People who have practicality, good taste and do not want to save on their comfort often choose parquet as a floor covering. After all, with proper care, it is very durable and has a beautiful appearance. Moreover, due to the manufacture of 100% natural material, parquet has absolute environmental friendliness.

But the correct installation of parquet requires professionalism, and any person will not succeed in fulfilling it. Everything changed when the production of parquet boards began in the 90s. Now the wood floor has the form of panels that are closed between each other, and can be laid by anyone who knows how to use the tool and will follow the rules of installation. Further in the article we will try to figure out how to properly install a parquet board and what are the nuances when working with this material.

Material Description

Let's start with the correct understanding of the parquet board as one of the types of wooden flooring. In its structure, it represents wooden planks glued together from different tree species, which are perpendicular to one another. This was done with the aim of increasing the strength of the flooring and making it resistant to temperature extremes.

Parquet board usually consists of three layers of wood:

- Polished and coated with several layers of varnish or oil. Usually it has a thickness of 4 mm and is made of fine wood to give the coating aesthetics.

- It is considered basic and has a thickness of up to 9 mm.

- The third (1.5-3 mm) ensures the stability of all planks and, together with the second layer, is made of coniferous species. Recently, plywood is increasingly appearing instead of the third layer to reduce the cost of coating.

Types of parquet board

Before laying a parquet board, you need to make a choice and know its varieties. So, it differs in the upper layer of valuable species of wood, which can count from one to three strips. Hence, the parquet board is single-lane, two-lane and three-lane.

The top layer of a single-cavity parquet board is one-piece and completely consists of one canvas along its entire length. Since it is the most difficult and expensive to make such a layer to the manufacturer, the board has the highest cost.

In a two-lane parquet board, the top layer consists of two strips of the same width, evenly spaced along the entire length. The cost of such a board is inferior to a single-band look.

The cheapest will be a three-lane type of parquet board, the top layer of which also consists of valuable wood, but has three stripes of equal width.

Advantages and disadvantages

The described type of coating was invented in order to create an alternative to parquet. There is no doubt that the parquet board consists exclusively of natural wood with all its advantages. It is sold absolutely ready for installation, since the material supplied for sale is a panel that is equipped with locks for easy installation and does not require additional processing.

The advantages of a parquet board include a lower susceptibility to temperature differences relative to parquet, which often swells in the warm season due to increased humidity, and begins to dry out in winter due to the use of heating facilities and may even crack. The design of the parquet board allows it to bend and withstand deformations in this way.

In terms of cost, a parquet board also outperforms parquet due to the use of a smaller amount of natural material for manufacturing. But the disadvantage is the significantly reduced service life (10-15 years) of this material. It is also noted that parquet cannot replace the feeling of warm wood while walking on the floor.

Foundation preparation

After choosing and purchasing a parquet board, the most important stage of preparation of the base begins, since laying the parquet board is allowed only on a carefully prepared surface. It can be wooden or concrete, laying on logs or plywood is also used. But all the expectations of the delights of a new comfortable floor will be groundless if the rough work is not done to prepare the foundation according to the following rules:

- The base must be perfectly flat and strong. If the surface is strong, but has many minor differences, then self-leveling building dry mixes are used. If the base has significant differences, it is necessary to perform a screed.

- Wood does not tolerate moisture, so the base must be dry and free of microorganisms (mold, fungus).

- Any cracks, rises or peeling is not allowed. Cracks are covered up, delaminations are cleaned and displayed under the ideal level of foundation, lifts are removed and cleaned.

- The surface must be free of dirt and dust.

- Parquet board is laid exclusively on the substrate. Its quality can be foamed polyethylene or pressed cork. In rooms with high humidity (toilet, bathroom, sauna, etc.), a 0.2 mm polyethylene film with an overlap of 20 cm is additionally laid on the base.

- It is recommended to keep the parquet board in the room where it will be laid, for two weeks before laying.

It is also allowed to lay the parquet board on the heated floor, but here there are some nuances.

Laying on a heated concrete floor

Parquet board is able to evenly distribute incoming heat. Because underfloor heating will be a good reason for her. But before laying a parquet board on a warm floor and during further operation it is important to perform several simple tasks:

- It is necessary to turn on the floors at least 2/3 of their rated power at least 2 weeks before the installation, and a couple of days before installation, transfer to the level of 18 ° C.

- When using the floor, it is important not to allow heating above 27 ° C, otherwise the temperature will adversely affect the coating - the floor is dried and the wood can cause additional shrinkage.

- Changes in temperature throughout the day should remain within 5 ° C.

- Wood varieties of beech, maple and so that they react more strongly to moisture and temperature changes, and therefore it is not recommended to lay such parquet board species on a heated heated concrete floor or in damp rooms.

Expansion joint

As already mentioned, due to its naturalness, wood strongly reacts to the level of humidity and ambient temperature. The result is a process of swelling or shrinkage of the material, which must be taken into account during installation in order to prevent floor deformation.

To do this, between the edges of the board and the wall, pipe, door platband, etc., a compensation joint of 7 to 15 mm is left, which will not allow the board to abut against the wall when swelling. In the future, it is easily closed with skirting boards or thresholds.

In order to prevent the appearance of gaps between the baseboard and the board in the winter season (when the floor dries up), when choosing the baseboard, it should be provided that its width is one third greater than the width of the expansion joint. It is also worth making sure that after laying in this seam no cables or other objects that impede the fulfillment of its purpose do not fall.

