To regularly monitor the fuel level in the car and not get into an unpleasant situation on the road, all types of vehicles are equipped with a special sensor. This device determines how much gas or diesel is left in the tank and for how many kilometers it will last. Each driver should know what a fuel level sensor is - a fuel level sensor, where it is installed and the principle of its operation.

Location

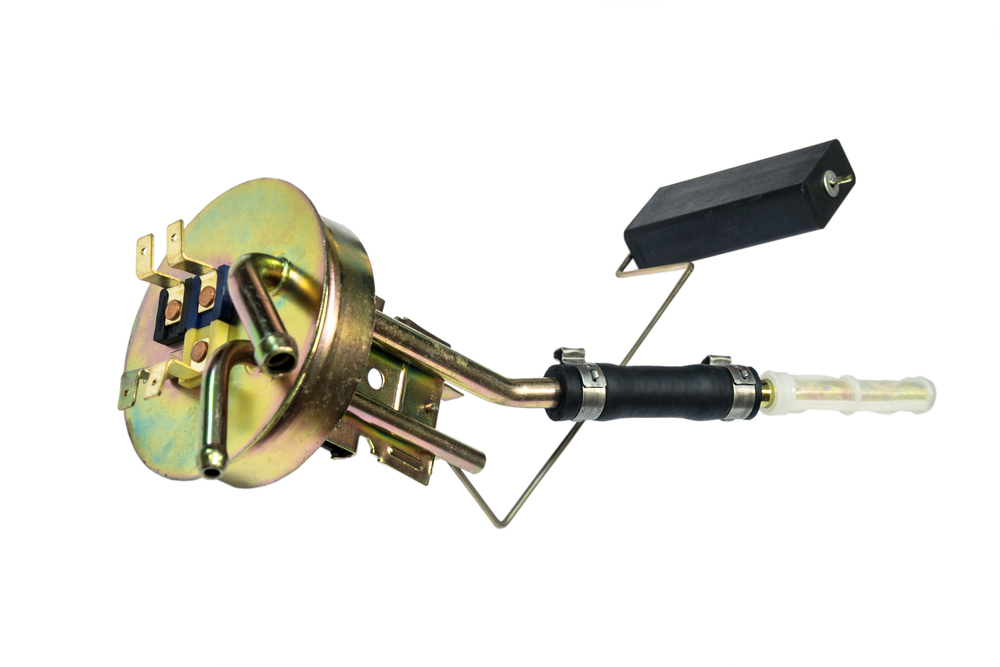

The sensor is located in the fuel tank and is a metal probe with an electronic head, on the screen of which digital indicators are displayed. The part does not move in the tank and does not wear out, designed for tanks with a depth of 40 centimeters to one and a half meters. Digital FLSs are fairly accurate, with an error of no more than one percent. To understand what FLS is, we will learn how it works.

Specifications

A float hanging from an electronic device is placed inside the tank, it always floats on the fuel surface and is directly connected to a variable resistance resistor. When fuel is consumed or, conversely, refilled, the sensor readings also change due to internal pressure. There are several types of fuel level sensors, differing by the method of transmitting information to an electronic unit:

- float device;

- sensitive rod transmitting data using a magnet;

- ultrasonic sensor;

- electric capacitor.

On modern expensive brands of machines, ultrasonic sensors using the radar principle are used. Time and impulses of reflections from the liquid and the walls of the tank are detected. To identify and eliminate the breakdown of such a device, a complex computerized examination of the electronics of the car by specialists is necessary.

But what is a FLS operating on the principle of an electric capacitor? The sensor consists of two tubes with holes inserted into each other. Through these holes, fuel seeps in and fills it, changing the capacitance of the capacitor. Automotive fuel and air are electrically conductive, which is why the sensitive sensor instantly responds to changes in readings. When the liquid level decreases, the capacitance of the capacitor itself increases. The tubular float sensor operates according to the same principle: the tube cavity is filled with fuel, and the sensitive float either rises or falls, depending on the amount of liquid.

Fuel sensors also differ in shape, depending on the shape of the tank for which they are designed: a device with a rectangular float for front-wheel drive cars, and with a spherical one for all-wheel drive vehicles.

