In childhood, I so wanted to make a paper airplane that would fly farthest. If this desire still has not passed or if you want to tell your children the secrets of an airplane, which you can add on your own in a few minutes, for those, this article. In how to make a paper airplane with your own hands, a sheet of paper and a detailed description of the actions will help.

The best do-it-yourself airplanes

Airplanes have always been a symbol of courage, freedom and will. Which of us in childhood did not dream of making the best paper airplane that will fly farther and longer than others. Those peers who knew the secrets of an origami plane were like magicians.

So how to make a paper airplane that flies? Here and now it will be possible to learn the main secrets of a paper airplane, which you can do with your own hands in a matter of minutes and launch it into the air.

The paper used for origami needs to be as thin as possible. Not cigarette, of course, but whatman will not work either, the folds will be of poor quality, uneven and excessively voluminous. Take plain writing paper with the lowest density. Most origami schemes are designed for sheet sizes corresponding to the standard A4 format.

In the manufacture of any model, you need to monitor the symmetry of the parts. In order for a self-made airplane to fly well, accuracy on the folds is necessary: offset, fuzzy and round bends must not be allowed.

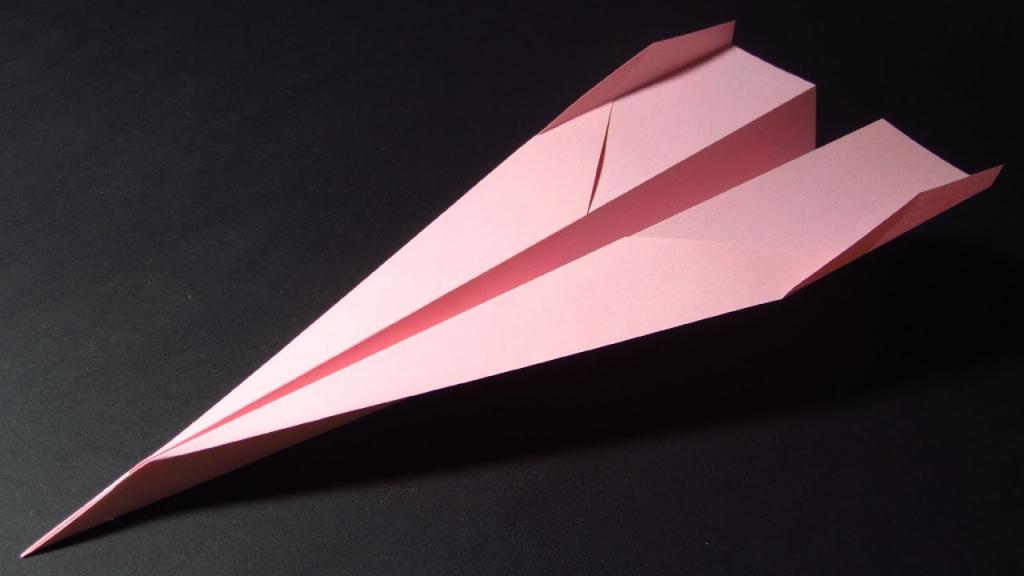

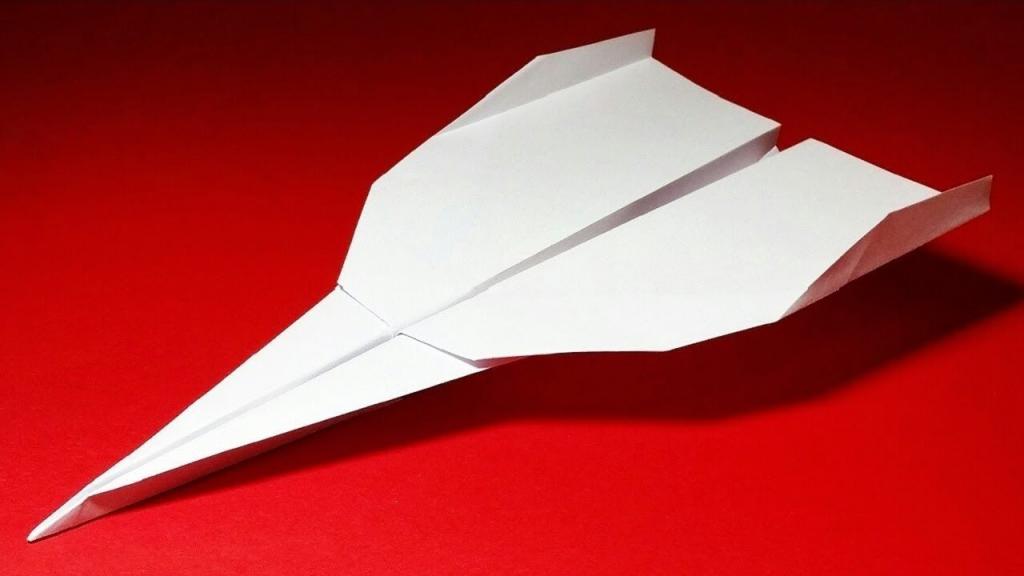

But the main secret is at the tail of the plane. It must be done as carefully as possible and it is imperative to bend the short flaps at the ends. This will ensure a long retention in the air, which means that your airplane will fly far.

The manufacturing time of any, even the most complex aircraft, is no more than half an hour, subject to understandable instructions.

Different models are similar in appearance, but differ in manufacturing details, which are not always given importance. But the desired result most often depends on the details. Therefore, the following are descriptions of paper planes of various levels of complexity; the diagrams describe in detail how to make a paper airplane in stages. Start with the simplest, then making a complex one is not a big deal.

