If you have a welding machine at hand, then not everything can be done, but much. And if you decide to do body repair of cars, then the presence of a large set of tools will come in handy.

In the article we will talk about how to do spot welding with your own hands. This is a device that is useful for repairing car bodies, as well as for other everyday needs. With this tool, you can quickly connect several metal elements.

Principle of operation

Before considering how to do mini spot welding with your own hands, you need to find out how this device generally works. Demand for such products is extremely high: welding will be indispensable when working with metal - such a connection is much more reliable than bolted.

The welding machine works quite simply - due to the energy of electric current, parts from metal are heated. Due to this, a weld is formed. The quality of the final compound depends on the type of material used and its density.

Features of working with welding

Be sure to pay attention to the following points when welding:

- Welding should be done with low voltage. Often, voltages up to 10-12 volts are enough for normal operation of the equipment.

- The process of connecting elements lasts a few seconds.

- The current in the circuit is very high.

- The smaller the area of fusion, the higher the quality of welding.

- It is imperative that the seam withstand high loads.

If you follow all the rules, the end result will please you - the seam will be not only beautiful, but also durable.

It is worth noting that before you do mini-spot welding with your own hands, you should consider several designs. Making even the simplest is quite difficult. It is extremely important in the manufacture of strictly adhering to the instructions - this directly depends on how the device will work in the future.

The simplest designs work by manually changing the pulse duration. In other words, a person who works with welding adjusts the pulse time itself. In more complex designs, a time relay is installed. The duration is set in advance. The operator can only press the electrodes to start the process.

Important design qualities

The main element of the welding machine is a transformer. Homemade products often use devices from microwave ovens, old TVs, etc. First you need to calculate the current necessary for the normal operation of the device. Then, leaving the primary winding on the core (note that this is not always possible - we will explain why later) to completely get rid of the secondary one. It is simply not needed when operating the welding machine.

When winding the secondary winding, a thick copper insulated wire is used. The larger the cross section, the higher will be the current strength in the circuit. Please note that for normal use of the welding machine, you need to use not one, but two transformers from the microwave, connected in parallel. This will increase the output current, therefore, it will be possible to work with thicker metal elements.

Features of the welding circuit

Before you make a spot welding machine with your own hands, it is recommended that you study all the possible schemes in detail. This will answer many questions, and first of all, the following: what metal do you plan to cook with the apparatus? Welders are used both for joining sheet metal and for wiring cables.

Be sure to consider the following points:

- All equipment must be powered by 220 Volt AC.

- At the output of the transformer, the voltage should be up to 12 volts. Usually enough 3-7 V.

- The welding current reaches 1500 Amperes - this is twice as much as the consumption during a short circuit in the car starter.

Be sure to draw up a detailed circuit diagram on which you indicate all the elements: circuit breakers, thyristors and so on.

In the event that dangerous situations may occur during welding, it is necessary to provide for a switch to turn off the device. It is allowed to use non-contact thyristor single-phase switches included in the power supply circuit of the transformer primary winding.

Control schemes

The industry produces MTT4-K systems in which a thyristor switch is installed. It is with its help that the supply voltage is switched. Moreover, the protection unit can operate under voltage up to 800 volts and a current strength of 80 A. The circuit contains such components:

- Power Supply.

- Electromagnetic relay.

- The chain to configure the device.

Together with such a device, you can use transformers whose power does not exceed 20 watts. Please note that the device is installed in the primary power supply circuit. In the secondary voltage is not very high, it can be rectified if necessary using semiconductor diodes.

Transformer Features

Today, one can find the implementation of various functions of control circuits. In the event that it becomes necessary to turn on the device for a certain period of time, it is enough to correctly set the value. And specify it in the system logic settings. In the manufacture of the device, electrolytic capacitors are used, it is desirable to use devices with a voltage margin of up to 50-100 volts.

In the manufacture of the transformer, special attention is paid to its windings. Actually, you need to completely get rid of them and leave only the core.

First, wind the primary winding - for this, use a copper wire in varnish insulation. Be sure to reliably separate the primary winding from the secondary - for this, lay 3-5 layers of varnish. For the manufacture of the primary winding, you need to use a wire 1.5 mm thick - only this one can withstand high current consumption.

The secondary winding is a few turns of thick wire (about 20 mm, maybe even more - it depends on the particular case).

Experts recommend intermediate conclusions when winding the primary winding - this will allow you to get the most out of the device.

