A do-it-yourself hanger for clothes can be made without the help of professionals. To do this, it will be enough to prepare all the necessary materials and tools, as well as get acquainted with the technology of the work.

Preparatory stage

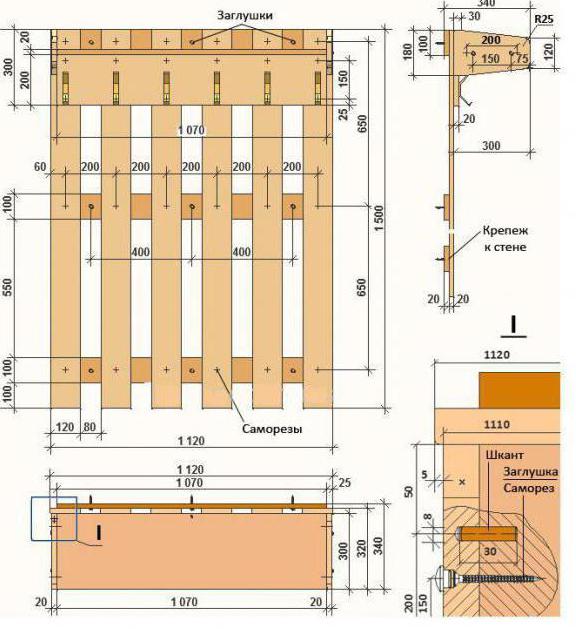

The material that will form the basis of the design will be planed pine boards. You need to choose those that have a thickness within 25 millimeters. In order to complement the shelves of this product, which will be mounted on the wall, you should use a furniture glued board, the width of which is 300 millimeters.

Auxiliary tools and materials

If you will make a clothes hanger with your own hands, you will need to prepare self-tapping screws for wood, PVC glue, acrylic moisture-resistant wood varnish, as well as an electric drill. You will need an electric jigsaw, a hacksaw for wood, a tape measure, a ruler and a square. Wooden clothes hangers are made using abrasive skins, hammers, screwdrivers, circular hand saws, and stains. The latter is necessary if there is a need to change the color of the structure. In order to make the product more aesthetic, you need to stock up with wooden furniture shields, and furniture dowels, the dimensions of which are 10x30 millimeters, will act as fasteners.

Assembly

If you will make a hanger for clothes with your own hands, then after all the tools and materials have been prepared, you can begin to carry out manipulations. All parts must be well-treated with abrasive sandpaper, especially for sharp edges and corners. The first should be rounded. Billets should be removed from chips and burrs, as well as other irregularities that are striking. In the process of work, it will be necessary to observe a certain technology, which involves several stages. When making a clothes hanger with your own hands, then on the table you first need to lay two boards that will be oriented vertically during operation. After they need to place the transverse boards in the amount of 3 pieces. As soon as the right angles are verified, you need to screw in the screws, installing them on the back of the transverse boards. This will connect all the parts together.

In the manufacture of clothes hangers in the hallway, the self-tapping screws must be drowned so that the heads are flush with the surface of the transverse parts. The sharp ends of the screws must not exit through vertical boards. At the next stage, the remaining vertically located boards should be fixed, providing between remove a uniform clearance. Width should be equal to 80 millimeters. It is important to check and, if necessary, adjust the right angles. Now, under the crate, you need to get the holder for the hooks, and then embed two fasteners on each vertically located board. In the manufacture of clothes hangers in the hallway at this stage, the screws should be installed on the back of the transverse parts. This will give the structure additional rigidity.

Shelf assembly

After the master was able to carry out all the above work, you need to dock the shelf with two sidewalls that act as brackets. It is necessary to make sidewalls in advance. Wooden clothes hangers are obtained most quickly if you use an electric jigsaw in the process . With it, you need to cut the blanks along a previously outlined contour, processing them with an abrasive skin. To install dowels, you need to drill holes in all the workpieces. 4 dowels are installed in the shelf, they must first be applied with PVA glue. The sides are connected to the shelves by means of dowels, which are inserted into the prepared holes. On each sidewall you need to embed two fasteners.

Hanger construction assembly procedure

If a clothes hanger will be made, the photo of which you can see in the article, then at the next stage you can assemble the entire structure. Due to the fact that the load from objects on the shelf will affect the sidewalls, they must be fixed to the vertical extreme boards of the crate system as reliably as possible. For this, furniture dowels should also be used with self-tapping screws. At the previous stage, holes were drilled at the ends of the sidewalls. They need to be processed with glue, driving in the dowels in their places. When you will be making a clothes hanger, the photo of which will help you determine the design features, you will need to make holes corresponding to the previous ones in the extreme vertically located boards. It is important to ensure that the pre-assembled shelf is properly docked. Fix this element of the crate with self-tapping screws. Self-tapping screws are installed in the rear sides of the vertical elements - two pieces for each sidewall. After the shelf is fixed to the upper edge of the element on which the hooks are installed. In this case, you can do even with one self-tapping screw.

Conclusion

The drawing of the hanger, presented in the article, will allow you to prepare the elements for the assembly of the structure. Depending on the area of the room, you can adjust the dimensions, taking into account your own preferences and features of the exterior. It is important that the item blends with the decor.