Saw "Partner 350" has a decent power and is very convenient to use. However, the flywheel in this model is not designed for continuous operation. If the motor overheats, various breakdowns can occur. In order to make repairs yourself, you need to know the device of the Partner 350 chainsaw .

Starter problems

Starter quite often fails. In this case, the repair of the Partner 350 chainsaw with your own hands should begin with the following: unscrew the side cover, which is located next to the gearbox. The starter at the saw is located near the engine. In order to inspect this part, the air damper is first removed.

Next, you need to disconnect the carburetor. The starter in this model is connected to the throttle. To separate them, you need to use a screwdriver. If you see carbon deposits on the starter, this part will have to be completely replaced. In this case, the usual modification is installed, and finding it in the store will not be difficult. However, it is best to purchase parts for the Partner 350 chainsaw in specialized workshops. After replacing the starter, it remains only to re-screw the throttle and put the carburetor with a cover.

Flywheel does not work

Flywheels in this saw break quite rarely. Most often this happens precisely because of the engine overheating. In this case, the repair of the Partner 350 chainsaw with your own hands should be started by removing the protective cover. After that, the engine is first inspected. In some cases, the tire may burn out. If there is no darkening on it, then you can immediately twist the flywheel.

In order to make it easier to get it, you must first disconnect the crank. It is located directly above the flywheel. To do this, you will need a Phillips screwdriver. After that, the flywheel can easily be unscrewed from the panel. Particularly carefully you need to inspect its head. If it is deformed, then the flywheel will have to be replaced. In this case, it is necessary to say in the store the exact diameter of the head.

Drum repair

Damage to a ram in a saw is accompanied by a loud sound when turned on. In this case, the repair of the Partner 350 chainsaw with your own hands should begin first of all with an inspection of the fuel system. The problem may be a carburetor breakdown. In some cases, the drum flies out due to the crank that comes out of the grooves. In order to inspect it, you need to open the protective cover. Next, the throttle is removed and the fuel system is checked .

All tubes must be connected. After that, it is necessary to inspect the crank, which is located above the carburetor. If it flew off the grooves, it can be adjusted independently. However, if it is severely deformed, it will have to be replaced. The drum in this saw is located near the air damper. When it hits the clutch, its guard ring is damaged. If it is completely frayed, then the drum will have to be completely replaced. In this case, you need to know the product labeling. The installation of the drum is quite simple, and you can cope with the installation yourself. In this case, it is important not to damage the fuel system during repairs.

Replacing the connecting rod

The crank mechanism is quite complex has a Partner 350 chainsaw. Its failures are often accompanied by loud motor operation. It should also be noted that when the connecting rod mechanism breaks down, the carburetor often goes out of order. In this case, it is more advisable to start the repair of the Partner 350 chainsaw with your own hands by inspecting the ignition module. You will also need to fully check the coupling. In particular, centrifugal clutch deserves attention.

In order to inspect it, it is necessary to remove the top cover. Directly, the coupling of this model is located near the carburetor. To get to the centrifugal clutch in the saw, the flywheel is removed. Next, the carburetor head is disconnected. In this case, it is important not to damage the fuel system. Bolted centrifugal clutch. You can disconnect this part using the key. If cracks are visible under the cylinder, then the clutch will have to be changed. However, some experts advise not to rush this. If the cracks are not deep, you can try to slightly grind the surface with a file.

Clogged breather

The breather in the presented model is clogged when low-quality fuel is used. In such a situation, the repair of the Partner 350 piston chainsaw needs to start with a carburetor inspection. In order to see it, you have to remove the top cover of the device. Then the ignition module is twisted . After that, it is important to disconnect the crank immediately. In this case, you have to use the keys. The next step detaches the drum.

Right behind it is a carburetor. It is not necessary to remove it for inspection. The throttle is checked first. In some cases, the problem may be in it. If the throttle is OK, you need to look at the bus. When it is damaged, its sides are slightly knocked down. Cracks in the center of the tire may also be observed. If the part is deformed, it will have to be replaced. Spare parts for the "Partner 350" chainsaw are best purchased in specialized workshops. It is quite difficult to put the tire on the carburetor independently. In such a situation, it is more advisable to consult a specialist.

Carburetor cleaning

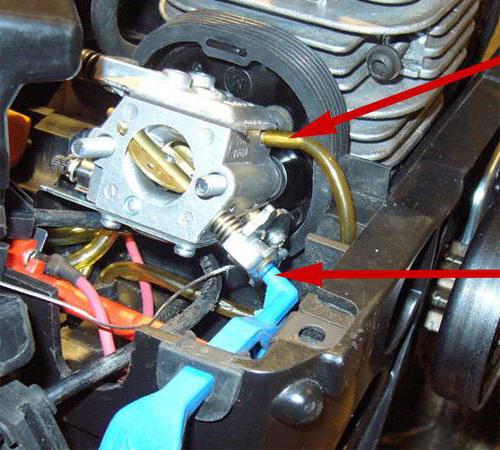

The Partner 350 chainsaw is very demanding on fuel. Carburetor repair is done when its nozzles are dirty. In this case, all internal mechanisms should be examined. When a fuel leak occurs, they should leave a mark on them. If everything is in order with the hoses, you need to inspect the carburetor directly. For this, the cylinder is first removed. Next, it is important to remove the crank, which is located next to the coupling.

After that, it will be possible to look at the carburetor. It consists of a lower unit, as well as an upper part with an ignition system. To unscrew the part, you have to use the keys. After disconnecting the carburetor, you need to inspect its base. If it is not deformed, then the problem lies in the ignition system. In particular, contacts may burn out. Separately, they, unfortunately, are not replaced. In this case, you have to buy a new carburetor. Installing it will be quite simple.

Chain problems

To control the chain, a special catcher is used, which also has a Partner 350 chainsaw. Faults of this type are the result of improper use of the device. As a result, the chain may sag after a while. In such a situation, saw repair should begin with a sprocket inspection. It is located near the handle. To remove it in this case is not necessary. If the teeth of the sprocket are not deformed, you can just try lubricating them with machine oil.

Next, it is important to inspect the trap. In the device, it is quite simple and is a set of clips. When the trap fails, they are knocked out of the chain. It is impossible to correct them independently. The only option is to put a new trap. To do this, use a screwdriver. Its fixing is carried out on three nuts. When installing the catcher, it should be noted that the rollers are located in the upper part and must be near the chain.

Throttle Repair

If the Partner 350 chainsaw does not start, the problem may be with the throttle. In this model, it connects directly to the coupling. When there is a large load on the engine, it does not withstand and bursts. In such a situation, the repair of the saw must begin with an inspection of the coupling. In order to get to it, you will need to unscrew the protective cover of the model. Next, you only have to remove the crank.

After that, it will be possible to inspect the clutch and throttle. In some cases, it flies out of the clamp. In this situation, you do not need to buy anything. However, if a break occurs, a new inductor will be required to repair the saw. In order to install it, it is important to first unscrew the clamp. It is fixed with just one bolt.