When buying a car (especially a new one), many motorists face the question of choosing a gearbox. And if everything is more or less clear with engines (diesel or gasoline), then the choice of transmissions is simply huge. This is mechanics, automatic, tiptronic and robot. Each of them works in its own way and has its own design features. It should be noted that the variator gearbox is in second place in terms of distribution after automatic transmission. Such a transmission is often found in both Asian and European cars. In today's article, we will look at how the CVT receives owner feedback, how it works, what are its features and pitfalls.

It should be noted that the CVT appeared on the Russian market relatively recently. And if many people know about the machine, then the disadvantages and advantages of the CVT box are not known to everyone. But do not be so afraid of the variator. This is a fairly technologically advanced transmission, reviews say.

Characteristic

So what does the CVT CVT mean? This is one of the types of automobile transmissions whose task is to smoothly transmit torque from the flywheel to the drive mechanisms (and, as a result, the wheels) of the car. Gear shifting as such is not here. Therefore, the CVT is also known as continuously variable. This gearbox provides a change in the gear ratio in the range specified by the computer. The magnitude of the torque depends on the pressure on the accelerator pedal.

Thanks to the special design, such a box is able to maximize the use of ICE power due to the optimal coordination of the load on the car with the crankshaft speed. Thus, high fuel efficiency is achieved. Also among the features it is worth noting a smooth change in torque. That is, the car picks up speed without any jerks and jerks. This has a positive effect on ride.

But it is worth noting that CVT has power limits. In view of this, such a box is used only on cars and crossovers. A vivid example of this is the Nissan X-Trail CVT gearbox. On vans and heavy-duty vehicles, this transmission is not used.

Types

Today, there are several types of CVT:

- With V-belt (sometimes V-chain) transmission.

- Toroid type.

90 percent of cars use the first category CVT. The device and the principle of operation of both types of gearboxes we will consider below. By the way, the first V-belt variator gearbox appeared on the Daf passenger car in the late 50s. Then they began to put a similar box on the Ford and Fiat. Now CVT is on the list of boxes for every global manufacturer:

- "Mercedes Benz".

- "Toyota".

- Audi.

- Subaru

- Honda.

- "Opel".

- Mitsubishi.

- Chrysler

- "Rain."

As for the toroidal CVT gearboxes, they are used on Nissan. According to reviews, this checkpoint is quite expensive to maintain.

Device

The CVT design assumes the following components:

- The mechanism that provides the transmission of torque and the separation of the gearbox from the engine.

- CVT transmission.

- Electronic control system.

- The mechanism that provides reverse movement of the car.

All these components are enclosed in a single metal case. This gearbox is installed in the same way as a conventional gearbox - behind the engine flywheel. To transmit torque and disconnect the transmission, one of three types of clutch can be used in the design:

- Automatic centrifugal clutch.

- Torque converter

- Electronically controlled wet multi-plate clutch.

The most popular type today is the torque converter. This mechanism provides a smooth transmission of torque. In addition, CVT variators have a high resource relative to other CVTs, reviews say.

Belting

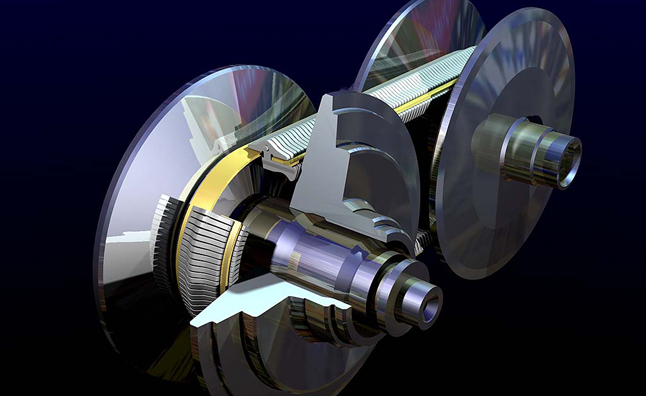

This is the main element due to which the variator works . A V-belt type CVT may consist of one or two belts. A special pulley interacts with them. It forms two conical-shaped disks. These discs can slide apart and slide automatically. This ensures the adjustment of the diameter of the pulley. To reduce the distance between them, the use of spring force, hydraulic pressure and centrifugal force. Typically, the angle of the disc is 20 degrees. This ensures the operation of the belt with the least resistance along the surface of the pulley.

It is worth noting that the first CVTs with such a transmission had a low resource of 50 thousand kilometers. They also had little flexibility (minimum radius - 90 millimeters) and insufficient regulation range. Nowadays, modern CVT uses a metal flexible belt, which is made of ten strips of steel that are interconnected by shaped parts in the shape of butterflies. Torque is transmitted due to the frictional force that occurs between the side surface of the belt and the pulley. This design is characterized by high strength and flexibility. The minimum bending radius is 30 millimeters. At the same time, such boxes do not make noise at all, as reviews say.

