Management seeks to develop effective ways to manage production and product quality. There are several approaches to solving this problem. We present the authors of the theory of continuous improvement of the processes of Walter Schuhart and William Deming, whose control cycle is known throughout the world. They suggest that, despite the large difference in production, the algorithm of actions for all systems is the same. Let's talk about the essence of this theory and how to apply this model in practice.

Production management concept

The organization of a process, the impact on different objects is called management. Management processes are found not only in production, each person has to organize his life, make many different decisions, achieve goals. Therefore, management is such a wide area of activity that goes far beyond the scope of creating products or services. The idea of W. Deming, whose management cycle we are considering, is that management exists in almost all areas of human activity, and they have a common procedure. Any management is associated with the collection and processing of information, with decision-making, coordination of processes, forecasting, monitoring and evaluation of effectiveness. Modern management considers many processes, including production, as projects. And an integral attribute of any project is quality. In this connection, there appears such a special area as quality management.

The basic principle of quality management

In any area of production, quality management systems are being introduced in accordance with international standards. They are aimed at ensuring stable quality of manufactured goods or services. Quality management is based on several basic principles. These include orientation to the consumer and his needs, involvement and motivation of employees, making realistic decisions based on facts, leadership of the leader and continuous improvement of quality. It was about the implementation of the last principle that the researchers who created the cycle of Deming and Shekhart pondered. Quality improvement is the permanent goal of every organization. It covers all levels of the enterprise, from individuals to the leader, the production environment and the final product. To improve quality, one of two methods can be used: breakthrough and gradual. It is achieved through the implementation of standardization, analysis and measurement, as well as optimization and rationalization.

Concept of shuharat

The American management consultant, the renowned scientist Walter Schuhart, as far back as 1930, deeply explores the issues of industrial product quality management. His work on control charts, which are a means of fixing observations of the stability and predictability of any processes, has become a serious stage in the development of management. Over the years, he has collected statistics on the control of production processes. And the peak of his scientific work was the Deming-Shekhart management cycle. In his books, he substantiates the statistical method of controlling the stable quality of production processes and final products. In management, Shuhart identifies three main stages: the development of technical specifications and specifications for the production of future products, production in accordance with the specification, checking the quality of the product and its compliance with the specified parameters. Later, the scientist converts this scheme into a 4-step model:

- Product design.

- Product manufacture and laboratory testing.

- Product launch on the market.

- Verification of goods in action, consumer assessment.

W. Shuhart put forward the process method as the most productive in management. His ideas had a huge impact on the development of control theory.

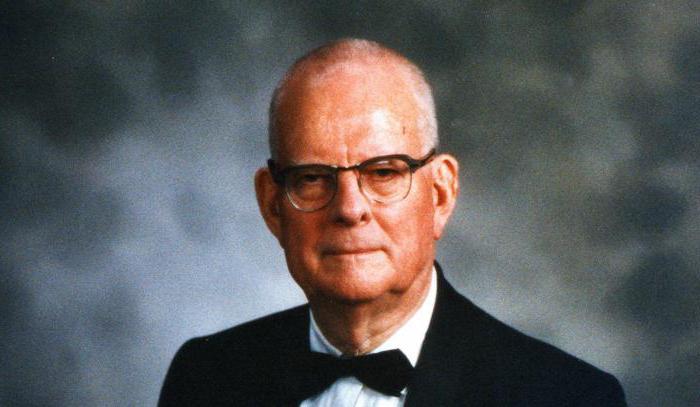

Deming Concept

The student of W. Schuhart, William Edwards Deming, undertook to finalize and improve his theory. He became the creator of the concept and general organizational method of universal quality management. Deming substantiated the view that enterprise quality improvement is associated with the improvement of three areas: production, personnel and products. Also, as a result of many years of research, the Total Quality Management system appeared, which is primarily associated with Deming's developments. The quality improvement cycle, according to the scientist, has no end, but has a circular character. He identified two main mechanisms for improving business: quality assurance (production improvement, staff development , etc.) and quality improvement. According to the scientist, it is not enough to maintain a decent level of quality, you need to constantly strive to increase its level. The updated Deming cycle includes stages of a slightly different nature. These are: planning, implementation, verification and action. Let us dwell on the characteristics of each stage in more detail.

