What is the essence of water-repellent impregnation? How does this miracle substance work? What types of impregnation exist, for what materials? We will examine in more detail these issues.

Water-repellent impregnation, their action

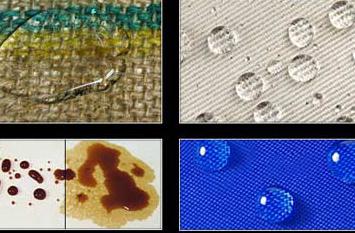

How does water-repellent fabric impregnation work ? Its action is based on enveloping the fibers of the material with a kind of hydrophobic film, which is impervious to water, but allows air to pass through. “Water-repellent” substances do not actually repel water, but are only able to attract water molecules weaker than usual. By tradition, all such impregnations are called water-repellent.

Water-repellent impregnation for clothes or shoes is an emulsion or solution. What happens to the material after processing with such solutions? Initially, the surface of the fabric (or other material) is wetted with water-repellent impregnation, then the solvent itself evaporates, only a very thin layer of water-repellent substance remains, the molecules of which do not evaporate. In this case, fibers are formed that attract water minimally, that is, repel it, and the liquid collects on the surface in the form of separate drops that roll off. Currently, several types of water-repellent impregnations are on sale, water or carbon solvents can be the basis.

The use of impregnation in construction

Very often in construction, water-repellent impregnation is used for concrete, wood, brick. It allows you to protect the material from the damaging effects of moisture. Often mortar joints that are not treated with water-repellents allow moisture to pass in, while heat, on the contrary, comes out. As a result of this process, salt deposits are formed. To prevent this unpleasant process will help a special water-repellent impregnation for concrete.

How to avoid problems in the construction of brick walls

Brick is a porous material; cement-sand mortar is used for its laying. “Natural pressure” causes efflorescence on the masonry (salt formation). To avoid this unpleasant phenomenon, it is necessary to use special means. Water-repellent impregnation for bricks will prevent possible losses and get rid of many problems. Here are just a few of them:

- Freezing of a brick wall during the period of frost.

- Loss of heat, excessive heating costs.

- Blotting of masonry joints in the autumn, the conversion of moisture in the winter into an ice crust.

- The formation of salt stains (efflorescence).

- All of the above leads to the complete destruction of the masonry.

To protect brick walls, there are several types of water-repellent protective impregnations, all of them help to solve not only aesthetic problems, but also prevent the destruction of masonry.

The main types of impregnation for bricks

All protective impregnations, penetrating to a depth of 10 mm, create a water-repellent layer on the surface, provide reliable vapor barrier.

- Acrylic-silicone or acrylic impregnation.

- Two-component silicone water-based impregnation.

- Impregnation varnish - not only protects, but also gives a surface gloss.

- Water-repellent liquid with high protective properties.

Water-repellent impregnation for fabrics and shoes

Weather always dictates us its own rules. Even on a sunny spring day, very often you have to force huge puddles, streams running along the streets of the city. What can we say that, having forgotten the umbrella, we fall under the rain, the outerwear gets wet, becomes unusable if water-repellent impregnation for the fabric was not used in time to protect it. In order to avoid such unpleasant cases, it is simply necessary to use modern protective impregnation. Today they are produced in the form of various aerosols: special or universal. Such products fully protect products from snow, salt, moisture, while not violating the structure of the material, preserve the elasticity of the fabric and its breathability. Colorless water-repellent impregnation for shoes allows you to use it for any colored surfaces that need protection from water.

Universal water-repellent impregnation

Description: the product is used as a water-repellent impregnation for clothes, shoes, any fabric products (umbrellas, tents), as well as nubuck, suede, smooth skin. It is based on fluorocarbon resins, which 100% protect products from dirt, dust, moisture and salt stains. At the same time, air tightness and elasticity of the material are maintained. Such impregnation is often used to process sports and camping equipment.