V-chain CVT

On variable boxes from Audi and Subaru, a metal chain is used. It is she who is the main driving element and the function of the belt. The chain is a few plates that are interconnected by axes. They have a bending radius of 25 millimeters. In this design, the torque is transmitted in point contact with the conical disks of the end surface of the chain. By the way, the discs themselves are very durable and made of bearing steel. As practice shows, a V-chain variator provides the highest efficiency with the least loss.

Reverse gear

Due to design features, this box cannot provide a reverse stroke. And it doesn’t matter which drive is used - belt or chain. Therefore, to such a car could have a reverse gear, a planetary gearbox is used in the design. It works on the principle of a gearbox in automatic transmission.

The CVT control system also includes a selector lever. He is in the cabin, and it is for them that the driver selects the desired transmission modes.

CVT operation principle

As we said earlier, the torque is transmitted by means of a chain or belt transmission. How does a CVT gearbox work? The principle of operation of the CVT transmission is to change the diameter of the disks depending on the engine load. At the beginning of the movement, the drive pulley has the smallest diameter. In this case, the disks are uncleaned to the maximum. The driven pulley in this case has the largest diameter. With increasing speed and speed, the electronics will change the position of the pulleys relative to each other. So, the diameter of the driven disk is reduced, and the leading - is increasing. This reduces the gear ratio. Thus, the car is gaining more speed. During acceleration, the variator maintains the optimal engine speed (in the region of three thousand). This is necessary for effective acceleration without sacrificing fuel efficiency.

About the Nissan box

On these cars, as noted above, a toroidal variable transmission is used. How is it arranged? Such a box includes two shafts with a spherical surface. Between the latter, special rollers are clamped. The principle of operation of such a box is very simple. It consists in changing the position of the rollers relative to each other in a toroidal surface. The transmission of torque is due to friction between the rollers and the working surface of the wheels.

Is it advisable to use a CVT gearbox? The pros and cons are listed below.

Benefits

The main plus of the CVT-box in the dynamics of dispersal. After all, the electronics themselves selects the optimal torque and gear ratio. A car with a CVT has good speed characteristics. Also among the advantages of the CVT gearbox, reviews note low fuel consumption. It is at the level of mechanics, despite the fact that the whole system works like an automaton. Another advantage that reviews say is a smooth ride. Since there are no gears in the design, jerks and jerks are completely excluded during acceleration. Another plus is high efficiency. It is 10 percent more than the classic automatic transmission.

Problems and pitfalls

Among the problems that arise during the operation of this box, reviews note high maintenance requirements. Every 60 thousand kilometers it is necessary to change the oil in this transmission. And use only the original, since a poor-quality analogue can affect the resource mechanisms. Over the years, the hydraulic block is clogged in the box. Because of this, the pump cannot create normal oil pressure in the system. As a result - slipping shafts. The latter can not normally unclench / clamp the belt or chain transmission. And when slipping, the drive element heats up significantly and wears out. With a high load, the belt can break at all, reviews say. As a result, an expensive box repair is required. Shaft mirrors can also be pulled up. This also negatively affects the action of the drive element. Another minus is the presence of many electronic systems. In the event of a block, it is necessary to fully diagnose the transmission. It’s quite difficult to find an intelligent master who breaks up in the variator (so far these boxes are not widespread in Russia). You have to go to the dealer and pay incredible amounts.

Well, the most significant drawback is the transmission resource. If a conventional automatic transmission walks 300 kilometers without problems (and the old 4-speed models and even more) kilometers, then the variator takes care of half as much. And this is subject to the timely replacement of oils.

Which is better: automatic or CVT gearbox?

Here's what the experts say about this. If the car is new and under warranty, you can safely take it with a variable gearbox. Usually the warranty ends at 100-150 thousand. That is, in case of unplanned malfunctions, you can always fix the problem for free. But if you buy a car in the secondary market, you should pay attention to automatic transmissions.

As a rule, cars with already pretty "tired" CVTs are sold on the "secondary car" and it is simply unprofitable to take them. Automatic transmission has a long resource, and if repair is necessary, it can always be done in any workshop. The cost of work will definitely be lower compared to the variator, and several times.

Conclusion

So, we examined what the variator gearbox has pros and cons, as well as how it is arranged. CVT transmission is more technological than automatic transmission. However, the introduction of new technologies has significantly affected the cost of maintaining the box and its resource. Therefore, it does not always make sense to take a car with such a transmission. In the event of a breakdown, you will have to spend at least one hundred thousand rubles to restore it. Even the most dead machine gun can be brought back to life for a maximum of 60-70 thousand. And then he will serve at least another 200-300 thousand kilometers, the owners say.