Planning

First of all, the Shekhart-Deming cycle includes such an important stage as product development and production design. According to researchers, entrepreneurs should constantly plan product improvements. And for this, set new goals, evaluate resources, draw up an optimal plan of action, appoint performers and deadlines. At this stage, it is important to find problems and solutions. To discover the reserves for improvement, it is necessary to carefully analyze the situation, the production process, the market. Analytical actions will help identify potential for improvement. Also at this stage, detailed improvement plans are drawn up, and a production strategy is developed. A high-quality plan allows us to foresee force majeure circumstances and lay a solid foundation for business.

Performance

Implementation of the plan is an important part of management. The Deming cycle involves the separation of the implementation phase as a separate stage of quality management. At this stage, Deming recommends that you first begin implementing small-scale plans to prevent large-scale losses in the event of failure. When implementing plans, it is important to strictly follow the developed instructions and specifications. The manager must carefully track the actions at each technological step in order to comply with all requirements. In Deming's concept, this stage is rather a stage of testing, approbation, rather than mass production. Launching in a series no longer requires such close attention of the leader, but the first launches are extremely important. The manager must be 100% convinced that all technologies are respected, because this is precisely what guarantees the quality.

Check

After the launch of mass production, scientists recommend a diagnostic study. Deming's cycle includes a large analytical stage, where it is necessary to evaluate how the process is going, to try to find new potential for improving quality. It is also necessary to assess the perception of the goods or services by the consumer. To do this, conduct testing, focus groups, analysis of customer reviews. Also at this stage, it is necessary to carry out diagnostics of the course of processes, their compliance with technological standards. In addition, an assessment of the work of personnel is carried out, quality control of the work of employees and products is carried out by key performance indicators (KPI). If any deviations from the specified parameters are detected, then a search is carried out for the reasons for this.

Actions

The last stage of the Deming cycle is the elimination of detected violations and shortcomings. At this stage, all possible actions are taken in order to obtain the planned product quality. Documentation and written consolidation of the results in the form of specifications and instructions are also carried out. The Deming cycle, the stages of which are associated with different stages of quality control, involves a circular motion. Therefore, after all the shortcomings and points of a possible loss of quality have been eliminated, you should again return to the first level and begin to look for new opportunities for improvement. The gained experience of the cycle is necessarily used at the next round; it helps to minimize costs and improve product quality.

The main principles of Deming

Deciphering his theory, the scientist formulates a number of postulates, which are called "Principles of Deming." The quality improvement cycle is based on them and comes from them. The most important principles include the following:

- Persistence of goals. Quality improvement, as the dominant goal, should be consistently achieved both within the framework of strategy and tactics.

- The manager is personally responsible for quality.

- Quality control should not be massive; it must be integrated into the production system itself.

- Norms and assignments should be carefully substantiated and realistic.

- It is necessary to encourage the staff’s desire for education, to motivate employees to improve their skills.

- Improving quality should be part of the mission and philosophy of the company, and first of all, managers should become its adherents.

- Employees should be able to be proud of the results of their work.

Subsequently, based on these postulates, the main principles of the international quality system were formulated.

Application of the Shekhart-Deming cycle

The Deming-Shuhart model received the name “PDCA cycle” and is actively used in modern management practice. The Deming cycle, an example of the use of which can be found in organizing the work of almost all large world corporations, is a recognized tool for improving product quality. This concept was most fully and consistently adopted in Japanese management. In this country, Deming was perceived as a national hero, he received several awards, including from the hands of the emperor. Also in Japan, the Deming Prize is established. At the beginning of the 21st century, the concept began to be actively used in Russian management; it is the basis for the development of international and domestic quality standards.