The operating conditions of the Niva Chevrolet and the belonging of the model to the category of SUVs determine the need to protect the chassis and engine of the car. Off-road driving and damage to the bottom accelerate the wear of the main mechanisms. It is advisable for the owner of Niva Chevrolet to take care of protecting the engine and gearbox before purchasing an SUV.

Staff protection

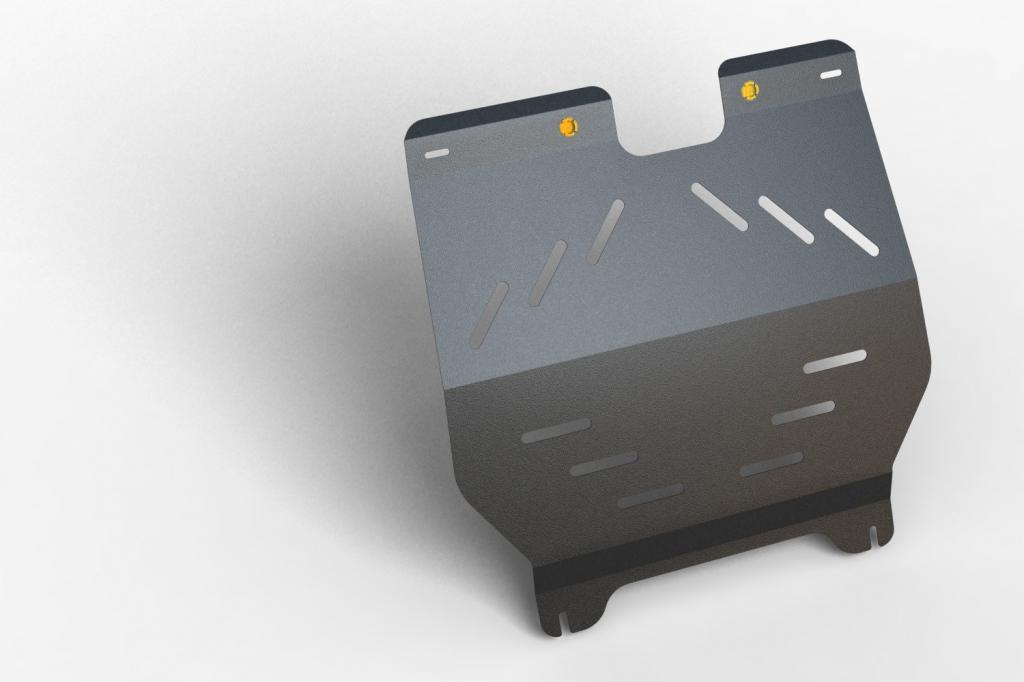

Top configurations are equipped with standard protection of the crankcase and the bottom, made of sheet steel with a thickness of 2-3 mm. The ribbed design provides cooling for the engine, but due to the presence of holes it leads to rapid contamination of the bottom and the need for regular removal of the element for cleaning. The effectiveness of full-time protection is sufficient for measured operation of the car in the city.

When using the Niva Chevrolet as an SUV, it is necessary to install an engine protection of greater strength and reliability, since the standard element cannot cope with serious damage to the bottom when traveling on the road. Protective plates are divided into several types according to the type of manufacturing material.

Types of protection

Chevrolet Niva engine protection is of three types:

- Metal. Nominal crankcase protection installed on top-end configurations or purchased separately in the car shop. Cost - from 3 thousand rubles. Not very effective, sufficient for standard operation of the car in the city.

- Aluminum (duralumin). Two times thicker than metal engine protection. It has less weight in comparison with steel. Resistant to moisture and corrosion. Provides reliable crankcase protection and engine cooling. The disadvantage is the high cost.

- Composite Housing protection with high resistance to mechanical damage. It is more durable, provides better engine protection. It is superior in weight to duralumin analogues. The minimum cost is from 8 thousand rubles.

Motor protection selection

A survey of car owners and monitoring of the main proposals allows us to identify the four main brands of Chevrolet Niva engine protection: Alfa-Carter, Technomaster, Solid Defense Structures and Sheriff. The last two are most popular for several reasons:

- They are made of metal sheets with a thickness of three millimeters.

- Simple design and shape of the elements.

- The thought-over system of fastenings - steel high-strength beams.

- Mortgages with galvanized washers.

- A slight decrease in clearance.

The only drawback is that the nuts of the axles of the front suspension do not close due to the small width of the protection. The advantage of this design is engine cooling and ease of cleaning from dirt.

