As a rule, after fermentation, yeast remains in the brew, which is evenly distributed over the entire volume of the product. They give the liquid a cloudy appearance. If you begin to distill such a product, then a certain part of the yeast will fall into the distillation cube, and later into the finished drink. As a result of this preparation, alcohol acquires an incomprehensible aftertaste that not everyone will like. In addition, the yeast drops to the bottom of the apparatus and can burn, which ultimately does not allow you to evenly heat the contents of the tank. To prevent yeast from entering the apparatus, it is necessary to carry out a procedure such as clarification of mash.

What is it for?

Even experienced winemakers do not always clarify the liquid before distillation. However, such technological methods allow you to remove yeast from the product. If they are not removed, then the final product may acquire a gray and unpleasant to the eye shade. In addition, yeast greatly affects the taste of the drink. Thanks to clarification, you can get absolutely transparent alcohol of a sufficiently high quality.

Natural clarification of the mash occurs a few days after the end of all fermentation processes. Yeast ceases to “work” when about 12% alcohol is formed in the liquid. They fall into suspended animation, and then simply precipitate at the bottom of the tank. Many resort to such a method as lightening the mash with cold. Lowering the temperature to 2-5 ° C helps to ensure that the yeast stops working and settles during the day. However, there are other methods.

Temperature reduction

The ways to lighten the mash are completely different. Moreover, one method can be effective for a sugar product, and the other for grain. You can use cold to cleanse the mash only when its strength is at least 11%. Only in this case, you can not be afraid that the product will begin to sour, even if the clarification by the natural method is somewhat delayed.

For normal cleansing of the mash, a decrease in temperature indicators to 5-7 ° C is required. To achieve this, it is enough to place the container with the brew in the refrigerator. If its volumes are large, then you can put it in the cellar. In such a situation, the cleansing of the drink will proceed more slowly. If there is a danger of vinegar fermentation, then the clarification process must be completed urgently.

The use of bentonite

Very often they make clarification of mash with bentonite. The pros and cons of this method should be considered in more detail. Concrete is a mineral that belongs to the hydrolyuminosilicate group. This substance is often called white clay. Most often, concrete is used in the manufacture of ceramic products, as well as in hydraulic construction. The substance is able to bind various protein compounds into flakes and then cause them to precipitate. Due to this property, concrete is often used in home brewing and winemaking.

The main disadvantage of clarifying the mash in this way is the availability of certain equipment. In industrial conditions, this is not a problem. At home, you can use various household appliances: mixers, blenders, coffee grinders.

Another disadvantage is that it is very difficult to find a special purifier for wine based on bentonite in free sale. However, many experienced winemakers use cat litter, the main component of which is white clay. Such mixtures include Catsan, Zoonik, and Pee-Bent products.

Clarification of mash before distillation with bentonite

It is possible to clean in this way only that mash in which all the fermentation processes are completely completed. Otherwise, there will be practically no effect. Sugar mash is best cleaned in this way. To clarify 10 liters of product, the following proportions must be observed:

- One tablespoon of cat litter filler based on bentonite, pre-ground in a coffee grinder.

- Half a liter of pure water heated to a temperature of 60 ° C.

Powder should be introduced into the water gradually. In this case, the composition must be mixed intensively. The result should be a creamy and uniform consistency. The resulting solution must be carefully and gradually poured into the mash. After this, the product must be left completely at rest for some time. The sedimentation process proceeds within 15-24 hours. After that, the cleaning can be considered completed. In the end, you need to carefully drain the clarified part. To do this, it is better to use a polymer tube.

If clarification is carried out with wine bentonite, then the procedure should be carried out in accordance with the recommendations of the manufacturers. It is worth considering that some brands of purifier must be used in a dry form, without dilution in warm water.

Apply hibiscus

Clarification of mash hibiscus is another popular way. This method is based on the ability of various proteins to precipitate under the influence of acid. In the dry petals of Sudanese roses, this component is abundant. The cleaning process should begin with the preparation of a special solution based on hibiscus tea. To do this, pour a liter of clean water about 70 grams of hibiscus petals and put on fire. Infusion should be brought to a boil. After this, the liquid must be removed from the fire, and then cooled, carefully wrapped in a warm towel.

