The modern tool market represents a wide segment of hot air gun models, which are characterized by a high level of efficiency. These professional devices have many features. But their cost is quite high, so many people collect a hairdryer for soldering microcircuits with their own hands.

Device design

Hot air gun belongs to the category of devices designed for soldering materials subject to easy melting. In addition to its main function, the unit can be used for heat treatment of the surface in order to remove paint or heat the product for bending, for example, pipes.

The design of the device includes:

- case, the distinguishing characteristic of which is a high level of heat resistance;

- a device for forcing air flow;

- element for heating.

The temperature of the hair dryer for soldering microcircuits can increase up to 750 º. To ensure this indicator, the power of the component for heating should be above 1.7 kW. An important function of factory units is the ability to regulate temperature, which rises stepwise.

The temperature needed to solder the materials is controlled by the distance from the nozzle to the material. Most of the modifications are designed in such a way that when the unit is 7 cm away from the surface of the material, the temperature of the air flow is halved.

How is a hair dryer for soldering chips do? The diagram below will help with the assembly of the device.

For what purposes is it used?

Today, such devices are used by masters not only for the purpose of soldering, but also when removing paint, which is especially necessary when working with a surface made of wood. When heated, the coating acquires elasticity and breaks off from the tree. The hot air gun copes well with this function at a temperature of 550 ° C with a distance of 1 cm from the material. Heated air is also used to dry surfaces.

Materials needed to assemble the device

To assemble a hair dryer for soldering microcircuits with your own hands, you should prepare:

- wire;

- soldering iron;

- halogen bulb;

- asbestos;

- heat-resistant adhesive mixture;

- heat-insulating tube;

- screws;

- electrical wire;

- start button;

- rheostat;

- compressor.

Features of self-assembly

Hair dryers for soldering microcircuits, assembled with their own hands, create a hot air stream with a temperature index of at least 850 º. The power indicator of the component for heating should be 2.6 kW. All items should be easy to get and inexpensive.

The design of the unit can be manual and stationary.

It’s much easier to assemble a home-made hairdryer for soldering microcircuits with a stationary modification with your own hands, since its dimensions are not limited, and you do not need to worry about the temperature in the handle area. But in this case, the hair dryer, which is a kind of soldering iron, will be motionless. It is necessary to move the part itself. More options when working gives a handheld device. It should be small and make it possible to hold it with bare hands.

Pen making

The handle should be subjected to maximum insulation. You can often hear that when soldering, you can use a tarpaulin glove. This method is uncomfortable. The handle can be machined with their own hands of their ebonite. This work does not require special skills.

For thermal insulation, it is advisable to use heat-resistant fabric. If you wrap the handle with it, then this will make it possible to work quietly.

The use of tubes of various metals is not recommended. There is an explanation for this. Firstly, such a pen will undergo rapid heating. Secondly, it should be noted that the hair dryer is an electrical device that conducts current. The fewer metal parts, the more secure the use of the unit becomes.

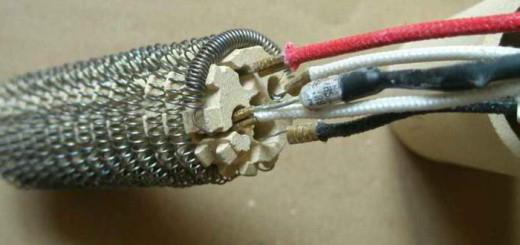

Assembly of the heating element

The main problem when assembling such a device as a hair dryer for soldering microcircuits, with your own hands, is the creation of an element for heating. Heaters from household appliances, such as hair dryers or soldering irons, are unsuitable in this case. The necessary part should be made independently on the basis of their nichrome wire, the cross section of which is 0.4-0.8 mm. Nichrome with a large cross section provides high power, but it will be difficult to achieve the desired temperature. For the compact position of the element for heating, it will be necessary to make a spiral with a diameter of 4-8 mm.

The spiral should be wound on some cylindrical base made of a material with high thermal resistance. In this case, quartz or porcelain in the form of an empty cone or a tube will be used. This base can be removed from the old hair dryer. A quartz product from spotlights of a halogen lamp based on a tube with a power rating of 2.3-2.6 kW becomes more preferred.

As the element responsible for forcing the air flow, a standard small fan is suitable. When assembling a hair dryer at home, this part will become the most expensive. The supercharger can be removed from an old high power hairdryer. Of household fans, the BAKU 8032 brand with a capacity of 30 l / m is suitable.

The assembled hair dryer for soldering microcircuits with your own hands, the photo of which is presented in this article, operates from a 220 V power supply and has a capacity of approximately 420 watts.

The cheapest and unified option is the use of a small compressor for aquarium fish. It is installed together with the receiver (air storage). For this purpose, any bottle made of plastic of small size is used, since in the installation area e there will be no heating, and hot air will exit in the opposite direction.

