The engine is the heart of the car. It is ICE that produces torque, which is nothing but the primary source of all mechanical as well as electrical processes taking place in the car. But the engine is not able to exist without related systems - it is a lubricating system, cooling, exhaust gas, and a power system. It is the latter that supplies the engine with liquid fuel. It can be gasoline, alcohol, diesel fuel, liquefied gas, methane. The engines are different, and they also eat differently. Consider the main types of systems.

Device and functions

Any cars have a certain power reserve. This is the distance that the machine can travel on a full tank without the need for refueling. This distance is influenced by seasonal factors, weather, traffic conditions, type of road surface, car load, driver’s driving style. The main role in the "appetites" of the machine is played by the power system, as well as the correctness of its operation.

There are several basic functions of this system. Regardless of the type of engine, this system performs the function of supplying, cleaning and storing fuel, air purification. She also prepares the fuel mixture and feeds it into the combustion chambers.

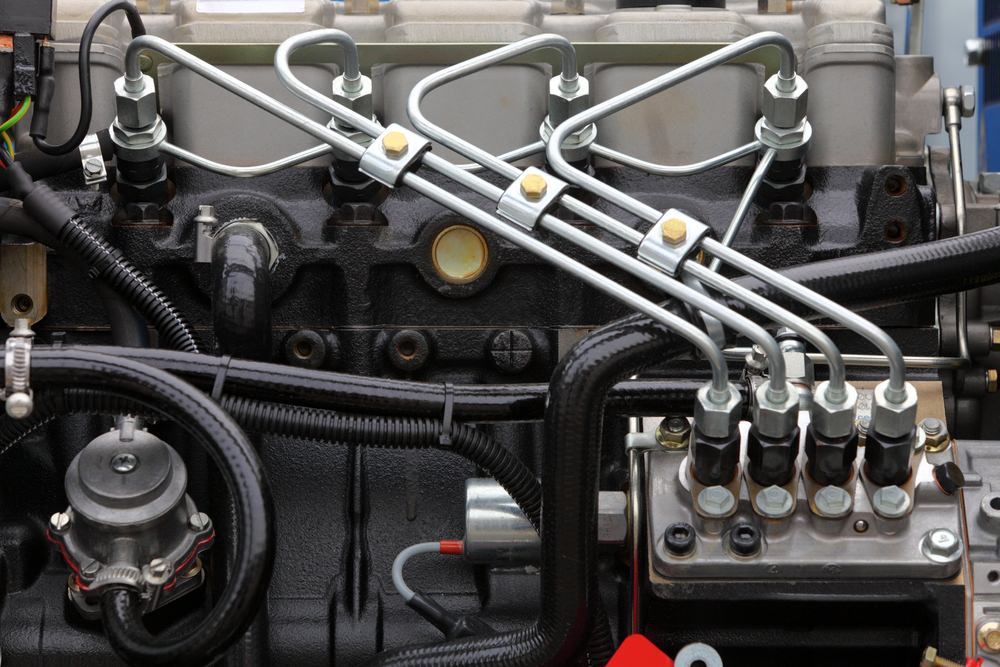

The classic power system in the car is a few elements. This is a fuel tank - it stores fuel. The pump is necessary to create pressure in the system, as well as to supply gasoline forcibly. So that fuel can get from the tank to the engine, the system has a fuel line. These are metal or plastic tubes, as well as hoses made of special rubber. The system also includes filters - they clean gasoline.

An air filter is also part of any fuel system. A special device mixes air and fuel in a certain proportion.

Basic principle of action

The device power supply system of the engine as a whole is quite simple. The principle of operation is also simple. The fuel pump delivers gas from the tank. Previously, the liquid passes through several filters, and then enters the device that prepares the mixture. Further, gas enters the cylinders - in different systems this is done in various ways.

Types of systems

Among the main types of fuel, gasoline, diesel, as well as liquefied or natural gas, can be distinguished. Accordingly, the engine may be gasoline, diesel or gas powered.

Among experts, the typology of automotive power systems is recognized by the method of supply and by the method of preparing the mixture. According to this classification, carburetor systems and injection systems are distinguished. It is a single injector and an injector.

Carburetor

The power system of the carburetor engine has a fairly simple device. It has all of the above elements, and it works approximately as described above. In this case, a carburetor is used as the device that prepares the mixture.

The latter is a fairly complex unit. It serves to mix gasoline with air in certain proportions. In the history of the automotive industry there were many models and types of carburetors. But the most popular are float-type models with a suction principle of operation. These are numerous “Ozone”, “Solexes”, “Weber” and others.

The carburetor circuit is as follows. Naturally, this is a fundamental device. All carburetors are structurally different from each other.

The unit consists of a float chamber and one or two floats. Inside this chamber, fuel is supplied through a needle valve. But that is not all. Also in the carburetor device there are mixing chambers. There may be one or two. There are models where there are four or more mixing chambers. There is also a diffuser and a spray. Float carburetors are also equipped with air and throttle valves. Carburetors are made by casting. Inside there are channels for the passage of fuel and air. They have special metering elements - jets.

