The spatial zone allocated for labor duties at the enterprise or organization is the direct workplace of the employee. In workshops it can be a machine or installation, in the office - a computer desk. The cook has a kitchen with all its contents, the seller has a certain territory of the store with a cash register and counter. Every employee, wherever he works, has a working area assigned to him.

Holy place

How many professions - so many features in the requirements for qualifications, skills, knowledge, one or another responsibility. Everyone has their own workplace organization, and it should help to achieve maximum efficiency from the labor process, promote productivity and quality of products. This is a whole system of measures for equipping the zone with the necessary tools and objects of labor, their placement, and the creation of a general view of the territory. This also includes providing a sufficient workplace with lighting, heating, ventilation systems, a convenient approach / access, ensuring maximum comfort when loading and shipping raw materials or finished products. In other words, the whole range of measures that can provide the proper working conditions for each individual employee, and includes the concept of the organization of the workplace.

In addition, much also depends on the operation or function that a representative of a profession must perform. So, the repairman for refrigeration units has one tool, the one repairing sophisticated digital equipment has another. The placement of equipment or the approach to it for left-handed and right-handed people can also have their own characteristics. Everything is individual, so the requirements for the organization of the workplace also depend on the personal characteristics of the employee. And as the basis for the directions of the whole complex of events, they consider:

- convenience and efficiency of the placement of the necessary equipment or tools;

- comfort of the working area relative to the contributing factors of production labor (lighting, ventilation, heating);

- creating security conditions for the employee not only at the workplace, but also during his entire stay at the enterprise or organization.

Certification of the working area

A few years ago, until 2013, the organization of jobs largely depended on the results of their verification in accordance with the requirements of Article 212 of the Labor Code of the Russian Federation. She regulated such a concept as certification of the area of direct activity of each employee individually. The new Federal Law No. 426 dated 12.28.13 “On the Special Assessment of Working Conditions” derived the term “certification” from the domestic legal base, replacing it with a “special assessment”, and made the corresponding changes to the Labor Code of the Russian Federation. But, in fact, he retained all the basic basic functions of checking working conditions that were in force in the old law, leaving the rules for organizing a workplace almost the same as before 2013.

A special assessment of working conditions implies a certain list of mandatory activities and their clear sequence aimed at identifying harmful or dangerous factors that can manifest themselves in the production process. The audit is carried out directly at the workplace of each individual employee in accordance with the staffing table applicable at the enterprise or organization. The result of the special assessment is the conclusion as far as the studied area corresponds to:

- the requirements and principles of the organization of the workplace, prescribed in the Labor Code;

- equipping with necessary equipment, tools or units for each individual specialization;

- creating comfortable working conditions.

Identified violations should be addressed immediately. In some cases, up to this point, the activity of the zone may even be suspended.

Everything you need at your fingertips

Of great importance is not only the list of everything necessary for work, but also how well the equipment is conveniently located in the area where the employee performs his personal duties. It must also comply with safety conditions. A well-equipped space can increase productivity, reduce power load by eliminating unnecessary movements, and eliminate the feeling of discomfort from poor-quality organization of the workplace. Examples of efficiently equipping the area of activity of certain employees can be found in everyday life more often than we can imagine and to which, as a rule, we usually do not pay attention. How the tools are placed at the hairdresser, how far from the office employee’s desk is the office equipment he needs: a scanner and printer, a landline telephone is equipped under his right or left hand, and how the light falls on the main business area. All these nuances are of great importance.

The territory of the production process or the area of a separate operation must comply with the requirements of the Labor Code. But the law does not prohibit adapting the organization of the workplace. Tools, equipment, if their movement is allowed, may well be rearranged and placed in accordance with the convenience of a particular employee. The main thing is that there should be no complaints from the controlling services and that any movements or replacements of one tool with another do not violate labor legislation.

Job Features

Jobs are divided into many categories. For example, according to the level of placement: indoors, underground or at height. Movable or stationary. With light, heavy or hazardous working conditions. Implies a single, serial or mass process, with a team or individual development. Temporary or permanent activity. The number of shifts at night and daytime, work schedule.

There are many similar qualifications. The respective organization of jobs depends on each specific category. Primary certification or special assessment determines the standards for each of them, and all subsequent ones determine compliance or deviations from accepted standards. Control is important and essential. Therefore, special assessment must be carried out with the frequency established for each category. It can be carried out once a year, sometimes more often, sometimes less. It all depends on the conditions of production and the existing qualifications.

