For many centuries, the work of jewelers has been very much appreciated throughout the world. Diamond cutting is the peak of their career. Almost everyone knows that diamond is one of the hardest minerals on our planet. The extracted gemstones, as a rule, have an irregular shape, therefore, in order to create excellent jewelry, they need to be given a certain look. Cutting diamonds is a very painstaking and difficult task. During it, everything superfluous is removed from the gem, which allows you to see the true beauty of diamond.

For a long time, when technology still did not allow to process the hardest gem, crystals did not have the beauty that they are acquiring now. Diamonds were only polished and polished, they did not have clear edges, so they did not shine with their graceful beauty. Over time, jewelers learned to give the stones the right shape. They realized that the friction of one diamond against another leads to the appearance of faces, due to which the gloss increases many times. First of all, natural octagonal crystals were processed by uniformly grinding all opposite vertices to form a large flat face. The ancient cut of diamonds was different, but it was octahedral crystals that were most valued.

Over time, diamond processing became more complicated. Jewelers tried to create a large number of faces, because this increased the number of refracted rays of sunlight, which revealed all its beauty. A natural mineral (depending on its configuration) was given the shape of a specific polyhedron with an established orientation of the faces. It is believed that in Europe, the first jeweler to learn how to process diamonds perfectly was Ludwig Van Berken. It was he who in 1475 cut the world-famous Sansi stone.

Diamonds processed by a jeweler are called diamonds. Despite the fact that during grinding work most of the natural stone is lost, its value only increases. Of course, if a jeweler spoils one of the faces, the whole diamond will significantly lose in value. The first stage of jewelry processing of natural stones is their sawing. The quality of diamond cutting depends on the structure of the crystal itself. After sawing the stone, the jeweler sees all the advantages and flaws of the diamond and decides how he will process it further. This process is very time consuming. It often takes days and months (depending on the size of the crystal). Today, diamond cutting is carried out by ultrasound, laser and electronic cutting.

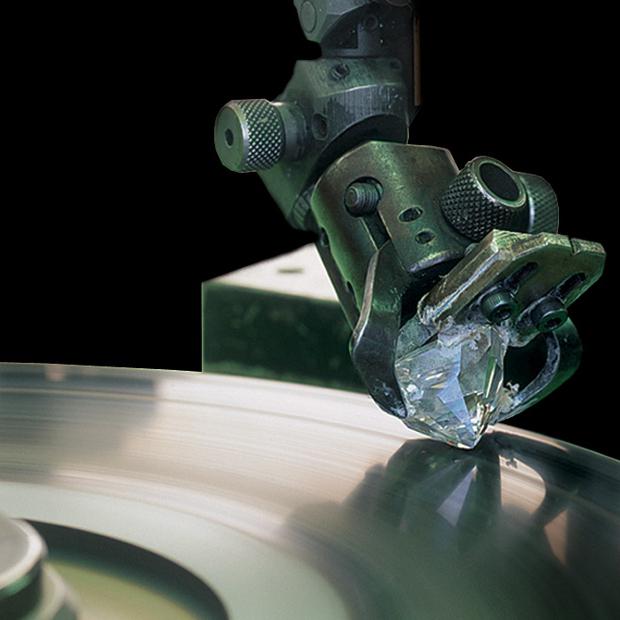

Turning a crystal is an important process during which a certain shape is given to a workpiece. The defects of the stone are eliminated, and it is prepared for cutting. This work is carried out on special machines, invented at the beginning of the twentieth century, but greatly improved today. Diamond cutting is the final stage

of the jeweler's work. During it, the stone is given an aesthetic shape, cracks, punctures and other defects are eliminated. The jeweler carefully polishes the diamond, gives the edges a clear shape, and then polishes them.

Cutting diamonds is a responsible process on which their price largely depends. In addition to working skills, the jeweler must also have an artistic taste. The cutting is carried out using a cast-iron disk, which rotates very quickly. A diamond powder combined with olive or burdock oil is rubbed into its surface. The shape of the stone should be such that most of the light falling into it does not pass through, but is reflected back from mutually arranged faces.

The main forms of diamonds: rectangular (baguette), round / fancy (oval, marquise, pear), a rectangle with cut corners (emerald). The parameters of round and fantasy stones are set during turning, and the rest are achieved during cutting.