Sawdust concrete is one of the varieties of lightweight concrete, which have a low density. Such advantages are attributed to this building material: fire resistance, environmental safety, strength, frost resistance, heat engineering indicators, affordable cost, vapor permeability.

You can make sawdust concrete with your own hands. This will require a specific set of components. The advantage of the materials that make up the sawdust concrete is that they do not need to be prepared in advance. All that is required for this can be purchased at hardware stores or markets. It is quite possible to start harvesting the day before the start of work.

To make sawdust yourself, you need to mix the components. This is a rather time-consuming process, so it is advisable to use a concrete mixer. First you need to pass the dried sawdust through a sieve, its cells should be 10x10 millimeters. Then mix the sawdust with cement and sand. At the next step, lime or clay dough should be added to the mixture, and then again thoroughly knead.

It is necessary to gradually add water to the resulting mixture through a watering can, and the mixture should be mixed after each topping. In the case of the correct preparation of the mixture when it is squeezed in a fist, a plastic lump should form, where dents from fingers will be visible, and there are no drops of water. It is on this basis that the readiness of the composition is determined. Then you can form it into blocks. It is not worth delaying in this matter, since the mixture begins to harden literally after an hour and a half. When laying in the form, it should be carefully tamped, since the presence of air is unacceptable.

If you decide to make sawdust with your own hands, then you should know what sizes the blocks should be. There is a direct dependence on the thickness of the walls, the width of the openings and piers, the method of laying and other factors. It is convenient enough to build a house out of blocks with your own hands, while the width of the walls or the length of the wall section should be a multiple of the size of the blocks. In thickness, they are usually equal to two thicknesses of red brick, taking into account the solution laid between them.

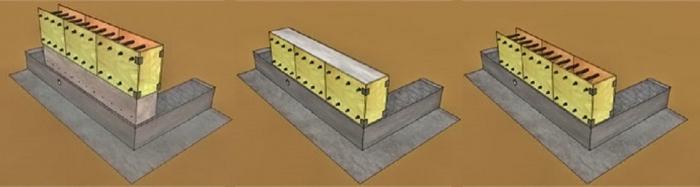

Do-it-yourself sawdust dries long enough, especially if it is molded into large blocks. The acceleration of the process is provided by the holes made, thanks to which its heat-insulating properties are improved. Of these materials, we build with our own hands. When the blocks are cast, the form is not removed from them immediately, but after 3-5 days. To speed up the creation of the required number of blocks, many forms should be made in order to mold building materials continuously. Forms must be detachable, which allows you to assemble and disassemble them as quickly as possible. In the process of drying, shrinkage of the blocks is observed, so the shapes do more in size than necessary. The difference is about ten percent.

As you can see, there are no particular difficulties in the independent production of this building material.