Sheriff Defense

The design of the protection was developed taking into account the features of the Niva Chevrolet body, engine displacement, clearance, level of patency and other parameters. The optimal ratio of price and quality provides popularity among SUV owners. The cost of protecting the Chevrolet Niva engine is from 2 thousand rubles and more, depending on the configuration, material and type of fastener.

Advantages of Sheriff Defense

- Reliable protection of the engine compartment of the car from damage.

- Resistant to moisture and dirt. Metal wings of the construction protect the crankcase from dust.

- The ribbed surface and openings in the shield provide additional engine cooling and maintain a stable temperature in the engine compartment.

- The powder coating method increases the resistance of the metal to corrosion and damage.

- Rubber shock absorbers located on the edges of the protection minimize noise and vibration when driving an SUV.

- Reducing operating costs associated with servicing the car and eliminating the need for regular dismantling of the protection due to the presence of holes for draining used engine oil and replacing filters.

- The aerodynamic properties of the structure provide the best grip of the car with the track.

- When developing the engine protection for the Niva Chevrolet Sheriff, the design features of the SUV are taken into account. Installation of the element is carried out using reliable fasteners on regular holes.

- High strength is guaranteed by the use of stamping technology in the manufacture of protection.

Mounting Protection

The do-it-yourself Chevrolet Niva engine protection installation work is being carried out at the inspection pit. Before mounting, the bottom and the engine compartment of the SUV are cleaned of dirt and dust, this facilitates access to the mounts.

Installation is carried out in several stages:

- Training. The bottom, engine compartment and standard engine protection of the Chevrolet Niva - if any - are cleaned of dirt. The best option is to use a Karcher sink. To install, you need a set of keys and a screwdriver.

- Measurements. The protection is tried on to the bottom of the car, the compliance of the standard fastenings and holes of the element is checked. The design consists of two parts: the main one for the engine, and the additional one for the transmission.

- Installation Rigidity of protection is provided by fastening on six bolts.

- Verification Diagnostics of reliability of fastenings is carried out.

Recommendations

Chevrolet Niva engine protection is classified by type of fabrication material, method of attachment, and design features. When choosing designs are based primarily on the operating conditions of the SUV. The effectiveness of full-time protection is sufficient only for driving in the city.

Full protection of the engine compartment and crankcase is provided by a duralumin or armored steel structure. Maintenance of the installed element consists in its regular cleaning of dirt.

The nuances of choosing protection

- Installation instructions are supplied with the Chevrolet Niva engine protection. It is advisable to make sure that the manufacturer fulfills the warranty obligations, since the mandatory certification does not apply to security elements, respectively, the certificate may not be attached to the product.

- The thickness, properties, technical characteristics of the material, the number and depth of stiffeners determine the stiffness of the protection.

- Plastic protection fasteners should be equipped with steel sleeves. When choosing a design, you must make sure that it is made of the declared carbon fiber or Kevlar. Verification is carried out by erasing the black paint applied to the surface and determining the color of the fibers: white is characteristic of fiberglass, black is for carbon fabric, greenish-gold is for Kevlar.

- The engine protection of the Chevrolet Niva should be installed on the intended power elements of the body. For this purpose, technological holes are used in the transverse suspension beam, side members, subframe and other structures.

- The thickness of the steel legs and brackets of the fastener protection should be 3-5 millimeters.

- The coating of fasteners must be galvanic - it provides reliable protection against corrosion. The need for this is due to the regular dismantling of the protection in order to clean it from dirt. Spring washers or nuts with nylon rings prevent self-loosening of fasteners.

Operation protection

The likelihood of damage to the gearbox and engine crankcase is not ruled out by the installation of protection - it only reduces the risk of underbody deformation. For this reason, the driving style must comply with the road conditions:

- When exiting from the road to country and dirt roads in poor lighting conditions, it is necessary to reduce the speed.

- Braking in front of obstacles is carried out in advance.

- Water barriers, curbs and level crossings are overcome carefully and at low speed.

- Riding along mowed grass is necessary with caution, since stones, stumps, metal parts, deep furrows and other obstacles can be hidden in it. For this reason, it is advisable to walk the proposed route.

- Objects lying on the track must be circled, and not passed between the wheels, since their size is difficult to determine at a great distance at the entrance.

The main requirements for crankcase and engine protection are strength and rigidity - the resistance of the structure to impact loads depends on them. The mechanical properties of the elements should be aimed at damping the impact force in the event of a collision with an obstacle and preservation of its original shape without deformation. The optimal stiffness of the protection corresponds to the deformation occurring within the gap between the crankcase and the structure - its value does not exceed 20-30 millimeters. A higher value can lead to a decrease in clearance of Niva Chevrolet.