Which car assembly is the most important? Almost all motorists will argue that, of course, the engine, as it is he who sets the car in motion. Others will say from the body, about the transmission. But no one will say about the car's suspension. But this is the foundation on which the machine is built. It is the suspension that determines the overall dimensions and features of the body. It also affects which engine will be installed on a particular car.

A pendant is an important and complex assembly. It requires detailed consideration.

Purpose and tasks

A car suspension (also called a suspension system) is a group of individual parts and devices that work closely together. Their main feature is to provide an elastic connection between the road and the car body. The suspension reduces the load on the sprung mass. In this case, the load spreads throughout the structure evenly.

In a modern car, the described system consists of the following nodes:

- Elastic elements that provide a smooth ride and reduce the effect of vertical dynamics.

- Damping element. It converts the load of vibrations into thermal energy, normalizes the dynamics of motion. A guide element in the suspension is necessary for processing the lateral as well as longitudinal kinetics of the moving wheels.

Regardless of the type and design features of a particular car, car suspensions have a common task. It consists in damping incoming vibrations and noises, and also in smoothing out vibrations that occur when moving along uneven surfaces. But depending on the characteristics of the machine, the type of chassis will be different.

Device

Regardless of the type of suspension of the car, it consists of the main elements and parts, without which it is difficult to imagine a workable mechanism.

Among them, there are several main ones:

- The elastic buffer, which performs the function of the analyzer. He fulfills the bumps in the road and transfers all information about them to the body. The composition of these nodes may include various elastic elements - springs, springs, torsion bars. They will smooth out the vibrations arising from the ride.

- Distributing parts. They are connected with the suspension and with the body. This allows maximum transfer of effort. These include levers, transverse and dual traction.

- Shock absorbers that allow you to resist elastic elements. There are two types of shock absorbers - two-pipe or single-pipe. The classification also divides these units into oil, gas oil and pneumatic.

- There is also a bar in the vehicle’s suspension device. It provides lateral stability and stabilizes the body. The bar is a part of a complex set of supports and linkage systems that are attached to the body and designed to distribute the load during various maneuvers.

- Fasteners are bolted joints and bushings. The most common fasteners are silent blocks, ball bearings.

Types of Car Suspension

The history of the first systems goes into the deep past. This is the beginning of the 20th century. Then the first decisions performed only connecting functions and all kinetics was transferred to the body. But then, after conducting numerous experiments, various designs were embodied in the iron, which significantly improved the design and increased the potential for future operation. Only a few types of car suspensions were able to reach modern times.

MacPherson

This system was developed by renowned design engineer Earl MacPherson. This design was first used 50 years ago.

It is a lever, stand and anti-roll bar. This type is far from perfect, but at the same time it is affordable and popular - it is chosen by manufacturers for most front-wheel drive budget cars.

Double lever system

Here, the guide block is not one, but two levers. The system can be either diagonal, or transverse or longitudinal.

