Almost any of us was faced with the need to process transparent material, but in reality not everyone knows how to cut glass with a glass cutter correctly. Moreover, this material is quite fragile, and injuries of varying degrees are not excluded when working with it. Of course, you can entrust this business to specialists who will do everything quickly and professionally. But at the same time they will ask for a decent payment for their work, and many of us want to save.

But if in fact, then you can cut the glass of the required size at home or in your own garage. Work, although it can be dangerous, is not very complicated, as it may seem. One has only to know the technology and observe safety precautions.

Safety comes first!

Most owners of apartments or private houses do home repairs on their own, of course, when there is time for this. As with any other business, safety precautions must be taken when working with glass to avoid serious injury. Simple ignorance of how to cut glass with a glass cutter correctly can lead not only to cuts, but also to wounding the eyes with fragments.

Cutting glass on knees or moving objects is highly discouraged, for this you need to use a solid and even surface. Do not grab onto the rough edges, it is better to lift the workpieces from the side edges. To work with glass, you need work clothes made of thick, dense fabric. Shoes should be closed so as not to injure your feet. Having dressed in it before starting work, you also need to take care of the safety of your face and hands. To do this, always wear gloves and safety glasses. At the end of the work, it is necessary to change clothes and change shoes so that the fragments (and they will certainly be on clothes) do not leave the working area.

Glass selection

As experts in glass craft say, the main thing is to choose a good material, otherwise glass cutting will lose its meaning. This is especially important when deciding to replace the window glass yourself.

When choosing glass in a store, if you look at its ends, you can see a bluish or slightly green hue. This indicates high quality material. However, products may be defective. Even if this is a home repair, you should not take glass with scratches. It also happens that during the production of the material the rules are not fully observed, and then various defects appear on the sheets. Characteristic of them are stripes that significantly distort the view.

When choosing glass on the windows, you should choose the optimal thickness, which depends on the dimensions of the frame. For example, its height is no more than 60 cm, then the thickness of the sheet can be from 2 to 2.5 mm. Otherwise (more than 60 cm) you need to select a larger thickness - up to 3.5-4 mm. When cutting glass, a sheet should be formed 3-5 mm smaller than the frame. Otherwise, at the slightest distortion, the glass will not fit into the opening.

Types of glass cutters

For cutting glass, a special tool is used, which everyone knows. It can be of several types:

- roller;

- diamond;

- oil;

- compass.

Roller glass cutters have a round cutting tip. An alloy of cobalt and tungsten is usually used for its manufacture. The number of rollers in one tool can vary from one to six. Unlike other analogues, such an instrument is inexpensive, due to which it received great appreciation.

Diamond glass cutters are used by professionals. Despite the high price, he was, remains and will always be the undisputed leader in the field of glass cutting. It is better for home craftsmen to choose a professional diamond glass cutter, which has a beveled cutting edge, since it will cut more linear meters of almost any thickness. Only need to be stored in a special case. A diamond crystal is used for the cutting tip, and it is known to be the hardest mineral that can be found on Earth. It is worth leaving a small scratch on the glass, as it will crack at the slightest effort. Diamond glass cutters need periodic sharpening by means of a special bar.

Oil tools are similar to roller counterparts, with the only difference being that there is an oil capsule in the handle. It is automatically fed to the roller during operation and to the glass surface. Such a cutter is well suited to solve the issue of how to cut thick glass with a glass cutter.

Using a compass, it is convenient to cut round or oval shapes. It consists of several elements and looks like a well-known school stationery.

Workplace preparation

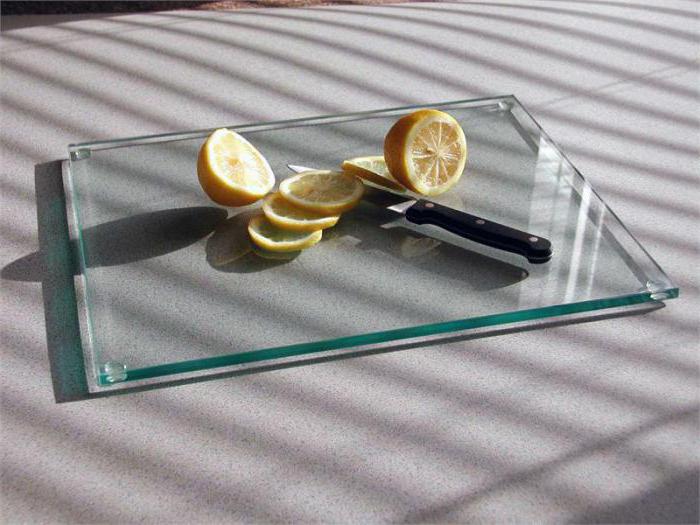

Before proceeding to cutting glass, it is necessary to prepare a workplace. Usually this is given little attention, but in vain. It is important to prepare the material itself for work. If the glass is new, then there is no need to wash it. Otherwise, it may contain small chips, cracks, scratches or plaque. Then you need to rinse the sheet well with detergents, and then dry it by wiping it with paper or newspaper. It is better not to use the fabric, because there are fibers and stains that are useless. Dry glass must be degreased. To do this, you can use rags soaked in kerosene. After this operation, the sheet is dried, but without wiping dry and indoors to avoid dust.