Paper plane of simple difficulty

- For the manufacture of a paper airplane with your own hands, a sheet of A4 paper or commensurate with it in length and width is suitable. Position the sheet in front of you as conveniently and gently fold in half. Check that the fold is parallel to the long side of the sheet, the aligned edges of the sheet should fit perfectly. Gently, pressing a little, stroke the sheet along the fold with your finger. You can bend the sheet in the other direction and once again iron the fold with your fingers.

- Lay the unfolded sheet in front of you vertically. Bend the upper corners alternately so that one of the sides of the corner coincides with the fold line. As a result, the top of the sheet should look like a triangle with a right angle.

- Without turning over the sheet, bend the upper (already folded) corners to the center fold line again. Now the top of the sheet forms an acute angle.

- Fold the resulting workpiece in half along the fold line, with the double-curved corners being inside.

- Having retreated five centimeters from the line of the central fold, you need to bend the “wings” of the sheet parallel to the fold. We got the wings of an airplane.

- At the end of the work, it is necessary to bend the edges of the wings one centimeter wide towards the middle of the workpiece, perpendicular to the lower, wide part of the wing, and parallel to the longest fold line. The plane is ready.

- Check the flying abilities of the model.

How to make a paper airplane of medium difficulty

- Fold a sheet of A4 paper in half in the same way as in the first option.

- It is necessary to fold the sheet across so that the fold lines form right angles and divide the sheet into four equal parts. Gently stroke the folds with your fingers. Make sure the edges of the sheet match perfectly when folding paper.

- Lay the sheet in front of you vertically. Now you need to bend the upper corners to the long fold line so that a triangle forms (as in the previous model).

- Repeat step 3 of manufacturing the previous airplane, you need to bend the corners a second time to the fold lines to form an acute angle.

- Fold the top corner of the paper down, aligning with the fold line. The same thing needs to be done by turning the sheet over on the other side.

- Fold the resulting "nose" in the direction "away from you" along the line of transverse folding of the paper.

- Flip the sheet so that the bent "nose" remains on the bottom of the sheet. Lay the workpiece in front of you with the fold up. For the third time, bend the corners to the vertical fold line.

- Turn the workpiece over and bend the previously bent “nose” to the points of intersection with the sides.

- The plane is almost ready, it remains to form wings. They need to be done in the same way as in the first version: bend the workpiece in a vertical line so that the bent “nose” is just inside the workpiece. 5 centimeters away from the long fold line, make parallel folds on both sides - the wings are ready.

- On the wings, on the lower, widest part, bend 1 cm wide along the main fold in the “upward” direction (or opposite to the bend direction of the entire wing).

How to make a paper plane of high difficulty

In the manufacture of this model, the main and auxiliary lines of the bends are used, so be careful: iron the main lines with a fairly strong pressure, and the auxiliary lines - slightly outlining the bend.

- Just as in the manufacture of previous models, take a rectangular sheet of paper and bend it in half vertically, this will be the first main fold. Further, a number of folds will be auxiliary, they need only be slightly marked.

- Lay the expanded sheet in front of you vertically. Bend the upper corners to the central fold and gently stroke with your finger, these are auxiliary lines.

- Expand the bent corners and bend them, but to the lines of the previous bends, on each side, respectively. It will also be auxiliary lines.

- Now you need to bend the resulting bent corners to the center vertical bend line.

- The resulting corner in the upper honor of the sheet needs to be bent in the direction “towards itself” along the line formed by the lower points of the end of the bend lines of the left and right corners in the previous step. As a result of the bend, the end of the corner will extend beyond the lower edge of the sheet. Be sure to check the alignment of the vertical fold line when folding paper. The resulting transverse line will be one of the main ones, so it can be smoothed out well by bending to both sides of the sheet.

- Next, you need to straighten the sheet and lay it vertically in front of you so that the diagonal folds from the folding corners are in the upper part of the sheet.

- Fold the top corners of the paper to the pre-fold mark closest to the top edge. The resulting line will be permanent, so it can be thoroughly ironed.

- Now bend the resulting side over the upper edge to the center of the sheet. Iron the lines well.

- Next, you need to bend the corner in the direction "away from you" along the main transverse line formed earlier (should pass just below the folded corners).

- Now the corner needs to be bent in the opposite direction, parallel to the lower edge of the sheet, through a point formed by a vertical bend and the combined upper corners folded into a triangle.

- Turn the sheet over. The result was a horizontal rectangle with an angle peering out from under it in the upper part of the structure. Now again you need to bend the formed upper corners to the vertical (central) bend line. Please note that the angle to be stretched will stretch fully to the angle located at the back, it also needs to be evenly laid and ironed. The vertically laid side of the rear structure will not be parallel to the main center line of the fold, this should not confuse the model performer. The same thing needs to be done with the second side. The result should be an angular design that resembles a triangle, but with a curvature drop on the sides.

- Fold the structure in half along the central fold so that the underside of the structure is inside the folded workpiece.

- Now you need to form the wings. To do this, you need to bend each side so that the narrower part of the wing (closer to the “nose”) forms a triangle. The wider part of the wing will thus protrude beyond the line of the main fold.

- As a final touch, you need to bend the canvas in a wide part of the wing at a distance of one centimeter from the edge. It looks like flaps. Iron the outer folds again.

The plane is ready. Long-distance flights to your planes!