The word spotter came to us from the English language. "Spot" means "target indicator." This unit belongs to a variety of welding machines. It is designed for spot welding and operates on the basis of current resistance. The operation of the device is based on the release of a certain amount of heat energy in the area of contact with the material being welded when electricity is supplied. You can make a spotter from the welding machine with your own hands.

Units are divided into two types: transformer and inventory.

Device purpose

Spotter is intended for car bodywork when alignment of the surface of the part from the inside is not possible. Using this tool, local heating of the metal can be carried out with minor damage to the body part. The welding process itself is as follows: in place of the damaged metal, fasteners are welded to which the spotter is connected, and by means of auxiliary devices or a dent is manually pulled. A DIY body repair tool makes it possible to quickly and efficiently restore a car without painting the area that has undergone deformation.

You can make a spotter from the welding machine with your own hands. During its operation, it is necessary to control the functioning of each part, since there is a high probability of wire breaks and overheating of the unit.

What does the device consist of?

The components of the unit are:

- box;

- cable;

- gun (stadder);

- sharp rod (electrode).

The box contains the entire system of the apparatus for welding.

How to use the device?

For the most clear and fast bodywork of cars, you should adhere to a certain order and process technology, as well as take into account some of the nuances:

- The surface subjected to deformation is initially cleaned of any type of coating (varnish, paint, rust). This work is very important, since the result of the whole process depends on the quality level of the metal compound.

- A ground contact is connected to the surface to be adjusted.

- Fasteners are welded onto the cleaned surface of the damaged area, through which the spotter will be connected.

- Next, the device is captured by the gun, after which the dent is pulled. To level the surface, they resort to the use of a hammer, hydraulic cylinders, stocks and other tools. Taking into account the indicator of the thickness of the metal, it should be determined with the help of which device it is optimal to straighten the car so as not to cause damage to the body. For example, a reverse hammer is not used with aluminum, and not every spotter can handle a galvanized body.

- At the end of body straightening, the welded part is twisted, and the contact point is protected by a grinding machine.

The main component of the spotter

The main part of the unit is a welding gun. For continuous operation, a factory-made device is used. The tool can be made with your own hands on the basis of a gun from building glue or you can resort to using parts from semi-automatic welding. Two identical parts with a thickness index of 12-14 mm are cut from getinax or textolite. In one of them, a bracket is installed, which serves as the fastening of the electrode for welding. If desired, a light bulb and a “Backlight” button and a “Pulse” switch are mounted.

The bracket for attaching the electrode can be made of copper having a rectangular or square cross section. A copper rod with a thickness index of 8-10 mm is used as an electrode for welding. The design of the gun should provide for the possibility of replacing the electrode without disassembling. To connect the gun to the device, a combination of a welding cable with the required cross-sectional index and a five-core control cable with a cross-section of 0.75-1.0 mm² is used. The latter is connected in accordance with the scheme: three wires go to the “Impulse” switch, and two wires go to the backlight and the switch. The welding cable is carefully peeled and sealed into the hole in the bracket designed for this purpose.

How to make a spotter do it yourself?

Many people wonder how to make a spotter from a welding machine yourself . This requires certain skills and understanding of the principles of operation of technology. A DIY spotter from a welding machine, the drawings of which are presented in this article, can be made in the case if you are familiar with the design of the welding machine. Missing parts for the future unit can be purchased. The DIY spotter from the welding machine is mainly made from improvised parts.

Buying a factory device is not always advisable. The cost of a quality unit is quite high. Therefore, you should consider the configuration of the fixture and its drawings, and also figure out how to quickly make a high-quality spotter from the welding machine with your own hands.

The device from the inverter

Many people wonder how to make a spotter from a welding machine with their own hands. It should be noted that an inverter-based unit among homemade products is most often found, although there are many other schemes.