In the manufacture of the device case, several options are used:

- A material with a high level of thermal insulation (ceramic or porcelain) is used. But these materials are not cheap and will complicate the design.

- Thermal insulation is used with a high degree of reliability for the distribution of hot air. In this case, the material is not affected by temperature, with the exception of the area adjacent to the nozzle.

In the role of the hull base, the handle is also included there, the base of any medium-sized household hairdryer can act. The nose of the body, that is, the nozzle, is made of a heat-insulating material that can withstand a heating temperature of 800 ° C. At the same time, it acts as an insulator of the remaining parts of the body from the action of high temperature. The nozzle should be made of metal, taking into account possible contact with the melts during the soldering process.

Thermal insulation can be provided by quartz elements (tube, plate, mica, fiberglass, glass, porcelain, ceramics, etc.). In the manufacture of the unit will need heat-resistant glue.

The power control system can be assembled from old electrical appliances, provided that they are in working condition. In the role of a switch, a keyboard or button modification is used.

What tools will be needed?

Should be prepared:

- jigsaw;

- vise;

- scissors;

- pliers;

- hacksaw for cutting a metal surface;

- drill;

- a brush;

- a screwdriver;

- calipers;

- soldering iron;

- taps;

- ohmmeter;

- tester.

The main stages of assembly

A homemade hairdryer for soldering microcircuits is assembled in several stages. Work begins with the winding of the spiral of the heating part. The spiral is located on a steel wire with a cross-sectional index of 4-7 mm with tension. It is recommended to wind the spiral with nichrome wire with a cross section of 0.5-0.6 mm. The size of the spiral is selected taking into account the fact that the resistance index will be approximately 75-95 Ohms.

The spiral is wound on a tubular core of a halogen lamp from a searchlight or a soldering iron. The coils of the spiral should be laid equally over the entire area of the base with a small gap. They should not be in contact with each other. An asbestos or fiberglass layer is fixed on top of the laid spiral. The last material is fixed by means of heat-resistant glue. After that, a heat-insulating tube made of ceramics, quartz, porcelain, etc. should be put on the glue layer. The ends of the spiral are brought out. In this case, the ends and output areas are also treated with glue.

The finished heating element is mounted in the internal channel of the hot air gun body. The installation site is covered with plates of quartz, mica or asbestos for additional thermal insulation. The findings of the spiral through a twisted mount are connected to the electrical wire. The electrical wire must have heat-resistant insulation. The wire is routed through a start switch and a rheostat to control the voltage supplied to the coil.

The air blower is mounted flush with the hole of the heating element on the back of the housing. If the compressor or air discharge element does not fit in the housing, then it can be mounted on the outside of the housing end. In this case, a tube is connected to it, which directs the air flow. It leads to a heating element located inside the housing.

Lead wires for power supply connected to the supercharger, connected by a wire for heating so that the switch can control the power supply of both elements. A rheostat for regulating the air flow is introduced into the circuit of the electric wire for discharge.

The electric wire is brought out outside the bottom of the housing handle, and the key or button of the switch and the rheostat levers are fixed in any convenient place on the outside of the base of the product.

Next, half the base are connected and fixed to each other. A tip is made of a heat-insulating material of a conical or cylindrical shape. Then a metal nozzle is attached. The design should include replaceable nozzles with various indicators of the diameter of the hot air outlet.

The basic principles of the unit

A homemade hairdryer for soldering microcircuits works according to the following principle:

- while pressing the start button, the fan and heater start to work; a narrow stream of hot air is directed to the desired point;

- a flux for soldering microcircuits with a hairdryer and solder begins to melt;

- connection parts are heated.

So there is a soldering of details.

Chip soldering

If it is necessary to use a hair dryer as a device for soldering microcircuits, then the temperature of the air flow rises to the level of 700-800 º.

Airflow is guided by a narrow stream. The power of the heating element should be increased to an indicator of 2.3-2.6 kW.

The handle should have a temperature comfortable for the skin of the hands. To solder does not cause inconvenience, the handle can be equipped with an additional protective layer of rubber.

Conclusion

A device such as a hot air gun can be used in many types of work related to soldering microcircuits and small parts. Using the unit, you can solder materials such as linoleum PVC film, dismantle the radio components, dry the joints with glue, melt the ends of the synthetic cords, melt the hot melt, etc. Soldering SMD chips with a hairdryer is of high quality.

The device can be assembled by yourself. In this case, cash costs will be minimal. A hair dryer for soldering microcircuits with your own hands is assembled on the basis of a regular hair dryer. The element for heating is subjected to a larger alteration. The idea of the unit remains the same as a conventional hair dryer. Air is pumped by the fan, passes through the heating element, acquires a temperature sufficient for melting the flux for soldering or desoldering.