Stainless steel is a special alloy, which, due to its anti-corrosion properties and resistance to aggressive environments, is widely used in the home and industrial sectors. Due to the fact that the composition of the stainless steel is represented by various chemical elements, in production by technological means, having calculated their percentage ratio, it is possible to create the desired type of material. In everyday life, they use taps and faucets, tableware, sinks and kitchen sinks - products made from stainless steel, which is called food among specialists. Very relevant is the question of how to drill food stainless steel. Each master has his own reason why he is forced to resort to this procedure. As experts advise, before you drill a stainless steel, you should carefully prepare. It will not be superfluous to get acquainted with all the recommendations from experienced masters. This is especially important if the procedure is carried out by a home craftsman for the first time. Information on how to drill stainless steel at home can be found in this article.

What are the difficulties of the drilling procedure?

Due to the chemical composition of stainless steel grades , this metal has increased ductility. In the course of work, chip formation occurs, which, adhering to the drills, limits the properties of their cutting edges. As a result, they do not fully function, and a rivet appears in the inside of the hole. Its presence adversely affects the further processing of the metal. In addition, in this place there is a change in the physical properties of steel. Also, during drilling as a result of rotation and cutting, the drill gets very hot. The heat generated on its surface is transferred to the metal. If at this stage no preventive measures are taken, the steel around the hole will turn out to be painted. As a result, the decorative surface will be damaged, and the corrosion resistance of the stainless steel will be reduced. To fix the current situation and restore the initial parameters of steel, the master will have to resort to additional technological operations.

Where to begin?

Very often, beginners who are interested in how to drill a stainless steel correctly do not know where to start. As experienced masters recommend, the first thing you need to do everything to eliminate the above negative factors. To do this, the home craftsman is considering how it will prevent the buildup of chips and how it will cool the metal surface. For those who do not know how to drill stainless steel at home, experts advise using water as a very effective method. However, it is mainly used in a 2 mm stainless steel sheet for the manufacture of a single hole, the diameter of which does not exceed 1 cm. If you need to make several holes, it is more advisable to use oil or a special emulsion for cooling.

Cooling tank

According to experienced craftsmen, water should be used at the very beginning of drilling. To cool a hot drill, dip it into a container of water. It is better to use a small jar, which is convenient to put next to. After immersion of the drill in tool steel, a hardening procedure takes place. If the drill is given the opportunity to simply freeze in the air, then the metal will release, as a result of which it will lose its basic properties. You should also consider how to apply coolant to the drilling site. In production, they use special industrial machines in which its supply is provided. In home workshops, craftsmen have to resort to various tricks on their own, creating a home-made lubrication system. A home craftsman can equip his product with an automobile pump, which will act as a pump. Some handicraftsmen, in order to reduce consumption, surround the contact point of the drill with a stainless steel rubber ring.

Lubricant from engine oil and sulfur

Before drilling a stainless steel, it is necessary to prepare the lubricant and cooling liquid. Judging by numerous reviews, the most common composition is engine oil with sulfur. This solution can be prepared both from colloidal and from sulfur for fumigation. According to experienced masters, special treatment is not required for this substance in the form of a fine powder, it can be immediately added to machine oil. Sulfur is also sold in pieces. The owner will only have to grind it thoroughly.

Soap remover

Judging by the reviews, a good cooling and lubricating agent is a composition based on laundry soap. You can make a tool as follows:

- First, a bar of soap is carefully ground. It is better to get cheap products.

- Next, the soap in the form of a powder is diluted in hot water.

- Then the solution should be charged with technical hydrochloric acid.

- The mixture should stand for some time.

- Dilute with cold water.

- Fatty acids should float to the surface, which will be used for the manufacture of cooling lubricant.

- Sulfur is added to the acid in a ratio of 6: 1.

Judging by the reviews, thick stainless steel is easily drilled with the resulting solution.

What is better to drill a stainless steel?

According to experts, for working with cast iron, stainless steel and other heat-resistant steels, it is better to use special cobalt drills. In their production alloy P6M5K5 is used. Also, in the manufacture of drills for stainless steel, P18 alloy is used. However, in accordance with GOST 10902-77, they are characterized by a limitation of the amount of cobalt to 5%. For those who do not know how to drill with a stainless steel, experienced craftsmen recommend stopping their choice on cobalt products.

The advantage of drills, the chemical composition of which includes cobalt, is that due to the presence of this chemical element, the tool has high hardness. Judging by customer reviews, any stainless steel product is drilled with such a drill without much difficulty. According to experts, the redness index of the product is significantly increased, which means that critical overheating is excluded. Nevertheless, if the power tool is not set to its normal operating mode or if the established standards are ignored and the working session is prolonged, then the drill may overheat. However, even after intensive use, a cobalt product will still have high wear resistance and hardness. Due to the fact that the industry does not produce cobalt drills today, it is quite difficult to find them. Nevertheless, on the shelves of specialized stores there are good analogues, which are also very effective for working with stainless steel. You can use HSS-Co drills. An alloy containing at least 5% cobalt is used for their production. According to experts, foreign drills practically do not differ in composition from domestic cobalt drills. You can also use special drill bits.

