Installation of the junction box is one of the important points that is necessary when arranging power supply. In addition, it is very important when laying the supply lines from the circuit breaker to the consumer. Installing a separate line for each consumer is too irrational, and therefore, junction boxes or, as they are also called, junction boxes are used.

What is a junction box?

In this case, it can be argued that the installation of the junction box is the installation of an electrical product that has a closed case. The main requirement for the housing is that it must be made of metal or other dielectric material. Naturally, in this case, the second version of the material for installation is much preferable, but provided that it meets the basic fire safety requirements. The housing must be made not only of a dielectric, but at the same time be non-combustible or, as a minimum requirement, not support the combustion process.

After installing the junction box, or rather its case, power and supply wires for consumers or any switching devices are laid inside. The main task of the box case is to ensure the protection of these cables from dust, moisture, dirt and other extraneous things. In addition, it also performs the function of protecting against accidental contact with exposed sections of a working circuit.

Types of Boxes by Material

Today, the most common materials are metal and plastic. Installation of junction boxes facilitates wiring.

As for metal boxes, they are intended for installation in those rooms that are made of combustible materials, such as plastic or wood. Installation of a metal casing is also required if the wall is insulated with combustible building material. Inside these boxes usually lay an extra layer of dielectric to minimize the chance of accidental contact closure.

If we talk about the installation of plastic junction boxes, then they are more common due to the fact that plastic is cheaper than metal. There are two types of plastic boxes. Some products are made entirely from non-combustible materials (for use in high fire hazard conditions), while others can be made from simple raw materials that do not support combustion.

In other words, the installation of junction boxes in drywall, for example, in no case should be the root cause of the fire when the wiring is shorted inside the case.

Inner Boxes

In order to successfully conduct an independent installation, you need to know which boxes exist and where they are best used.

The first type of boxes is intended for indoor installation. As the name implies, they are intended to be installed inside walls or cladding. Usually they consist of two main parts. The first is the box, which must be firmly fixed in the supporting structure, that is, in the wall. The second part is a flat cover with which this object will be closed. The cover itself must remain on the surface and be removable, so that at the right time there is always free access to wires. A distinctive feature of such cases is that they have rather thin walls, since they do not carry any structural load.

If the installation is carried out in a monolithic wall of solid material, it is best to take a round case, since it will be much easier to install. But when mounting in drywall, you can use a box of rectangular shape, as the material is easy to process and you can cut a hole of any shape from it.

Outdoor enclosures

There is an option to install an external leaky housing. As for the conditions of use, it can only be used in cabinets or enclosed spaces. In this case, the casing will be protected from the external environment, as well as power structural elements. For these two reasons, the wall thickness should be larger and the material stronger.

Street products

If the first two types were suitable only for indoor installation, the third option is suitable for those who decide to install the box on the street. Installation of the box in the open air implies exposure to such natural factors as rain, fog, frost, etc. Since all these factors are united by the fact that they create moisture that can conduct electricity, street types of boxes must be airtight. To do this, a special rubber seal is laid between the lid and the body, which prevents water from entering. In this case, the wires are inserted inside using crimp (collet) clamps.

However, it is worth adding here that the estimate for the installation of junction boxes will be more expensive than for the installation of ordinary ones, if the installation is done by specialists.

DIY installation

Since in this case the main goal during installation is to save money, it will be relevant to carry out all the work yourself. To do this, you need to know the installation sequence. Before starting work, it is necessary to conduct a thorough calculation and apply the markup. In addition, there are two ways to distribute the load.

The first is called interior. In this case, an introductory box will be mounted in each room. From the source or base points, a power line will be laid to each box individually. In addition, each line must be wound up on a separate machine. Since in some rooms powerful electrical equipment can be installed, for example boilers, heaters, etc., you will also need to draw a line of separate power outlets.

The second option involves installation on different types of consumers. In other words, there will be one box for lighting rooms, and another for a TV, table lamps and other things, and a third box for connecting power equipment.