Laying direction

To determine how best to lay a parquet board, you need to be guided by the direction of the incident light in the room. If the room has an oblong shape, it is better to lay the board longitudinally. When laying on a wooden base, the installation direction is determined by the transverse laying of the parquet board on the floor base boards.

How to lay a parquet board: technology

Laying should start with calculating the number of rows, based on the width of the room. If the width of the last row is less than 4 cm, then the first row should be cut. Since it is possible to correctly lay a parquet board only taking into account the expansion joint, its size should be taken into account when calculating the number of rows. Also, to comply with the expansion joint from the boards of the first row of laying, the ridges that are intended for fastening with other boards should be cut.

Speaking about the laying technology, it is worth noting that its implementation does not require professional knowledge of the builder. Of course, having the experience of such work, installation of the floor from the parquet board can be dealt with much sooner, but the lack of experience will not be an obstacle. So, now we will figure out how to lay a parquet board on our own:

- First, along the walls where the installation is made, wedges are set that will withstand the gap between the boards and the wall. They can be bought or cut in the right size from the same floorboard.

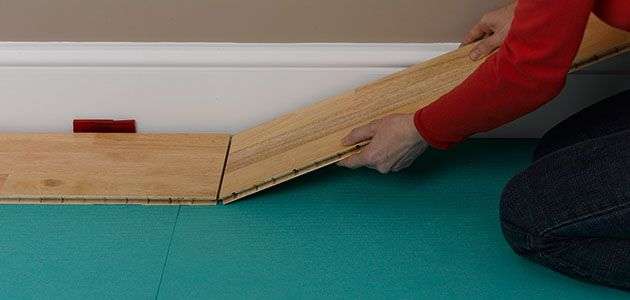

- It is better to start laying from left to right, from a solid wall, putting the first board with a trimmed comb to the wall in the corner. Then they stack the first row, placing the short side of the other board on the first short side of the board. The latter should stand at an angle to the first and rest with its spike in the groove of the first. Gently pressing down, lower the second board, and its spike falls into the groove, forming a lock between the two boards.

- Then in the same way the first row is laid. If the lock is latched with difficulty, slight swaying of the board during lowering is allowed. But you need to do this carefully and without harm to the castle as a whole.

- The last board of the row is cut with a saw or grinder taking into account the expansion joint and fits into the next row.

- Then the second row is formed, and its longitudinal spikes are phased in to the grooves of the first. In places where the locks do not click tightly, it is allowed to hit the board with a rubber hammer. To do this, a small wooden block is placed on the opposite side of the board, and it is gently hammered with a hammer until the lock is completely closed.

- The transverse joints between the boards in both rows should not coincide. It is necessary to ensure that they are at a distance of at least 30 cm from each other. This is the way they are laid to the end of the room.

Methods for laying parquet board

Another significant difference between a parquet board and an array or piece parquet is the variety of ways of laying it. Such opportunities contribute to the wider use of parquet boards as an alternative to parquet flooring. Depending on the base for laying, 3 main methods of how to lay a parquet board are used:

- Floating.

- Glue.

- To the lags.

Floating way

It is immediately worth noting that this method is similar to the method of laying the laminate and is the simplest and most inexpensive. Boards are placed on a special substrate and are not attached to the base. But due to the deformation of the substrate or the imperfection of the base over time, one way or another, deflections of the parquet board will form. It is thanks to them that the board laid by this method cannot be restored without complete dismantling.

In the case of installing a large amount of furniture or other heavy objects, this method of installation is not recommended, as cracks may form between the joints of the boards.

Glue laying method

It is used in cases when a solid floor base is absolutely necessary or when laying in large areas. When using this method, nothing will be better than laying a parquet board on plywood, preferably moisture-proof. To do this, glue is applied to the absolutely flat surface and the plywood is laid in staggered sheets of sheets up to 80 cm. Small gaps of 3 to 6 mm are left between them so that the material “breathes” and there is no deformation due to temperature changes. Next, the plywood is screwed with dowels and screws to the base. Now you can put a parquet board, but only after 2-3 days after the glue has completely dried.

The board is mounted on plywood with polyurethane glue. It is equally simple to lay a parquet board both on glue and on the base without it. This process fits easily into the overall styling technology. The main thing is to prevent the glue from drying out and immediately remove its remnants from the seams.

Lagging

This method makes it possible to quickly and reliably arrange the base for the floorboard. With a flat surface, the logs are mounted on the floor at a distance of 900 mm. If the base is uneven, then bars are screwed into the logs, which are regulated by height bolts.

The base for the parquet board is laid on the logs in order to distribute the load. It can be made of fiberboard, particleboard or special large-sized parquet boards.

There are also options for direct installation of the parquet board on the logs. Further, the process is carried out according to general technology.

How to lay a parquet board on a wooden floor

The complexity of this work lies in the lack of perfect fixing of the wooden floor to the base, as a result of which there are excesses, creaks, gaps, etc. It is possible to deal with this using rough putty mixed with sawdust. With this mixture, all gaps, joints and junctions are clogged. After grinding the base with special equipment.

Plywood is often used to smooth out all irregularities and remove gaps, fixed with self-tapping screws to the floor. The installation of the parquet board is done by glue.

Existing methods of laying parquet boards allow it to be used in almost any conditions, and in appearance it is not inferior to parquet. At the same time, the costs will be significantly less than the cost of flooring, especially if you lay the floorboard yourself.