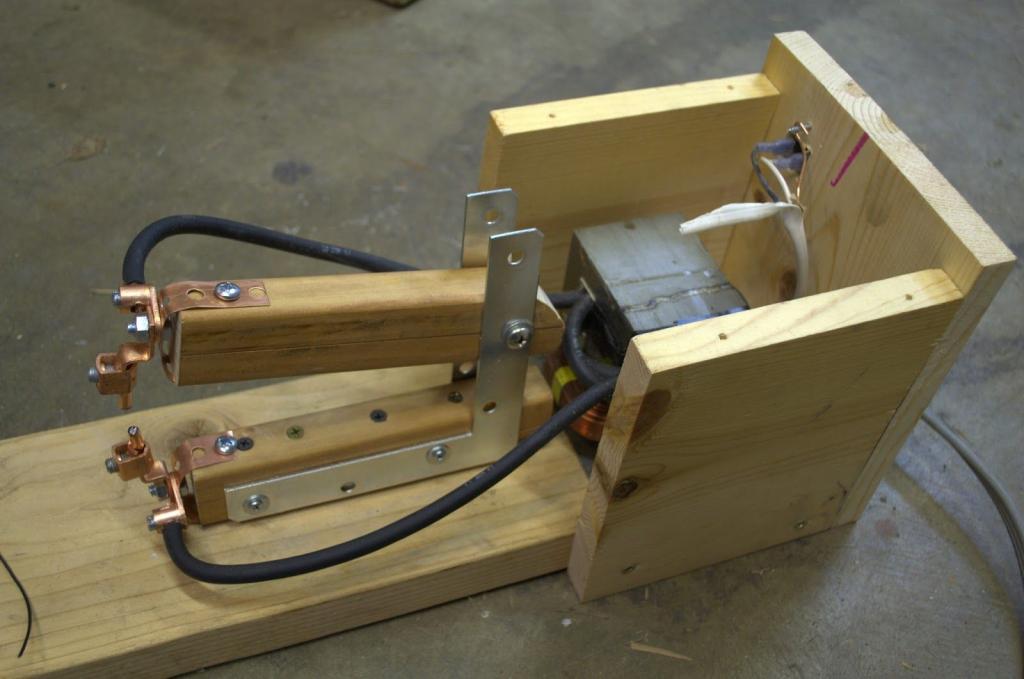

Welding Pliers

Before you do the spot welding yourself, you need to decide what it will be used for. After all, what ticks are directly dependent on this:

- Wearable.

- Stationary

The latter are easy to use, their insulation is reliable and of high quality, but in order to provide a good clamping force, it is necessary to apply force.

As for portable devices, they are convenient to use, and most importantly - they have small dimensions. To control the effort, you just need to change the length of the ticks beyond the apparatus. For the manufacture of ticks, copper rods are used. Please note that the diameter of the electrode must be the same as the secondary wire of the transformer. The electrode cannot be thicker. To improve the quality of the weld, the ends of the electrodes are sharpened.

Microwave transformers

Now, let's look at a short instruction on how to make spot welding with your own hands from a transformer, which can be found in simple microwave ovens. Of course, it will have to be slightly modernized - to completely get rid of the windings. Please note: if you use 2, 3 or 4 identical transformers, then, most likely, you will not have to destroy the primary coils. Such an approach is possible. In fact, if you connect 4 identical windings in parallel, then we can assume (conditionally) that the wire is used for winding it 4 times thicker. In other words, these four transformers will be able to withstand a current consumption of 4 times more than one.

By the way, what kind of microwave to take. Of course, no new one is needed. It is possible that you, acquaintances or neighbors have become unusable. Usually in such devices it is not the transformer that breaks, but the magnetron - a special emitter of microwaves, which, in fact, heat the food. Also, one of the cases can be adapted for the installation of a transformer and all other devices.

A little bit about windings

Now we begin to create a transformer. Suppose you decide not to tempt fate and just make a welder out of 2 transformers. A good solution is that you do not need to deal with the calculation of the primary winding. And this is the most difficult. The data of the secondary winding is much easier to calculate - this can be done even experimentally. To do this, wind several turns (for example, 10) over the primary winding and turn on the transformer in the network. By measuring the voltage at the terminals of the secondary winding, you can calculate how many volts produces one turn.

But this will not be useful to you in the case of the manufacture of a welding transformer - here you need to use a wire of maximum thickness. And how much it will fit in a free place, so much will be. Therefore, the voltage ranges up to 12 V. By the way, to increase the current strength, you can use two transformers connected in parallel. Actually, this is what we plan to do.

Transformer Assembly: Walkthrough

Before doing spot welding with your own hands from the microwave, you need to correctly calculate all the elements. And first of all it concerns the transformer. To do it, perform the following manipulations:

- Using a hacksaw or grinder, cut the core in half - otherwise it will not work out.

- Get rid of the windings.

- You make a framework from dense textolite. The cross-section of the frame should be the same as the core of the transformer. This is the inner clip over which you will wind the wire.

- Winding the primary winding.

- Install the frame and assemble the core. Use a conductive adhesive to connect. Outside it is necessary to pull off the core with metal plates.

- It is recommended to use a wire for the secondary winding, which will fit tightly into the transformer window. This will allow you to get the maximum current. Stack as many turns as you can.

Please note: if you leave the primary winding native, then you do not need to cut the core. Our guide is given only for the most difficult option. Before you can quickly do spot welding yourself, make sure that all the necessary materials are at hand.

Final stage

Perhaps now you know how to do spot welding with your own hands. It cannot be used for the battery (charging it) - the voltage is low. But for the connection of sheet metal, it will be just right. Please note that all connections must be made as reliable as possible. All wires should be the shortest. Moreover, it is important that they are designed to work with the highest possible current.

Before making spot welding with your own hands for a car, you need to think about the design of the pincers. It depends on them how convenient it will be to use the device in the future. And most importantly, a reliable case. It should not be flimsy - keep this in mind. After all, the welding machine can be subjected to heavy loads.