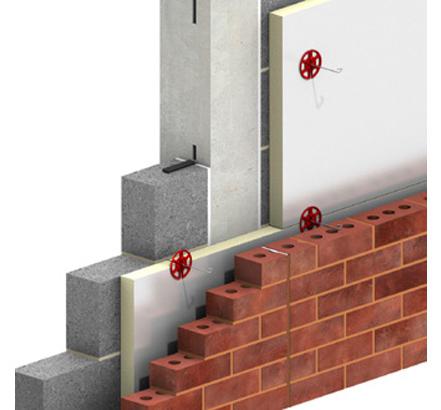

Decorating a house with a facing brick is quite popular. When choosing this material, the existing components of the structure should be linked together qualitatively. They are the supporting wall, insulation and facing material. For this, it is advisable to use flexible connections.

What are these fasteners?

Flexible connections for masonry are a special corrugated core. It is produced with a length of 20 to 60 cm. A flexible connection is designed to provide effective fastening of the facing material to the load-bearing wall through the insulation material. This will create a solid and stable cladding of the building.

The size of flexible communications depends on design decisions. For structures with a height of up to 12 meters, it is recommended to use a product of 4 mm, which is able to withstand a load of about 900 kg. For buildings with a higher height, a bond of 6 mm is required. However, it should not be pulled out of the seam in the presence of a load of about 1100 kg.

Design

Flexible connections for masonry, photos of which can be seen in the article, are rods. They have a circular cross section and thickening at the ends made of other materials. These elements serve as anchors in the process of fixing in the joints of the masonry.

Sand fasteners effectively provide adhesion to the mortar. In addition, additional protection of the wall against corrosion in the alkaline environment of concrete will be achieved. To create an air gap in the layers, it is necessary to use a snap fastener made of plastic.

Features of flexible connections

These products have this name due to their characteristics. The internal walls of the building have a more constant temperature. This is due to the fact that they are not exposed to regular external temperature fluctuations. However, the outer facing wall is subject to reverse effects. This layer is able to heat up to +70 ° C in the summer, and freezes up to -40 ° C in the winter. Significant temperature differences lead to the fact that the inner wall remains motionless, and the outer one changes its geometric size.

It is worth noting that flexible connections for masonry and aerated concrete bend perfectly. Due to this, they are able to maintain the integrity of the structure. Products are not subject to corrosion. They do not break as a result of frequent bends, and also do not create cold bridges with insufficient heat transfer. High strength and durability of flexible ties are more than those indicators that a traditional masonry net has. Consequently, the building as a whole will be more reliable.

Types of products

It is advisable to use flexible connections for masonry and gas block as a connection. However, it is worth choosing the right product. They are divided into two types, depending on the material from which these fasteners are made. The first type are bonds made of composite materials from basalt. An example is the product "Galen" from a domestic manufacturer. The second type includes stainless steel products , which have a high level of corrosion resistance. It is recommended to use BEVER connections from the German manufacturer of the same name.

Structures must withstand the load in order to comply with DIN 1053-1. To do this, it is advisable to use anchors with a bent part, and their length should be more than 25 mm. For this purpose, you can use flexible ties for basalt masonry with a sand anchor with a length of 9 cm. In the case of installation of stainless steel products, it is worth taking ties with a wavy end and a length of 5 cm.

Installation of flexible connections

Using flexible ties for masonry for cladding, the technology should be followed. Their number and location is determined at the first stage of work - in the preparation of design estimates.

Most often, four products should be used for each square meter of the load-bearing wall. If the walls are insulated with mineral wool boards, the pitch of flexible connections should be 50 cm both horizontally and vertically. Also, during the insulation process, polyurethane foam and expanded polystyrene can be used. In this case, the horizontal step of the products is 25 cm, but not less than four pieces per square meter. Vertical should adhere to an indicator not exceeding 100 cm.

It should be noted that flexible ties for masonry should be additionally arranged along the perimeter of the openings. They also need to be equipped in every corner of the building with a step of 30 cm near the parapet and at the expansion joints. During installation, the minimum required penetration depth into the bearing wall and the facing layer, which is 9 cm, is observed.

A situation may occur when the horizontal seams of the outer and inner layers do not match. It is necessary to put ties for the load-bearing wall in a vertical seam using a cement-sand mortar to perform a thorough seal.

Observing the technology for installing flexible connections, you need to ensure that they do not loosen. Initially, a thermal insulation layer is equipped, after which a flexible connection for masonry can be installed. To do this, pierce the insulation plate and mount on it. If the insulation is fastened to an old product, you should wait for the mortar to set in the seams where the bonds are mounted.

Cost

Products of this type have an optimal cost for a wide range of consumers. Flexible bonding for masonry is a budget option, which is able to ensure the reliability of the cladding and the building as a whole, which will lead to significant savings. It is also worth noting that the cost depends on such indicators as quantity, characteristics, manufacturer and manufacturing material. The average price of one product is ten rubles. By purchasing the required number of parts, significant savings will be achieved.