Data reading

If the car is equipped with an on-board computer, information about the fuel level in the tank is displayed on the screen. The fuel level sensor in the tank sends a signal to the digital converter, turning it into a code, and the computer, after reading it, displays information on the dashboard. Such devices are very accurate, but depend on the correct configuration and operation of the programmable indicator.

If the computer is missing, the data is processed by a special electronic circuit and displayed on the dashboard.

Failure of DUT

There are several reasons why the fuel level sensor does not work:

- the float is not tight;

- bent wire holder;

- depressurization of the housing;

- open resistor;

- the sensor is poorly attached to the tank body.

When the float has lost its seal, the sensor will always indicate that there is no fuel in the tank, if it is there. In this case, it is necessary to replace the fuel level sensor completely or change the float. If the wire holder of the float is damaged, data distortion depends on the side of the bend of the rod. If it is bent up - the indicator will always show that the tank is full, if down - it indicates a lack of fuel. You need to straighten the holder or replace the device. This can happen with frequent driving on rough terrain, when the tank is hit mechanically or during an accident. Damage to the body of the FLS after an accident and the use of low-quality fuel also leads to a malfunction in the readings.

If the variable resistor breaks, then the indicator will show either an empty tank or filled to the brim. This also happens when a wire is broken that connects the device to the display unit. The smell of gasoline appears in the car interior, so you should check the tightness of the DUT, inspect the place of its installation and the integrity of the fuel pipes.

Fuel quality

Poor gasoline or diesel can cause a failure of the FLS. The increased level of sulfur in the fuel causes corrosion of individual elements of the part, which also leads to complete or partial failure.

Mistakes

Incorrect installation of the FLS, tuning and operation of the vehicle can affect the information, distorting it. Therefore, the fuel sensor does not correctly display the fuel level in the tank.

- The sensor is not in the center of the tank. If the meter is not located in the center of the fuel tank, then during driving the liquid splashes in different directions, which leads to differences in the final readings. For cars, the design feature of which does not allow the indicator to be in the middle, special DUTs with a bending tube are sold.

- A rare request for information. When configuring the fuel sensor, we set the range of information request within 15-30 seconds. This will increase the accuracy of fluid control in the tank.

- Rugged terrain. If the equipment is mainly operated on rough terrain with large slopes, then obtaining realistic data on the amount of gasoline is unrealistic.

- The presence of two fuel tanks. Some car models are equipped with two tanks, and if you install one diesel fuel level sensor on two tanks, then the readings will constantly diverge, since during the ride the fuel can be transferred from one tank to another. In this case, two devices are installed and combined using the setup program.

- The tube touches the bottom. When the measuring tube touches the bottom, it deforms, which significantly affects the accuracy of the readings. The device must be fixed so that at least five millimeters of space remains to the bottom.

- Oxidation of the electrical connector. Oxidation of contacts leads to periodic shutdown of the sensor. It is recommended to lubricate the connector with grease.

- Electricity is at the limit. Exceeding the limits of energy consumption by appliances leads to a device shutdown and jumps in the issuance of information. It is necessary to eliminate the cause of the fuse burning - the voltage of the on-board network.

- Faulty tank vent valve. When heating equipment, poor ventilation of the fuel tank will affect the data.

- Sensor setup. It is recommended to perform high-precision tuning of the device every six months, especially when changing the type of fuel.

Part Replacement

To repair the fuel level sensor or replace it with a new one, it must be removed. First you need to remove the minus terminal from the battery and free up the sensor in the vehicle. You may have to remove the mat and part of the upholstery from the trunk. We unscrew the mounting of the safety plate on top of the device, if any, and we clear everything from dust. We mark the wires so as not to forget how to connect them back, and turn them off. We remove the sensor from the fuel tank and remove it.

Installation

Installation and connection of the fuel level sensor are carried out as follows:

- we clean the remains of the old sealant in the place of attachment;

- we apply a rubber gasket to the hole on the tank, combining them;

- insert the electronic unit by lowering the float in;

- tighten the bolts, pre-lubricating the gasket with sealant.

