The decision to make a circular from a small grinder is an excellent option in terms of saving money. To design a sufficiently effective tool does not require the skills of a professional locksmith. You can cope with the task with a serious approach to business with the help of improvised tools and materials. Let's find out how to make a circular from a grinder?

Necessary materials and tools

How to make a circular from a grinder with your own hands? To do this, the following tools will be required:

- actually the Bulgarian herself;

- circular circle;

- sheet metal (tin or galvanized);

- a set of fasteners (bolts, nuts, etc.);

- screwdrivers, pliers, wrenches;

- electric drill with drills for metal;

- metal corners.

Next, we consider the features of the assembly of a manual circular saw from a grinder.

Production of a sliding emphasis

Manual circular grinder requires the creation of a sliding emphasis. As the latter, it is most rational to use several metal corners that will be located on both sides of the saw blade. It is recommended to round off the lower edges of the indicated structural element, which will not allow them to cling to surfaces that will be subject to processing by a home-made circular.

Corners must be bolted together at both ends. To achieve optimal clearance, washers can be placed under the heads of fasteners.

Next, on the case of the grinder, a metal clamp should be fixed, the screed of which should be located below. A metal strip made of tin or galvanized several times folded is threaded here. The ends of the latter are connected to the fasteners located at the ends of the previously assembled sliding stops.

Gearbox preparation

A circular grinder requires a working gearbox. The specified mechanism is removed from the tool, after which the optimal locations for drilling holes in the metal are determined. Such openings will be required to install the axial handle of a homemade circular. Naturally, you can try to hold the tool by the standard side holder of the grinder. However, creating even cuts will become extremely problematic. As practice shows, holding a makeshift tool with a rotating circular disk is beyond the power of even physically trained craftsmen.

Axial handle

To create an axial handle that will allow you to hold a homemade tool in a stable position, it is best to use a metal bar or tube. Holes are drilled at the ends of the workpiece, which will serve to attach the structural element to the grinder reducer. The prepared axial handle is attached using fasteners to the mechanical part of the tool.

Adjusting bar

So that a homemade circular from the grinder allows you to adjust the depth of cut, it is necessary to provide a special bar in the design. A structural element is made of a steel bar with a diameter of about 4-6 mm. One end of the workpiece is bent in the form of a loop, splashed and fixed with the front stop bolts from the corners.

A thread is created on the tail of the bar, which will subsequently enter a special adjustment opening on the handle of the tool. Before installing the rod, one nut is put on its thread. After the tail of the element is threaded into the hole on the handle, a second nut is screwed. Thanks to the tightening and loosening of these fasteners on the thread, the depth of cut is actually adjusted during the operation of a home-made circular.

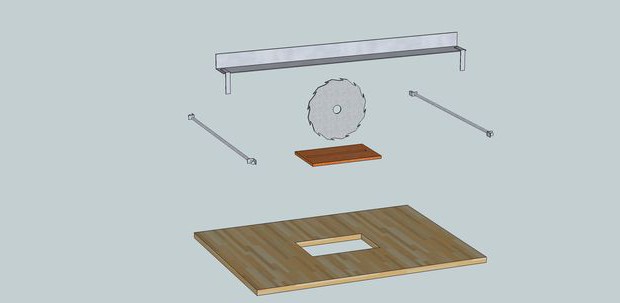

How to make a stationary circular saw from a grinder?

The main difference between the design of hand and stationary tools is the presence of a bed. The work is carried out in the following sequence:

- A special table is prepared, which is coated with a galvanized sheet or tin. To fix the selected material on a plane, just pull it along the edges of the table with metal corners. The basis on which the mechanical part of the tool will be installed must be as stable as possible. Otherwise, swaying will result in inaccurate cutting of materials. In addition, table vibrations can be traumatic.

- According to safety requirements, the circular disk should not protrude a third of its diameter above the table plane. Therefore, to saw a wooden block with a thickness of about 10 cm, you need a cutting wheel with a size of 35 cm.

- The stationary circular from the grinder should be made on the basis of a sufficiently efficient engine. Here it is necessary to use an engine from a grinder with a power of at least 1 kW.

- The basis of the adjustable stop will be a metal corner 7-8 cm long. The indicated element is superimposed on the table and fixed with bolted connections.

- A stationary circular from a grinder involves the creation of a shaft. The latter is recommended to be purchased in finished form, since when it is independently machined, critical errors may occur. Choose a shaft that contains mounts to securely fix the circular disk.

- As a transfer, a V-belt type pass will serve.

If necessary, a circular from a Bulgarian with his own hands can be made on the basis of a more powerful engine extracted from an old washing machine. In general, the choice of the engine here is limited only by the estimated power of the future instrument, which must be obtained at the output.

Safety measures for the operation of homemade circular

Before starting a self-made circular saw, it is worth taking measures that will avoid injuries. If a hand tool is designed, its start button should be located away from the rotating cutting disc. In the case of a stationary saw, the table on which the mechanical part is located must first be screwed to the floor.

When operating such a potentially dangerous device as a home-made circular saw, basic vigilance must be observed. First of all, you should never be in line with a rotating disk. After all, the latter can jump off the shaft during a set of critical revolutions. Also, do not bring your hands too close to it, which should be no closer than 20 cm from the cutting element.

It is recommended to feed wood to the circular disc using wooden blocks. Moving the blanks with your bare hands is fraught with serious injuries if the material suddenly jumps or splits.