After this stage, you can start the rough work: directly to the installation of boxes and laying cables.

Hidden installation

Installation of hidden junction boxes implies their installation directly into the wall. To lay the cable, you need to ditch the walls, and drill a hole for the body, and then fasten it with alabaster. Pre-prepared wires are removed from the box for disconnection. The length of the free ends that remained in the box should be such as to ensure a connection without interference, and there should be a margin of 2-3 alterations (with cutting off the conductors used).

As for the connection method, it does not matter. The only difference is that the boxes for flush mounting have pre-marked holes for cable passage. There is no need to create tightness, since there will be only wall and plaster around, and the alabaster, brought to a creamy consistency, will fill all the cracks, grooves and so on.

Open installation type

In this case, we can say right away that with the open installation of the junction box, the principle of connecting the wiring remains the same as it was with the closed installation method. Only the installation itself will differ.

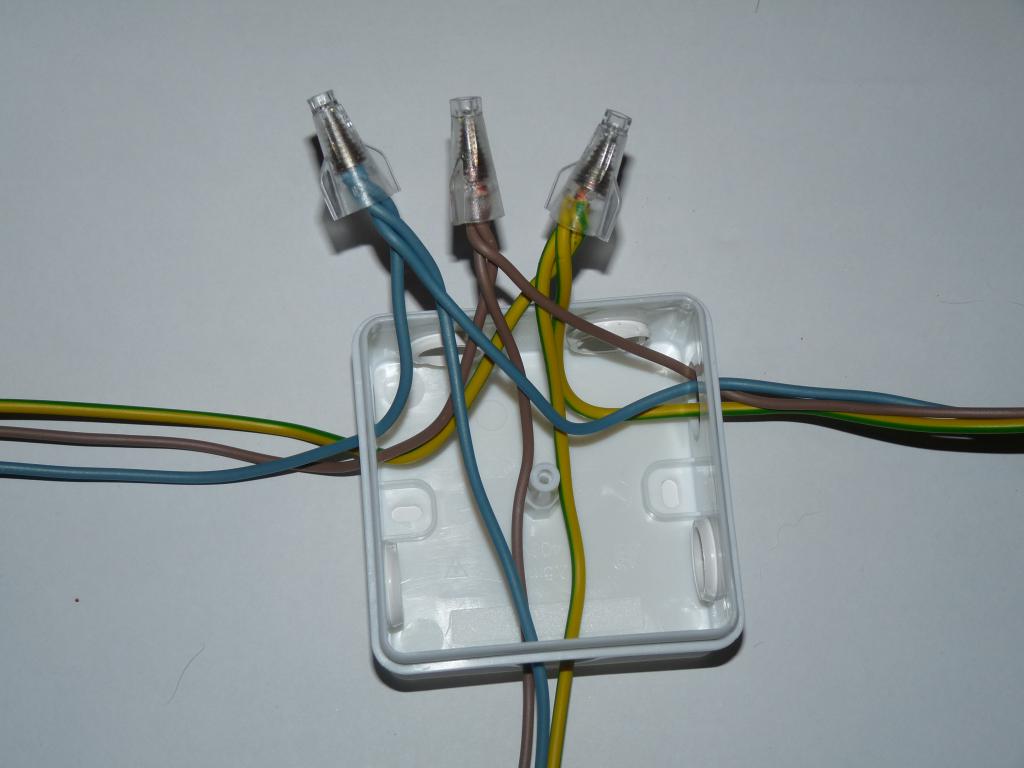

Consider installing an open junction box with flexible cable entry. The first thing to do is to install the junction boxes, and after that you can start supplying external cables to them. Since in this case the housing provides protection from dust, moisture and other things, the wires must be led into it with the help of sealing clamps. It should be added that the wires should be color-coded. If it is a single-phase network, then it is zero, phase and protective earth. A great option would be to hang small tags on the wires to know their purpose. This will help the master not to make a mistake, they are left until all ends are connected to each other. After the full installation is completed, you can transfer the marking to the circuit, and remove the tags from the wires.