In addition to planning and direct arrangement of production activities, the rules for organizing a workplace also imply its subsequent maintenance. This includes the timely provision of all necessary tools and supplies, qualified equipment setup, supply of raw materials and the types of energy required for the process, scheduled or unscheduled repairs, prevention, and much more. Even shift cleaning and tool cleaning are services, and together with planning, arrangement and control, they make up a complex, multi-stage process of organizing jobs.

Both temporary and permanent

One of the qualification features is the period of production activity: a temporary process or a permanent one is planned. The tasks of organizing jobs in large manufacturing corporations, regardless of the expected period of use of the zone, are not much different. Even for a short time of operation of the site and equipment, the requirements for labor planning and rational use of the territory are quite high. On the production area allotted for this, with thorough thoughtfulness, the main and auxiliary equipment is initially located . The formation of individual jobs is carried out after all large-sized installations or machines are fixed in the sectors allocated to them. Installation and subsequent dismantling bear little resemblance to the temporary nature of their use - everything is solid and reliable.

Such a serious approach is promoted not only by regulatory bodies with their meticulous inspections, but also by the desire of management to secure the work of their employees, to create convenient and practical conditions for them. Reliability in its security and comfort during the main activity contribute to productivity, quality of products, and hence the stable profit that the owners of the enterprise receive. So the approach to the organization of jobs in the workshops of the careful owners is aimed at obtaining the maximum effect from the production process and its results.

Manual and mechanized mode

The number of measures for arranging the working area largely depends on the technological purpose of the production of products, the level of specialization of an individual workshop or enterprise. Given the fact that the process will be mechanized or the bulk of the operations will be carried out manually, the organization of jobs can be conditionally divided into several stages. After the installation of the main equipment, from which all activities originate, the installation of auxiliary, monitoring and protecting devices from possible injury occurs.

The next stage is the arrangement of each specific workplace with lifting and transporting units, metering devices, sensors, and electronics. The following is a complete set of items of technological equipment and tools. The installation of equipment for warehousing and storage of tools, spare parts, auxiliary materials, raw materials and everything else that can be useful in the production process completes the process. A separate, not mandatory, but desirable touch is the creation of a favorable environment by ennobling the territory with flowers, plants, if the conditions and safety rules allow this. The maintenance of the workplace in good condition and cleanliness further in many respects depends on the particular employee.

Protection against harmful and dangerous factors

Through the prism of a multi-stage arrangement of the working territory at a large industrial enterprise, one can get the impression of organizing any other labor zone, regardless of specific professions, if we take an example as a basis. The difference is not significant. All the same several stages, only the volumes and purpose of the equipment are different. And the terms that will be spent on the arrangement will be significantly reduced. However, there are enterprises in which the requirements for the organization of jobs are much higher than elsewhere. We are talking about workshops with harmful working conditions. This may include factories for the extraction of minerals, mines, mines; petrochemical industry enterprises; nuclear plants and the like.

A trouble-free and highly efficient production process in workshops where working conditions are not only harmful but also dangerous, largely depends on the arrangement of the entire territory with alarm systems and means of communication with external security facilities. Features of the organization of jobs here - in picking a single site with all the necessary protective devices. Respirators, goggles, headphones, gas masks, rubber gloves, special overalls, helmets - this is not a complete list of what you may need during the work. For each specialization, a personal list of protective equipment has been developed. All of them are also included in the concept of arranging a workplace.