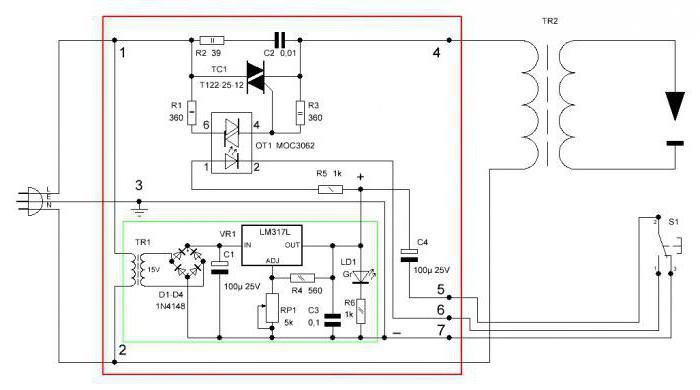

It is not difficult to do a spotter from an inverter welding machine with your own hands . It contains two main components: a welding inverter and a thyristor relay.

To assemble the fixture you will need:

- thyristor with a power indicator of 200 volts;

- 122 volt transformer to control the relay using a button;

- relay with a power of 30 amperes;

- bridge on diodes;

- contact group of 220 volts;

- button for control.

The transformer is connected via a diode bridge to which the thyristor of the electric relay is connected. The transformer feeds the control branch of the thyristor circuit.

Before you make a spotter with your own hands, you need to create safe working conditions. For this purpose, a rubber mat is placed under the feet and adhere to standard safety procedures.

The main stages of assembly

Many people ask how to make a spotter from the Nordika welding machine. This device is ideal for a homemade unit. It is important to be able to change its configuration so that the spotter from the DC welding machine delivers from 1500 Amperes at the output.

The build process consists of the following:

- The secondary layer is removed from the apparatus. Often there are two.

- Then it should be established how many turns are required by 1 V. For this purpose, the primary winding is wrapped with copper wire, and then the volt index is measured. The resulting figure is divided by the number of turns of wire. The result will be an indicator of the required number of turns per volt.

- From the removed secondary layer, a bus must be produced. It is desirable that the cross-sectional index is not less than 160 mm², and the voltage is 6 V.

- If the cross section is much smaller, then you can divide the tire into several parts, which are fastened with a cloth insulating tape. The number of pieces depends on the initial indicator. For example, at a rate of 40 mm², a tire is cut into four parts.

- You will need two tires with a winding of insulation tape or tape for painting. Isolation is done sequentially. First, a layer of insulating tape, then tape, and then an insulating tape is wound over again. Rivets can be placed on open edges.

- The resulting tires are wound on a transformer. This process is not easy and requires certain skills. A hammer and one assistant are required. So the tire will sit better and will not have any damage.

- If the power indicator is sufficient, then the device is ready, if not, then you can conduct an experiment by connecting the wires to the primary winding.

Transformer manufacturing

Making a device like a spotter from a do-it-yourself straightener welding machine involves assembling a transformer. This process is considered the most difficult.

Winding requires a lot of time, but this step is required. The winding can be produced on a w-shaped or ring iron. The wire for the secondary winding must be made of copper or aluminum. The insulation between the skeins must be made of high quality on the basis of varnish or transformer paper in several layers (preferably five or six). For greater reliability, the paper is impregnated with paraffin.

Making a welding gun

The gun for welding can be made from a semiautomatic device. But it requires some additions to attach the instrument to the instrument for straightening. An axis made of brass is fixed inside the semiautomatic device (M10). For the manufacture of ticks, a conventional 20 × 20 mm pipe is suitable.

Which power wire to use?

The power wire that connects the transformer and the gun must have an identical cross section or larger than the bus cross section. It is advised not to use wires that are too long. Their maximum size should be 2.5 m.

The basis of the working cable connecting the gun and the transformer should be a switching wire with thermal insulation. With each heating, this layer will be subject to contraction.

Spotter Design Nuances

The biggest difficulty in adapting the transformer for welding is to increase the output current to 1500 Amps. To this end, experiment with a bus installed instead of the secondary winding. Experience has shown that the cross-sectional index should be at least 160 mm² and the voltage in the busbar should be 6 V.

The most important moment when assembling the transformer is the observance of the correct insulation of the network windings. Incorrect pad can lead to undesirable consequences.