Making knives is a very exciting and interesting process. It allows a person to express his creativity and talent in such an ancient craft as blacksmithing or the manufacture of weapons. However, not only the blade itself can be made using various technologies, but also the handle. At the same time, it is worth noting that for many nationalities, one could judge the status of a person and his martial art by the handle of a weapon. Also, making a knife handle with your own hands allows you to adapt a specific weapon to the arm of its owner or to make this tool the most convenient for performing certain tasks.

Currently, there are a huge number of knives that are designed to perform certain functions. Moreover, each of them has its own type of blade and handle. That is why, when you need to make the handle of a knife with your own hands, you should consider its design and purpose.

Fighting blades are usually not decorated with patterns and ornate handles. Their most important purpose is to maintain a certain balance necessary for knife fighting or for throwing. Also, such handles should be comfortable and not restrict movement. Therefore, in most cases, a combat blade is made of metal together with the handle, and after manufacture they can leave it in its original form (throwing knife). Or they use a cord from a certain material to make a handle for knives with their own hands. It is wrapped around a metal handle using special weaving. Such a blade will sit well in the hand, take its shape and make work with such weapons convenient.

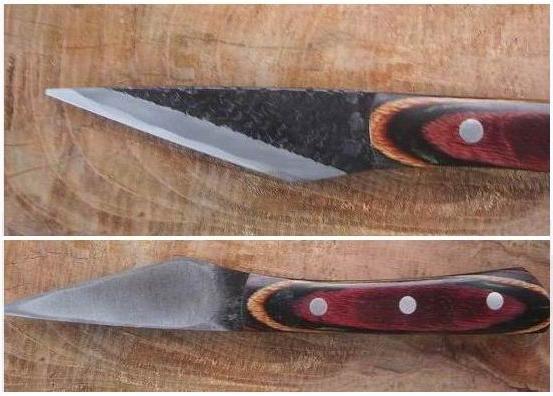

Conventional kitchen appliances do not require special balance and simplicity. Therefore, do-it-yourself knife handles are made of wood or plastic. Usually they are made using pads, which are interconnected through special holes in the metal handle, using rivets. Stuffed pens can also be used. They are pulled with force on a wedge-shaped metal pin, which is attached to the back of the blade.

The most beautiful handles for knives with their own hands are obtained as a result of using the typesetting method. To do this, a threaded pin is welded to the back of the blade. After that, various types of materials are put on him. It can be bronze, textolite, ebonite, plexiglass, leather, bone, copper, or all together in a certain sequence. Then tighten the nut on the thread, thus clamping all the components. Then, such handles for knives with their own hands are processed on an emery machine, giving them the necessary shape, and then polished and ground. The resulting element will not only have a given shape, but also get a stunning appearance thanks to a combination of different materials and colors.

Thus, there are a large number of different methods for making a handle for knives with their own hands. All of them differ in various production technologies, have a specific appearance, and also give the product its properties.