Carrying out all kinds of work on the plot primarily involves the application of a large amount of effort. Only after will it be possible to enjoy the result. Many owners of private territories today are trying to facilitate and mechanize certain operations. For this, cultivators, walk -behind tractors and mini tractors are purchased. However, the most common technique is still a walk-behind tractor, which has a negligible cost. If you use a motor-block of the Neva brand, then you can make a home-made tractor from it yourself . In this case, the assembly of a new device can not be called light, among other things, you will need to buy a special adapter that has a seat. This device will allow you to change the walk-behind tractor. The need is due to the fact that the walk-behind tractor is a structure designed for field work on foot. While the mini-tractor, made on the basis of the walk-behind tractor, is a more comfortable device, since the driver will be able to sit on the seat.

Wizard recommendation

If you decide to make a homemade tractor with your own hands, you should learn some tricks. So, you can purchase other useful devices for the adapter, such as a plow, a cultivator and a harrow. This will make the unit more versatile.

Preparation of necessary materials

In order to make a home-made tractor with your own hands, it is necessary to prepare a walk-behind tractor, wheel bearings, lubricants, hardware for assembly, consumables, a seat of the required dimensions, a wheelset and metal. The latter will be needed for the manufacture of a welded frame. The master will have to prepare a corner, channel and so on. The wheelset must be equipped with a solid axle, however, two axles can be used as an alternative solution. As a fastener, you can use bolts, nuts and studs. Among the consumables, you need to highlight everything that is needed to carry out welding, namely electrodes, gas, wire and oxygen. In order to give the product a final look, you need to prepare a primer and paint.

Tool preparation

If you decide to make a homemade tractor with your own hands, then you should stock up on a certain set of tools, such as a metalworker like keys, a hammer and a chisel, as well as a welding machine that is useful for assembling the frame. If necessary, you need to take care of the availability of a gas cutting kit. Cutting, as well as grinding metal workpieces will allow the angle grinder. Any master in the arsenal has an electric drill with a set of drills, it will also be needed for manipulations. Prepare dies and taps, as well as tools for corrosion protection and painting. For work where the wheelset will be involved, turning equipment may be needed.

Design Features

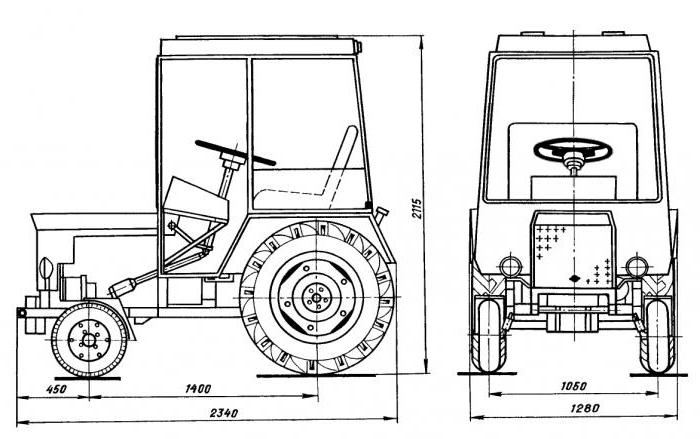

If you decide to make a homemade tracked tractor with your own hands, then you can buy a ready-made module equipped with a seat and wheels. Alternatively, you can assemble all the elements yourself. In the latter case, a simple design without a drive is created. The device will be deprived of a full steering column. The master should remember that additions in the form of a steering column of an all-wheel drive do not give obvious advantages during manipulations, but the assembly process will complicate this. Management of a homemade tractor becomes possible due to the rotation of the transmission-motor unit. To do this, it is recommended to use a standard steering wheel. The walk-behind tractor must be supplemented with a hinged module equipped with a seat, as well as a hitch for earthworks. To implement this simple option, you need to assemble the frame using metal and a pair of wheels. A seat and two trailed units are mounted on it for fixing to the walk-behind tractor. Drawings of homemade tractors you can prepare yourself or borrow from the article. The wheels in this case are not equipped with shock absorbers, since the speed of the device will be negligible.

Technology of work

If you do not have a walk-behind tractor, then you can assemble a home-made tractor from the Zhiguli. The first step is to develop a kinetic scheme that takes into account the equilibrium of the structure. The device will consist of an engine, rear and front axles, a universal joint transmission and a reverse gear. The engine will force the front wheels to spin. Through the chain, the torque will be transmitted to the gearbox, then to the cardan gear and to the rear axle. As a result, the rear wheels will rotate, which act as leading. When a makeshift tractor is made from Lada, a frame will have to be made from corners and pipes. It is important at the same time to correctly position the sleeve and fork, which will ensure the rotation of the trailer. The body is made of metal sheet, the height of the sides should not be more than 30 centimeters. At the next stage, a driver's seat and attachments are installed. After assembly, the unit is important to check for operability. At the final stage, the surface of the metal elements must be primed and painted. Such home-made tractors with a VAZ engine will allow mechanizing the excavation, providing maximum comfort to the driver.

Conclusion

In order to assess the benefits of this machine, which costs impressive money, if we are talking about the factory model, it is necessary to compare some indicators. The cost of maintenance and operation of the mini tractor will cost 4 times cheaper compared to a large analogue. Fuel will need 5 times less. The design is quite simple to manage, and special training for the driver is not required. Even a teenager will be able to manage, so having such equipment in the household is very profitable and convenient.