Landmark - per person

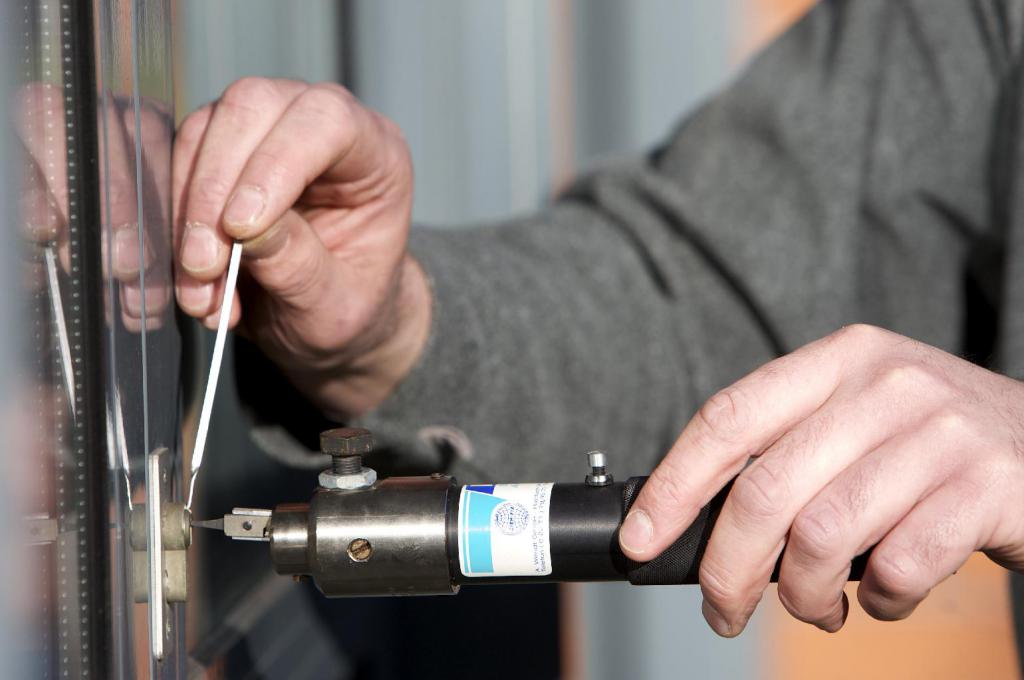

To illustrate the differences in the organization of jobs for individual professions, several examples should be given in comparison with those that can be found in large industrial enterprises. So, at the repairman - the most common representative of the labor collective - their personal area should be equipped with:

- a workbench, machine tool or other specific equipment for performing the bulk of the work;

- rack-stand;

- a bedside table, a bookcase or shelves for tools and appliances;

- a table for small operations and another one for drying tools;

- a chair or a stool.

This is the main thing that should be included in the technical equipment of jobs for repairmen, regardless of their qualifications and specialization of the enterprise in which they work. Of course, the complete set of tools depends on many more specific factors. But there are quite a few of them, and it is not worth giving one example.

And to compare the arrangement of the workplace, a representative of another profession can take, say, a cook. It is also a fairly common area of activity, since all kinds of cafes, bistros, restaurants, eateries today can be found at every step. So, the cook has two main working areas - a cutting table and a stove. Here, the height of these objects is of great importance, since it should not be higher and not lower than the one that will allow you to work without bending or standing on the step. The best indicator is 25 cm from the cook’s bent elbow to the table top. The most commonly used tools should be placed at a distance no further than the outstretched arm, the rest can be located away. Close accessibility should be observed regarding warehousing and food storage. Racks, slides, stands, shelves - everything is arranged in space according to the degree of frequency of use of objects stored on them. And similar rules for arranging the working area are inherent in all other professions from all existing ones.

Quantity or quality and safety?

Not only productivity, but also safety depends on how comfortable the conditions for productive work are created. For a more visual picture of how the workplace should look and what to be equipped with, it is necessary to check from time to time with a map of the organization of labor. It is created at the planning stage of production activities. A document resembling an instruction or a detailed manual is developed for each workplace separately based on engineering and economic research, taking into account current sanitary and hygienic standards, safety requirements and other factors.

The map reflects the most rational layout scheme for a particular site, the sequence of actions of the employee working on it, depending on what operations it should carry out, production standards, the frequency of equipment upgrades and many other nuances. It is enough to look at the map during the next check, and the presence of violations, if there are doubts about this, will become more obvious. The same document most fully describes the basics of the organization and safety of the workplace. Depending on the specifics of labor, the features of engineering analysis, the form and content of the cards may vary significantly, but the number of sections with recommendations, as a rule, is 12 for all.

Workplace - comfort zone

In conclusion, one more fairly illustrative example of the process of organizing a workplace can be given. It can often be seen in movies and various television shows - laying out in a certain sequence of instruments in the operating room that will be used by the surgeon and his assistants. The layout is so established that other doctors do not need to look at what they take from the table. The hands themselves find the desired clamp, tweezers or other tool. Spread them in the wrong order, and the operation can take a long time. In addition, the confusion is quite capable of unsettling the surgeon, which in the process of his work, death is similar. Therefore, this example is so indicative that the outcome of the whole matter depends on the correct and effective organization.

With such scrupulousness, it is necessary to relate to the rational planning of the work process in any profession, whether it be a welder, hairdresser, lumberjack, etc.