process itself is quite difficult.

Equipment for the manual manufacture of a plastic recuperator

To independently produce a plastic recuperator for the home, the following materials are required:

- 4 m² of roofing iron treated with zinc, or the same amount of sheet aluminum, textolite, copper, hetinax;

- technical plug having a thickness of 0.2 cm, performing the function of laying between the plates of the recuperator. For these purposes, you can also use a wooden lath impregnated with drying oil;

- ordinary silicone-based sealant;

- tin, metal or plywood box designed for the device body;

- 4 plastic flanges corresponding to the parameters of air pipes;

- differential pressure sensor;

- corner for the device racks;

- insulating material (mineral wool);

- electric jigsaw;

- hardware.

If you have all this equipment, you can start making the recuperator yourself.

Recuperator Creation Process

The action algorithm is as follows:

- The material needs to be decomposed and cut into square plates so that the face size is 20-30 cm. In total, about 70 units of such cassette blanks will need to be made. It is necessary to cut the material with the help of an electric jigsaw so that the plates turn out perfectly even.

- Then you should prepare a cork or wooden slats so that their parameters correspond to the sides of the square. They need to be glued to the opposite sides of each of the blanks except the last. After this, it is important to wait until the glue has completely dried.

- Next, you need to start the process of assembling the squares in the cassette. The recuperator scheme involves laying each of the sheets in relation to the previous one at an angle of 90 °. The last part of the design will be a plate on which nothing has been glued.

- After that, the future recuperator needs to be pulled off with a frame. Here you will need to use the corner.

- It is important to treat all cracks with silicone sealant that does not cause metal corrosion.

- Next, mounts should be made to fix the flanges to the cassette walls. The lower part of the part must be equipped with a special drainage hole, where the condensate discharge pipe must enter.

- On the case walls fixed guides made of corners. You can always get a cassette for any maintenance work.

- The part is mounted inside the case, the parameters of which completely coincide with the diagonal of the square.

- When making a recuperator with your own hands, it is important to remember about laying the insulating material, which in this case is mineral wool. It is necessary to take a layer of this insulation with a thickness of 40 mm and fix it from the inside to the case walls.

- To rid itself of the problem of the occurrence of ice, the design should be equipped with a pressure sensor, which should be installed at the place of passage of warm air.

- The assembly process is completed by installing the finished recuperator in the ventilation system.

As a rule, the efficiency of such self-made mechanisms is approximately 65%, which is quite enough to maintain a favorable microclimate in the living room.

How to calculate the capacity of the recuperator?

Assembling such a device as a recuperator with your own hands, it is very important not only to correctly perform all the activities for its manufacture, but also to correctly calculate the power of this mechanism.

To determine the optimal indicator of the heat energy that circulates between the plates, it is customary to take the following formula as a basis: 20 W * xS * dT. S in this case displays the area of the plate, measured in m².

Calculate the power of the equipment using the following formula:

p (W) = 0.36 * Q (m³ / s) * dT.

All variables are decrypted as follows:

- Q - energy spent on heating or cooling the air flow. This parameter is calculated using the formula 0.335 x L x (t end. - t beginning), where:

- L is the air flow rate, measured in m³ / hour. In accordance with the installation standards, this indicator per person should be 60 m³ / hour;

- t beg is the initial temperature;

- t con - parameter obtained as a result of heat transfer.

- dT is the temperature.

Ways to improve ventilation

In order for the equipment to work comfortably, there are some options for improving its functioning. These measures will certainly increase energy consumption, but efficiency will increase.

To clean the dust particles coming into the recuperator, its channels can be equipped with special filters consisting of aluminum, plastic or fiber. But these elements must be monitored and, if necessary, replaced.

You can avoid freezing of the structure by periodically turning off the supply fan. This will lead to the fact that the plates inside the mechanism will be heated by the outgoing warm air and, as a consequence, thaw.

Compliance with all the above recommendations will allow you to create a high-quality and reliable model of the recuperator, and the manufacturing process itself will not take much time and effort.