Method of application: Shake the impregnated container well. Keep sprayer upright. The product is applied to a clean surface, well-degreased and dried, from a distance of 25 cm. The product must dry well. Processing must be carried out regularly.

Special impregnation

In addition to universal, there is a special water-repellent impregnation for the fabric. What is the difference between them? It is very important not to confuse these funds, the consequences can be unpredictable. So, a special impregnation for smooth skin cannot be used for processing products from suede, nubuck. Grease and wax can stick together the fibers and ruin the material. But on smooth skin, these same components have a beneficial effect, protecting the surface as much as possible from moisture.

How to choose the best remedy?

Which impregnation should I prefer? Particular attention should be paid to the release form. Many believe that water-repellent impregnation for shoes from a jar is used more efficiently, since it contains the maximum amount of fat that provides protection from moisture. It can be goose fat, seals or mink oil. These substances can be used in aerosol water-repellent impregnations, but their concentration there is much less.

If you need water-repellent impregnation for suede, then you should pay attention to universal remedies. However, not everything is so primitive. Sometimes, instead of fluorocarbon resins, manufacturers use cheap silicone, in this case, the impregnation can have the opposite effect, that is, it creates an invisible water-repellent film, but at the same time prevents the shoes from breathing. Particles of fluorocarbon resin spread between the fibers, moisture remains on the surface in the form of small droplets.

Before buying the impregnation, carefully study the composition. Streamlined names (water-repellent components, water-repellent emulsion) should be alarming. Conscientious manufacturers write the correct composition on the label, including fluorocarbon resins or fats.

The use of impregnation in sports

Everyone knows that the treated tissue retains its hydrophobic properties for no more than a year. An integral part (waterproof apron) in a sports boat must strictly fulfill its purpose, that is, protect the kayak from excessive flooding. Sewing a protective apron is easy, it is much more difficult to properly process it, to protect it from moisture. There are many recipes for how to prepare a water-repellent impregnation with your own hands. Often used components such as synthetic resins, wax, paraffin, fats, polystyrene, polyisobutylene. Below is a recipe that was used to make the impregnation back in 1958. Studies have shown that treated aprons were waterproof throughout the summer season.

So, the components used:

- A solution of paraffin in turpentine 15-20% - 100-200 hours.

- A solution of polystyrene in toluene 12% - 100 hours

- A solution of low molecular weight polyisobutylene in toluene 4% - 400 hours

- Solvents (turpentine and toluene) - are added if necessary to obtain the desired consistency.

The fabric is impregnated with a uniformly obtained solution, dried in natural conditions. If in some places the fabric begins to leak water, the impregnation must be repeated.

General points on the use of various water-repellent impregnations

Many types of protective equipment are on sale. It can be water-repellent impregnation for seams, for fabric, for clothing, for shoes, for tents, for building materials. The choice accordingly depends on what the tool is for.

Very often, new shoes, equipment, and clothes have already passed DWR processing, but manufacturers recommend using water-repellents additionally before use.

Any impregnation is applied to clean material. According to the methods of application, they are divided into two groups.

The first is the impregnation that is added to the water. The thing is immersed in the solution and rinsed in it. Naturally, shoes are not handled like that. These products are packaged in ordinary containers with lids. The advantages of such material processing are complete impregnation. The washing, rinsing and impregnation process can be combined. Immediately after washing and rinsing, the thing must be treated with the composition, and then dried.

The second is the impregnation applied with a spray or sponge. Hydrocarbon solvents are often packaged in aerosol containers, water-based impregnation - in bottles with a mechanical spray. Such tools are used quite simply - they are applied to a clean surface. Hydrocarbon solvents are used in well-ventilated rooms or in fresh air, water impregnation is best applied to a damp surface.

How often is water repellent applied? As needed. If shoes or clothing are leaky in places, you can use an aerosol or spray gun for topical use. If the majority has lost their water-repellent properties, it is better to use impregnation for complete immersion.