In many offices, factories, restaurants or other public places, a smoke valve can be found. It is designed to quickly eliminate fires, has increased fire resistance and is installed in exhaust shafts. This article will briefly talk about its design, structure and application. Also, it will not do without mentioning the main malfunctions of the presented device.

DVS valve

The DVS class smoke control valve is used to quickly remove flammable products from the room. Such valves are installed only in smoke mines. In standard condition, the valve flap type (W) is in the lower position and does not allow air to spread throughout the system. If a fire occurs in the room, then the damper, which is located in the center of the hearth, opens, and with the help of the air draft removes all the smoke, thereby preventing fire in other rooms. The fire resistance of smoke valves is up to 180 degrees. This indicator helps to calculate the time at which the valve loses its density. The appearance of the valve depends not only on the place where it will be installed, but also on the conditions for its installation. Such valves can have several types:

- Spring-loaded drive equipped with an electromagnetic base.

- Electromechanical actuators with no spring.

Installation

Installation of the smoke valve is not performed on the air ducts and in rooms that are located in categories “A” and “B” for fire safety. They are also not intended for standard system hoods where various fire hazardous substances are removed.

Smoke fire dampers are only installed in systems where regular cleaning of combustible and grease deposits is used. The installation of this device is carried out only if all the conditions of the "BOS" (safety of construction objects) are met. The fire resistance of the smoke valve web should correspond to the fire resistance of the entire structure on which the installation is carried out. At the initial stage of installation, it is necessary to fix the valve body (preferably with any wooden product). This is necessary in order to prevent distortion of the structure and violation of the initial position of the body, which can lead to slamming of the sash, and as a result, the functionality of the valve will be severely impaired. After the device is fully installed in the fire wall, the spacers can be removed. And only after the valve is grounded and an electric magnet is connected, it is possible to conduct tests.

Design

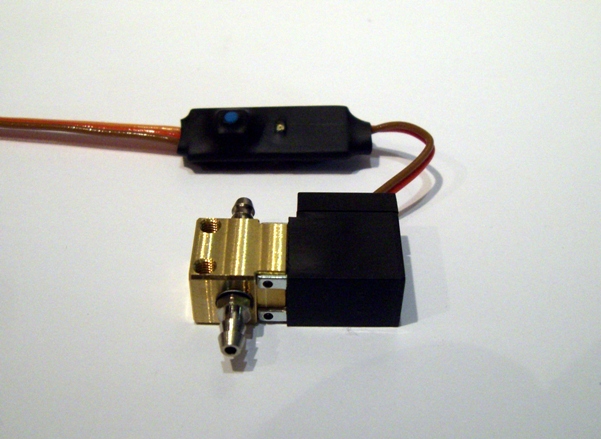

For the manufacture of the body used galvanized steel. To the valve, depending on its type, a wall or channel mechanism is used, which is equipped with two flanges. There are also two types of controls:

- Electromagnetic With this control, the valve goes into open mode only when the voltage interacts with the electromagnet. And only after that the switch throws the circuit and disconnects the electromagnet from the network. The duration of the electromagnet is less than 12 seconds. To set the security mode, you must manually change the position of the plug. For the next unit testing, the valve has a display with a button.

- Belimo electric drive. The dampers in this case work automatically with a constant supply of voltage to the electric drive. When the fire alarm is turned on, the smoke valve drive is completely de-energized and the spring returns the valve to the open position. A special contact group is made for the electric drive, which quickly responds to its position. In addition to automatic control, you can use the manual method, fixing the valve itself in the appropriate position. To do this, stock up on a hex key.

Valve malfunction

Each engine has water-repellent caps. They help seal the joint and guide not only the bushings, but also the smoke valve itself. There are oil seals on this unit. They must tightly hold the rod and hatch of the smoke valve. Over time, the edge is erased and the rubber that wraps around it becomes less elastic. Then smoke may well appear. In this case, it is necessary to replace not only the smoke valve hatch, but also the entire structure that is in it.