Everyday life quite often forces a person to carry out minor repairs, during which winding is required. It can be a radiator, as well as plumbing. Each home master must learn to apply the tow correctly, as this will come in handy to him sooner or later. Water pipes can be made of metal, plastic, metal-plastic or nylon, each type of material has adapters for connecting other pipes. About such docking and will be discussed below.

For reference

Quite often, home craftsmen have to decide how to wind flax onto a tap's thread. If you want to tightly connect the elements of water supply and pipes, then perform the work called packing. If necessary, pack two pipes at right angles using a sleeve, it is best to cut threads at their ends. The coupling will include internal threads and external turns. Twisting them will not be enough, for proper connection, a thread seal should be carried out.

Description of linen tow

Before flax is wound on a thread, you should familiarize yourself with what flax tow is. It is a fibrous material that is used to seal threads. The product is natural, it is made from the primary processing of thin, uniform and long-fiber flax. The area of use of flax tow is very wide. Depending on the manufacturing technology, the material can be tape, plumbing, jute or construction. In the latter case, we are talking about insulation, which is able to provide reliable tightness of almost any joints. For its manufacture, fully combed fibers are used, which are supplied in bales. Such material is used for construction work on sealing joints, insulation of the log house and laying of wooden elements. It is natural, it is especially appreciated among those who build wooden houses. If the construction tow is delivered in rolls, then it is called tape. This material is also used for caulking sutures in log houses and for laying crowns. As a plus, the use of flax for plumbing works is its cost. The material is much cheaper compared to any other. It is used economically, although the fibers are thin, but they have high strength. If they are wound correctly, they can be used for any kind of work where any joints are used. It can be ceramic and cast iron pipes.

Additional benefits

Before winding flax onto a thread, you should know that it swells, absorbing moisture. This allows you to increase the tightness, because leakage has no paths. The mechanical stability of the material is quite high, it is this characteristic that allows the fitting of plumbing, while the hermetic properties are not lost, the joints can be unscrewed a full turn or half a turn.

Disadvantages of Using Flax

If you are thinking about how to wind flax on a thread, you should first familiarize yourself with all the disadvantages of this material. The substance in the base is organic, so it can rot under the influence of air and moisture. They can get inside during preventive examinations. For this tow additional material is accompanying that is able to prevent decay processes. It can be oil paint, sealing paste, lithol or solid oil.

In some cases, it is necessary to prepare the thread before winding, and if the material is laid too thick, this can cause damage to the joints, which is especially true for brass and bronze. If you are faced with the question of how to wind flax onto a thread, you must remember that the described seal requires the wizard to know the rules for winding. Associated materials in combination with flax can make disassembly much more difficult, this applies to silicone or oil paint. Sometimes such additions make the installation process impossible. Not suitable for using flax, where the temperature can reach 90 ° C. In such places, the material is welded and loses its sealing properties. If you are working with steel, then you must follow the winding technology. Otherwise, the thread may be corroded.

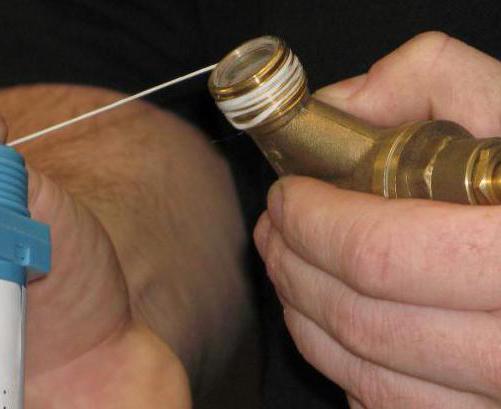

Winding flax onto a new thread

Before winding flax onto the thread, if it is new, then it is necessary to prepare the turns. Many manufacturers today produce fittings that have already been threaded, but the latter have notches that are designed for winding flax. The fact is that on a smooth thread, the material can slip off, it stray into a bundle, which leads to a violation of sealing. In order for the fibers to catch, there should be serrations on the turns. If necessary, you can apply them with a file, a hacksaw for metal or a file. Some craftsmen use a plumbing wrench or pliers: the thread should be clasped, and after a slight pressure to make serifs.

The main thing in this work is to achieve roughness on the turns. Before flax is wound on a thread, it is necessary to separate one strand from a whole pigtail. It is important to capture such a quantity of fibers that the winding is not very thin, but it should not be thick either. Experts advise using a flax thickness that matches two or one match. If lumps are present in the strand, then they must be removed, as well as small villi.

Methodology

You can apply tow by your own technology, some experts twist it into a bundle, someone plaits it in a weak pigtail, and others lay it in the form of a loose thread. The procedure for applying additional material may also be different. In some cases, you can lubricate the thread by wrapping it with fibers, and then apply another layer. Sometimes the fibers are pre-impregnated, and then prepared. Both options are considered correct. If you are thinking about how to wind the flax on the thread - clockwise or counterclockwise - then you can follow the recommendations of experts, some of them wound strands along the thread, others act on the contrary. In this case, the end of the strand should be clamped with a finger outside the turns, the first revolution should form a cross, this will fix the material. Gaps should not be left, you need to lay one turn to another. If you make a connection, then an excess of material will be squeezed out of the fitting, this is true if you are working with an iron pipe and a steel coupling. Brass joints, which is important for those manufactured using modern technologies, burst due to strong pressure.

Specialist recommendations

Around the wound flax, it is necessary to apply sanitary paste or any other sealing material, the movements should be rotational. The work should be as neat as possible. The second end should be glued closer to the edge of the thread, and before twisting it is necessary to check whether the hole in the pipe is filled with sealing material. Now you know how to wind flax on a thread, a photo of these works you can consider in the article. However, from them you will not be able to understand that it is necessary to twist the elements with moderate effort. If the nut goes easily, then a little flax was laid. Winding will be correct if the material does not come out and the surfaces around the joint remain clean. It is not recommended to use an organic tow for gas compounds, this is due to the fact that under the influence of gas, it and silicone, which is used additionally, are destroyed. The use of fum tape is most appropriate here.

Winding flax on ecoplastic products

If you are thinking about how to wind flax onto threads, then you can use the technology that is used in the case of work on products made of ecoplastic. This material, like brass, can burst. The main thing is not to overdo it. Before starting work, both fittings should be connected, count the number of revolutions. Flax is wound evenly, its surface is coated with additional material, only then can fittings be connected. If you idled 5 revolutions, then after winding the tape it is best to make about 4.5 revolutions, while you do not need to reach the end. In this case, it is more advisable to use the packing paste instead of the sealant.

Conclusion

Quite often, home craftsmen are wondering how to wind flax on a pipe thread. In this case, dismantle the connection by inspecting the thread. You need to go through the turns with the tip of a knife or with an awl, this method will allow you to get rid of the accumulated debris. Before brushing the tape with a metal brush, it is necessary to clean the turns until you see a shine.