About sharpening

Cobalt drills are sharpened on one side. Spiral edges and grooves are provided for the rod in spiral models, with which chips are removed from the hole. According to experts, such drills are considered a universal option for work at home. Provide reliable and high-quality drilling. At enterprises often use step drills. The angle of sharpening can vary between 100-140 degrees. For a stainless steel, it is better to use a drill with an angle of 130 degrees. A product with a reduced rate is suitable for work with duralumin and brass.

About Shanks

Due to the fact that during work, under the influence of vibration, the tool will be subjected to increased mechanical load, the home craftsman will have to decide how to connect the chuck and drill. Experts recommend using a design with a cylindrical hitch. For her, HSS drills manufactured by Inforce are suitable. The tensile strength of these products is 900 N / mm.kv. Despite the fact that the key type design does not provide the best torque, judging by the reviews, it never jams, which positively affects safety. Hex drill bits are also available. Fix them using three-jaw cartridges. The fasteners are quite reliable, but during the change of nozzles the master may have difficulties.

Which tool to use?

Before drilling a stainless steel, you also need to decide which tool will perform the work. At enterprises, special drilling machines are used for this purpose. At home, the amount of work is much less, so the use of machines will be unjustified. It offers a home craftsman - a drill and a puncher. Unlike a drill, a hammer drill is a more powerful unit and therefore more productive. However, it has a massive body and impressive weight. Due to the significant dimensions of this power tool, its maneuverability will significantly decrease.

Mostly perforators are used for work with concrete and brick surfaces. For those who can not decide how to drill a stainless steel, experienced craftsmen advise to opt for a drill. You can use a professional model of a power tool, the power of which is from 1500 watts. Cordless drills rated at 18 V have also worked well. They are suitable for those cases when you need to drill at a considerable distance from the power source.

We drill a stainless steel with our own hands. Step-by-step instruction

For those who are going to work with stainless steel for the first time, experienced craftsmen recommend sticking to the following sequence of actions:

- First you need to prepare a container with lubricant and coolant. What will be this means everyone decides for himself.

- Due to the fact that it is undesirable to work with stainless steel at high speeds, since there is a risk of damage to the cutting edges or break the drill, work should be at low or medium speeds.

- Place the workpiece on a securely fixed surface. It is best to use a metal workbench with a vise on it.

- When the power tool gives the drill the optimum speed, you can make direct mechanical contact with the product. After they begin to carry out the cutting itself.

- At the very end of the work, initial revolutions should be maintained. It is possible to reduce the speed and turn off the device only after the drill is completely removed from the hole.

How to work with a stainless steel sink

Due to the fact that some modern sinks are not equipped with holes for taps or faucets, many beginners ask how to drill a stainless steel sink. There are several ways to cope with this task. Some craftsmen work with a hammer and punch. It is enough to choose the nozzle of the required diameter. There are also special mechanical punches on the shelves that form holes by extrusion. The design of this product is represented by a threaded pin and two nozzles, a tap and a compression washer, the head of which is adapted for wrenches. To make a hole in a stainless steel sink, you need to install a pin on its outside and screw the washer. As a result of tightening it with a wrench, a hole is formed in the product. The third method is considered quite effective.

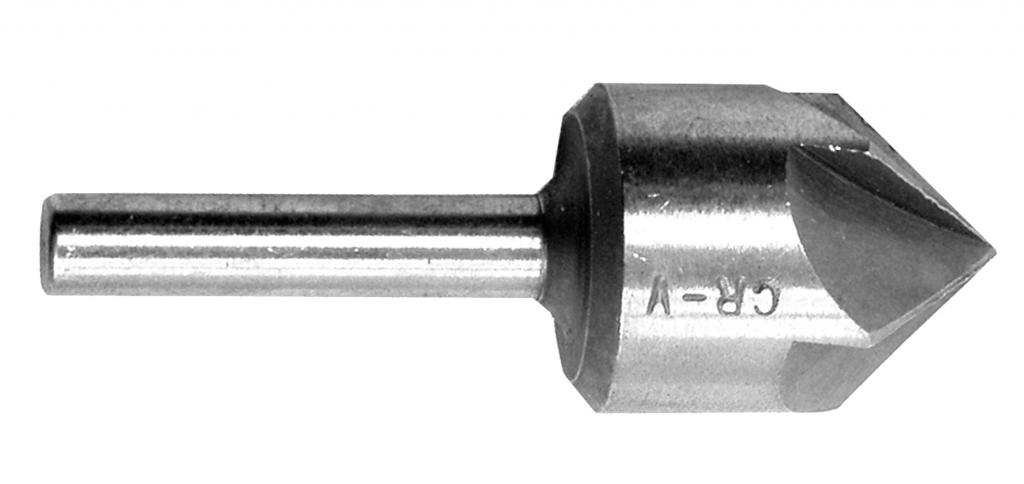

In this case, the master will have to acquire a special drill, which is also called a “carrot” among specialists. The product has a conical shape. The diameter of the cutting edge varies from 6 to 38 mm. Carrot works like an ordinary drill.

Some recommendations from experts

There are situations when you need to drill a 6 mm sheet of stainless steel. Experienced craftsmen advise in this case to use the double method, namely: first, drill a hole with a small diameter, and then expand it. 2 mm products lend themselves well to drills sharpened at an angle of 120 degrees. Within 1 min the power tool should produce no more than 100 revolutions. If the stainless steel is too thin (less than 1 mm), stepped drills should be used.