The scheme of work here is passive. When the engine piston is at the intake stroke, a vacuum is created in the cylinder. Due to the discharge, air enters the cylinder. The latter passes through the filter, as well as the corresponding carburetor jets. Further, in the mixing chamber and diffusers, the fuel that is supplied from the atomizer is broken up by a stream of air into small fractions. After that, it mixes with air. Then, through the intake manifold, the mixture is fed into the cylinder.

Despite the fact that carburetor engines are considered obsolete, they are still very actively used. Some enthusiasts modify or invent new models.

Injection systems

Engines developed, along with them, power systems improved. Instead of carburetors, engineers invented single-point and multi-point injection systems. The operation of the engine power system of this type is already noticeably more complicated. But they are not always more reliable.

Mono-injection

This is not exactly an injector. It is rather a carburetor with a nozzle and several sensors. The difference is that the fuel in the intake manifold is not supplied by vacuum, but by injection through the nozzle - it is the only one in the entire system. The process is controlled by electronics - it receives information from two or three sensors and, based on this, doses the amount of gasoline.

The system is simple - and this is the main argument against carburetor counterparts. In the fuel system, the pressure is low, and this allows the use of ordinary electric gas pumps. Control via an ECU makes it possible to constantly monitor the amount of gasoline and maintain a stoichiometric mixture.

Electronics works with several sensors. This is a mechanism that controls the opening angle of the throttle, crankshaft position sensor, lambda probe, pressure regulator. Some models also have an idle speed control.

This gasoline engine power system, according to information from the sensors, sends a signal that opens the nozzle. Despite the fact that mono-injection controls the electronics, and its device is quite simple, there are a lot of difficulties with them. Often car owners are faced with an excessive consumption of fuel, with jerks of the car, with failures. Often due to the fact that most of these systems are very old, it is difficult to find spare parts and repair kits for them. Therefore, often owners are forced to return technologically back and install carburetors where there is no electronics.

Even quality service of the engine power system of this type often does not bring results. Due to the age and poor quality of gasoline, these systems have poor viability.

Distributed and direct injection systems

To implement this system, engineers had to abandon one nozzle and use a separate one for each cylinder. In order for the fuel to be atomized efficiently and mixed with air in the correct proportion, the pressure in the system was increased. The nozzles are installed in the manifold after the throttle, and they are directed to the intake valves.

This injection engine power system is electronically controlled. Here, a basic set of sensors is observed, as in a single injection. But there are others. For example, a sensor of mass air flow, detonation and temperature in the collectors. By pressing the gas pedal, the driver delivers air into the system. The computer opens the nozzles due to information from the sensors. The computer also determines the number, intensity and number of cycles that will occur in a single injection.

Diesel engine

The principle of operation of diesel engine is worth explaining separately. There are also nozzles. And diesel is sprayed into the cylinders. In the combustion chambers, the mixture is formed, where it then ignites. Unlike a gasoline engine, in a diesel mixture it burns not from a spark, but from compression and high temperatures. This is the main feature of these ICEs. Thus, high torque and fuel efficiency are achieved. Typically, such engines have low fuel consumption, as well as a high degree of compression (this parameter reaches 20-25 units). If this indicator is lower, the engine simply will not start. At the same time, a gasoline engine can start even with a small compression of eight or less units. The diesel engine power system can be presented in several forms. This is a direct injection, vortex chamber, precamera.

Vortex-chamber and pre-chamber variants supply fuel to a special container in the cylinder, where it partially ignites. Then a portion of the fuel is sent to the main cylinder. In a cylinder, a burning diesel mixes with air and burns out. As for direct injection, here the fuel is immediately delivered to the cylinder and then mixed with air. The pressure in the fuel rail can reach two hundred or more bar. At the same time, the index for gasoline ICEs is no more than four.

Malfunctions

During the operation of the car , the fuel supply system operates under load, which can lead to unstable behavior of the car or failure of various elements of the fuel system.

Not enough fuel

This happens due to low-quality fuel, long service life, and environmental influences. All these factors lead to pollution in the fuel line, in tanks, in filters. Also, in the case of carburetors, gas holes are clogged. Often, fuel is not supplied due to a pump breakdown. On cars with single injection, there may be malfunctions due to electronics.

For stable operation of the engine, regular maintenance of the engine power system is required. It involves flushing nozzles, flushing a single injection or carburetor. It is necessary to periodically change filters, as well as carburetor repair kits.

Power loss

This malfunction of the fuel system is associated with a violation of the proportions of the mixture, which is fed into the combustion chamber. In injection machines, this happens due to the failure of the lambda probe.

In the carburetor, it may be due to incorrectly selected nozzles. As a result, the engine runs on too rich a mixture.

Conclusion

There are other malfunctions of the fuel system. But in most cases, they are connected with other systems in the car. With proper maintenance and replacement of filters, a modern engine will not cause problems to the owner, of course, if this is not an old single injection.