It’s not enough to know how to properly cut glass with a glass cutter, it will not hurt to cut it in order to minimize unnecessary waste of material. A competent drawing drawn up on a piece of paper will make it possible to achieve virtually no waste home production. It will be especially useful if you need to cut out a complex or uneven shape. In this case, it is optimal to position the longest side of the workpiece on the same glass parameter. Sheets need to be cut on a flat surface, excluding slopes. As an impromptu table, plywood or fiberboard is suitable. You can lay an oilcloth or soft cloth on top.

Cutting technology

A clean and dry sheet is placed on the table for cutting glass, and it should be located entirely on the work surface. It is more convenient to first make notes with a marker or a special pencil. For straight lines, you need a ruler, and for complex cutting, you need a pre-harvested pattern. The thickness of the ruler should be at least 7 mm for a snug fit. And so that it does not slip on the glass, you can glue small rubber pieces to it.

A diamond glass cutter should be held, like a pen or pencil, at a slight angle, with little effort. If a thin, colorless line is visible, then everything is done correctly. The roller tool must be held strictly perpendicular to the surface of the glass, holding it with the thumb and middle fingers, and pressing the index finger from above. In contrast to diamond glass cutter, when cutting 3 mm glass, a little more effort is needed here. The trace remains white.

Tool guidance should usually be accompanied by a slight crackle, indicating good performance. Simple rules will help to avoid mistakes:

- The speed of reference should be uniform and not interrupted.

- It is better to drive the glass cutter faster than slower, but not too fast.

- Regardless of the type of instrument, the movement is always directed towards itself, that is, the instrument follows the hand.

- It is not necessary to press the tool strongly on the glass; uniform force must be applied throughout the entire segment.

- Along the line, glass cutters must be carried out only once, no more so that the glass does not crack.

In the absence of experience, it is better to pre-train on some pieces. So you can avoid mistakes, learn to hold the tool and gain experience working with different materials, including corrugated glass.

Correct breaking glass

After an incision, the glass breaks. Thin and small pieces can be broken off with your hands. Larger sheets need to be moved to the edge of the table so that the cut is 3-5 cm from its edge. You need to gently tap the tool handle along the entire line from the back of the glass. Do not forget to hold the hanging part of the sheet. After a while, tapping will give the desired result.

But there is another safer way. Matches are placed under the sheet on one side and at both edges, and then you need to gently and sharply press the glass. The fault should go exactly along the notch line.

In some cases, the cut-off part of the glass is too narrow. For this, the glass cutter has special recesses in the “head”. They need to be inserted into the edge of the detachable strip, for example, 4 mm window glass , after which it should be pulled down with a little effort - the material will break off just by an incision.

Edge processing

After breaking the glass, there is a risk of cutting into sharp edges. Therefore, they need to be "disarmed." At home, this can be done with an ordinary donkey, which is usually used to sharpen kitchen knives. Only previously it should be moistened with water.

An angled oselok having diamond spraying will allow to process both edges at once. A diamond-coated sponge also works well for handicrafts. But if there is a drill, then the process can be accelerated. It is enough to use a grinding nozzle.

Corrugated glass

Corrugated or patterned glasses are sheets on which a relief pattern is periodically repeated. Such material performs various functions:

- is a decorative ornament;

- able to partially scatter light;

- limits pass-through visibility.

At the same time, corrugated glass does not interfere with the penetration of sunlight or artificial light. As for the pattern, it can be on one or both sides. The pattern is obtained by knurling a special roller with some kind of pattern. Mostly widespread corrugated glass received in the field of decoration of doors and furniture. For cutting such sheets, it is better to use a glass cutter. Moreover, the work should be performed on their smooth surface.

Tempered glass

Sometimes some home craftsmen are interested in the question of how to cut red-hot glass. The answer is simple - no way! There is no way to cut or drill it, because when you try to act on it mechanically, it crumbles.

Such material long before the advent of technology "triplex" was used in the automotive industry. In the event of an accident, the glass simply shattered into small fragments, which eliminates the possibility of injury to drivers and passengers. Therefore, in relation to such a material, one should not even wonder about how to properly cut glass with a glass cutter.

How to cut circles?

In this case, it is convenient to use a circular glass cutter, but not everyone has it, and therefore you have to resort to different methods. First you need to determine and mark the center of the circle, and then fix the special suction cup. It is sold at any hardware store and you can find cheap options.

Next, you need to tie a thread to it, and preferably a fishing line, the length according to the desired radius of the circle. The other end is tied to a glass cutter. It remains to pull the fishing line as far as possible and guide the tool. After the incision, it is necessary to make radiation incisions from the circle to the periphery of the glass. If it is necessary, on the contrary, to cut a hole in the glass, then the rays should be carried out inside the outlined circle. And so, as a result, to get equal sectors.

Complex cutting

To cut out a complex arch or different geometric shapes for stained glass using a glass cutter, you need to prepare a tracing paper. But it is better to make a template from plywood or very thick cardboard. Just take into account the allowance for the width of the tool. The template should be firmly held and lead the glass cutter along its edges, preferably without interruption. After the contour is outlined, you need to cut a line perpendicular to the curves at a distance of 7-14 cm from each other. Then you can proceed to tapping. Thin strips break off the grooves of the glass cutter. In conclusion, you must remember to grind off all the edges.