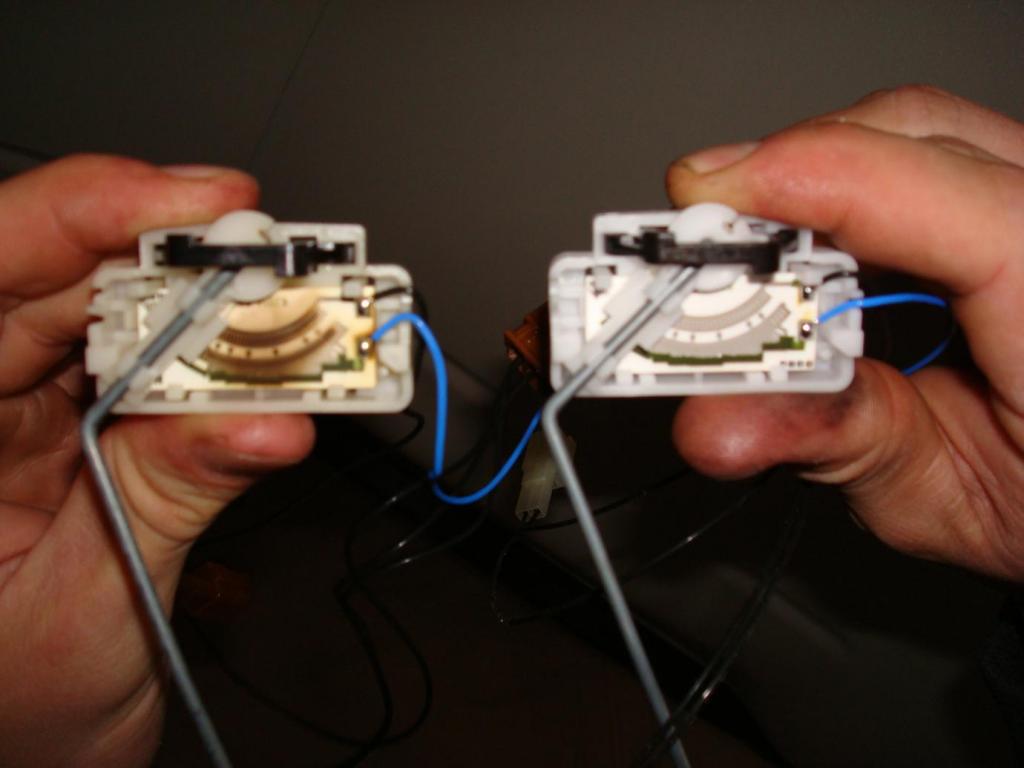

We connect the wires, the battery and start the car, checking the data on the dashboard. Four wires of the DUT are connected in this way to the on-board controller:

- black to black - grounding;

- yellow to yellow - peripheral nutrition;

- blue to blue wire - line B interface;

- white to orange - line A interface.

After driving at least thirty kilometers, you need to check the part for leaks - we look under the boot mat for signs of fuel. For a more accurate check, fill a full tank, the indicator should inform about this.

System Setup

After replacing the faulty sensor, we proceed to configure the system. This process allows you to configure the device as accurately as possible and indicate the amount of fuel consumed in liters. The most common and convenient way is to spill the tank, however it takes a lot of time. You can use the services of specialists in a car service or do it yourself.

A personal computer and the Ls Conf service tool are used for configuration. The device is connected to the computer via the USB port with a special adapter. The sensor readings are recorded when the tank is empty. Then, gasoline or diesel is added in portions of one to twenty liters, until the graph begins to grow up, depending on the volume of the tank, and each time the information is recorded in a special table, according to which then a flow chart is built for a certain period. Refueling and calibration takes place until the entire tank is full. Press the “Save” button so that the calibration table and settings remain in the sensor memory.

Flow control

With the help of such a sensor, entrepreneurs or car owners control the flow rate of working vehicles. So you can determine where the refueling was, the amount of fuel poured into the tank and its consumption per 100 kilometers in order to prevent the abuse and theft of fuel by the driver or other unauthorized persons who may not know what FLS is. This applies to vehicles carrying fuel, transportation companies, freight transportation and so on.