This amount of components is enough to clean 10 liters of mash. It is recommended to heat the raw materials before the procedure to 40 ° C. Clarification of mash with citric acid, which is part of tea, is carried out for several days. A precipitate falls to the bottom of the tank, it remains only to drain the liquid suitable for distillation.

Features of this method

This method of lightening mash has some features. First of all, a reddish-crimson hue of the filtrate should be highlighted. It is given to hibiscus tea. However, this feature does not affect the taste of the final product.

This cleaning method is ideally suited for the manufacture of grain-based breg. After all, they contain a huge number of particles that are very difficult to filter out. Of course, clarification of hibiscus mash has a clear advantage - it preserves a rather pleasant bread flavor.

Milk for cleaning

The proteins that make up milk have a unique ability. They easily coagulate fusel oils. In the process, distillation creates insoluble compounds. Experienced winemakers recommend conducting clarification of mash only with purified milk. The product must be poured about a few hours before distillation into the liquid in a proportion of 1:10. In other words, this method is optional.

Often a simple discharge from the sediment does not give the desired result. Therefore, it is recommended to carry out additional milk cleaning in combination with filtration, which is carried out in several stages. The first is made using gauze folded in several layers, and the second - more dense cotton material.

How to lighten fruit mash

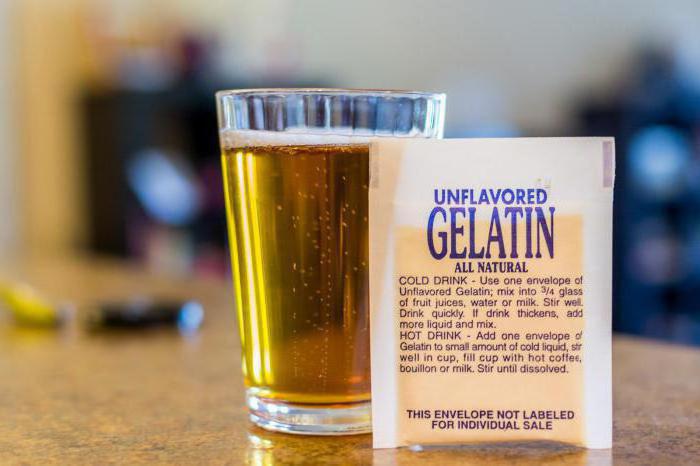

Very often for the preparation of moonshine they use various berry or fruit jam. In this case, lightening the mash with gelatin is suitable. This method is quite simple and does not cause much difficulty. It is worth noting that the cleaning of fruit mash should proceed more gently and sparingly. It is best to use a coagulant of animal origin. These products include gelatin.

A similar method has a clear advantage. Gelatin allows you to make the final product more environmentally friendly. In addition, the method of such clarification requires low financial costs. After all, 10 liters of raw materials require only a few grams of gelatin, which is previously recommended to pour a glass of water, preferably cold. The product should swell. The resulting substance jelly-like consistency must be heated before use, but not boil. Gelatin should completely dissolve. The finished composition should be carefully introduced into the mash. It takes about three days to completely cleanse the raw materials. A similar method is often used in the manufacture of all kinds of fruit wines.

Other methods

Processing mash is a very important stage. To do this, you can use various components, for example, baking soda or chalk. These substances neutralize fermented acids. It is enough to add just a few tablespoons of powder per 10 liters of raw materials. This method is better to use before lightening the mash.

Many experienced winemakers consider such an additional processing of raw materials unnecessary and resort to such procedures only if the acidity of the product is slightly higher before distillation. As practice shows, such manipulations with the braga are necessary. Thanks to this processing, the final product does not have fuselier notes in its aroma, which significantly improves its quality. Experts recommend the use of chalk, since baking soda only affects the pH of the raw material and the taste of the drink. Suitable method for processing grain and fruit raw materials.