Polyfoam is a heat-insulating material widely used in individual construction. It is sold in canvases, so it is often required to cut the desired length. Anyone who has come across such materials understands that it’s difficult to make it qualitatively ordinary tools. How to cut polystyrene at home? Let's consider further.

What is polystyrene foam?

The full name of the material is polystyrene foam. This type of thermal insulation refers to foamed (cellular) plastic gas-filled masses. If you look at this material, you can see many small balls fastened together. Therefore, during normal cutting, a large amount of small debris is formed, and the cut itself is uneven. How to cut polystyrene foam? The question is interesting and relevant.

Kinds

There are two main options for density:

- Soft . Such formations have a porous structure. When cutting, they crumble a lot, break.

- Solid . This material is easy to process. Minimally crumbles, slices are more even.

It is worth paying attention that the first option is cheaper than the second.

Fields of application

For the most part, this material is used as insulation. Moreover, it is used for external and internal work. With the help of polystyrene, many designers create interesting compositions; it is also used for the production of ceiling tiles, skirting boards, cornices, stucco moldings and other things. This area of application is associated with several main advantages of the material:

- environmental friendliness;

- a light weight;

- low price.

All these areas are directly related to the question: "What is the foam cut?"

Knife

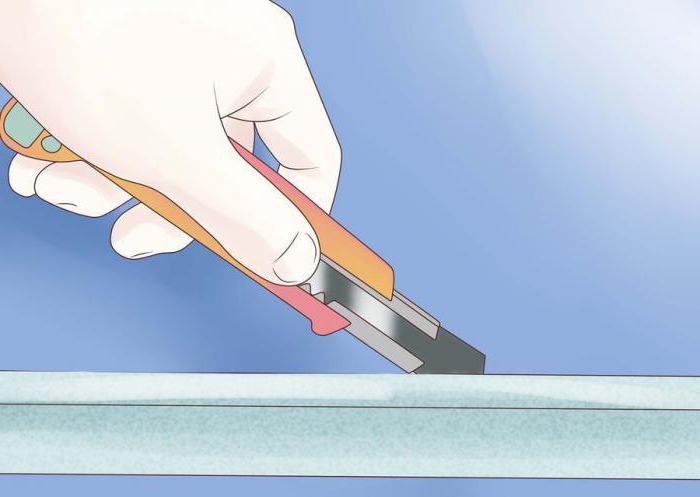

You can take a regular stationery tool. And do the cut. In this case, the process will be accompanied by a creak, a lot of debris, the edges can crumble. This option is suitable for a small amount of trim and thin sheets. In this case, it will often be necessary to replace the blade.

Processing cloths is on a flat hard surface. To make the maximum possible even edges, you should mark the material and attach an even bar to the line, pressing it with your hand. The knife must be driven smoothly, the guide will serve as a stop for the tool. Plus, by clicking on it you can prevent strong debris. This is one of the most common answers to the question of how to cut polystyrene foam.

Hacksaw

This type of tool will allow you to cut sheets of any width, but productivity will be small. Garbage and creaking will also accompany the whole process. The edges will crumble. This method is suitable for a small number of cuts. Work should be done on the table. The cutting part is shifted from the support structure so that a hacksaw can be operated.

Power tool

How to cut polystyrene at home with a power tool?

With large volumes of use of expanded polystyrene, this is an urgent issue. Consider what equipment you can use:

- Jigsaw . It seems that the process is partially automated, the speed of work will increase. But the quality of cuts will be low. There will again be a creak, garbage. It should be understood: plates with a thickness of more than 80 mm are unlikely to be cut with such a tool.

- Bulgarian . Also speeds up the slicing process. But at the same time, the rubbish will scatter in all directions, and even there is a strong noise from the operation of the tool. If you still choose a grinder for cutting, then it is better to buy a diamond wheel with a minimum thickness, this will help to raise the quality of the cut.

We should also consider a tool such as a soldering iron.

Styrofoam Cutting

Often, designers use expanded polystyrene to create any kind of decors.

What is the foam cut at the same time? In such cases, curly cutting of good quality foam is required. The edges should be even, not crumble. For these options, a conventional soldering iron is used. To achieve maximum effect, the tip of the tool is flattened or a nozzle is made of the required size and shape. A heated soldering iron allows you to perform high-quality smooth cutting, which is necessary for decors. Another important point: when working, there will be practically no small rubbish.

Front foam

This material can be produced in several variations:

- pressed;

- suspension unpressed;

- self-extinguishing suspension;

- extruded polystyrene foam.

The thickness of the panels for facade insulation is from 70 to 150 mm. You need to understand that such work is accompanied by a large number of cuts. Therefore, the previously listed methods for cutting foam will not be very relevant.

Knife thermal cutting

For this method, you need to consider heating the tool. Open flames or heating equipment can be used. The knife itself should be well sharpened. It is necessary to stock up on a guide with a straight bar for cutting. It’s best to do the work outside. This will not allow the accumulation of harmful odors that adversely affect health.

Marking of the cut line is done, a guide bar is applied, a cut is made with a heated knife. This method allows you to do this quickly and efficiently.

Nichrome wire

As noted earlier, cutting is best done under the influence of temperature. Facade foam is no exception. The Russian man was always distinguished by his ingenuity, which helped to come up with equipment for manual cutting. Required:

- Desktop;

- a transformer that converts 220V to 12 or 24V;

- nichrome wire;

- adjustable rheostat;

- wires.

Foam cutting wire is fixed across the table with a gap for the required size. Wires, a rheostat, a transformer are connected. When heated, the wire will easily make a quality cut. The material should be fed without much pressure, the temperature of heating the wire is also important. Too high can form inflows.

Designers also use such a tool in their work. The wire allows you to make a number of curly cuts.

Security measures

Why is it better to take a transformer for 12 or 24V for this device. By negligence, you can get an electric shock. With such parameters, it will simply be a burn, while at 220 V the situation can end in disrepair. Another important point: under the influence of heat treatment, polystyrene foam emits harmful substances, therefore it is required to use personal respiratory protection - a respirator. Polyfoam has received a wide scope due to its unique properties. Light weight of the material and at the same time high thermal insulation properties allow it to be used for large-scale insulation of facades, floors, roofs. Such work does not have a significant burden on the foundation, and this is a very important factor that allows you to save on strengthening the foundation. The use in design developments of this material again depends on the ease of the resulting structures, environmental friendliness and the ability to carry out any product.

But in any of this area cutting of material remains important. The time it takes to complete the work and the final result depends on how quickly and efficiently it is performed. Which cutting option to choose is decided individually for each specific case.