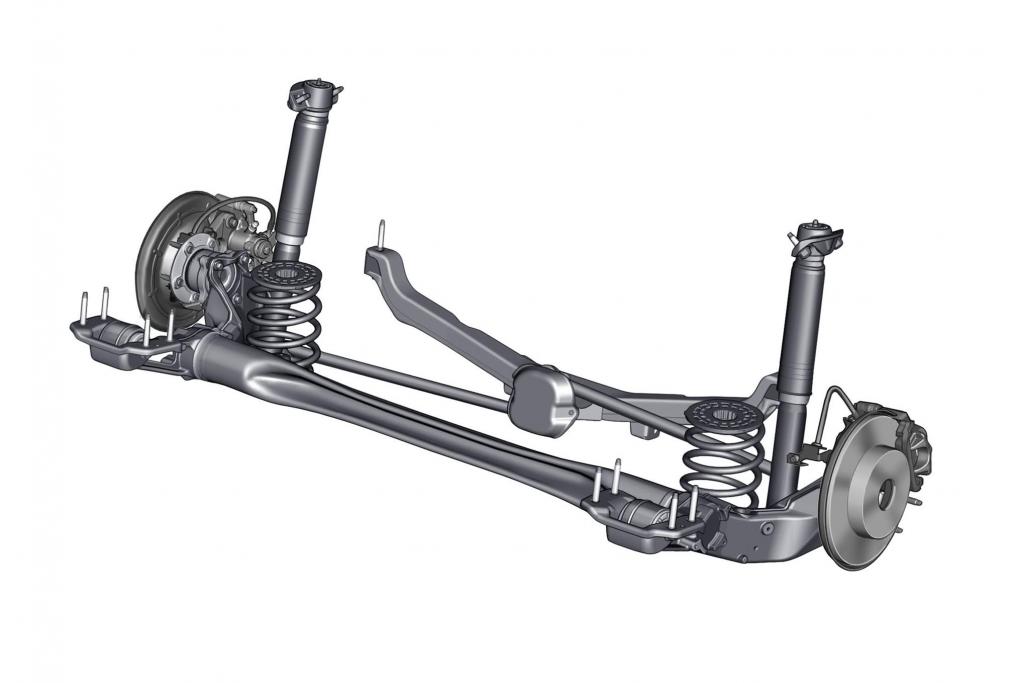

Multi-link

This design is more advanced, and therefore has many advantages. It provides a smooth and even ride, improved maneuverability. More often such solutions are found on premium expensive cars.

Torsion linkage

It is similar in design to the above types of suspension of cars. But in this type, instead of springs, torsion bars are used, which even in the simplest scheme significantly expand the efficiency of the system. The components themselves are easier to maintain, and they can be adjusted at will and according to the tasks to be solved.

Pendant "De Dion"

This design, developed by an engineer from France A. De Dion, reduces the load on the rear axle of the car. Its main feature is that the main gear case is mounted not on the beam of the bridge, but on the body. Such decisions are more common on all-wheel drive vehicles. On passenger cars, this suspension is contraindicated - subsidence at the time of acceleration and braking is possible.

Rear dependent

This is a well-known option for the rear suspension of the car. He was very loved in the USSR.

The beam of this design is mounted using springs, as well as trailing arms. Despite the advantages with excellent handling and stability in motion, there is a drawback. This is a significant mass of the rear beam.

Torsion-lever construction

It is a hybrid of dependent and independent suspension. A torsion bar is used as an elastic element. One end is fixed to the body, the other to the moving part. This design is widely used in most budget cars, because at cost it outperforms the dependent system.

There are semi-independent rear suspension. These solutions use a cross member that is connected by two trailing arms.

Swing axle pendant

In this type, the semiaxes are the basis. Hinges are attached to the end of them, and the axles are articulated with tires. When the wheel moves, it will be at an angle of 90 ° to the axle shaft.

Trailing arm pendants

Designs are divided into torsion, as well as spring. Among the main differences, the wheel is located almost next to the body. Use such solutions on small cars and trailers.

Designs with trailing and trailing arms

This car suspension with trailing arm at the base. It is designed to relieve the supporting forces that are on the body. This type of suspension is very heavy, which makes it unpopular in the modern market.

In the case of the wishbone, everything is much better - the design is flexible with a good and competent setting. Supporting levers reduce the load on the mounting points of the system.

Slanted suspension

Structurally, it is very similar to the design with trailing arms. The difference is that the axes in which the levers swing are here at sharp angles. These types can be found on the rear axle of German-made cars. If we compare this suspension with a design where the levers are longitudinal, then the rolls when turning with oblique levers are lower. This is a big plus.

Double wishbone suspension

Unlike single lever structures, this type has two levers on each axis. They are placed transversely or longitudinally. When connecting them, springs, torsion bars or springs can be used. The suspension is compact, but unbalanced if you need to move on bad roads.

Pneumatic and hydropneumatic suspensions

Double lever systems are most often used in the air suspension of a car. It is not considered an expensive option, but significantly increases driving comfort.

The pneumatic and hydropneumatic type is characterized by a complex device. But it provides a very smooth ride, excellent handling, advanced damping. The air suspension of the car goes well not only with multi-link designs, but also with simple ones like the McPherson.

Electromagnetic systems

This is an even more complex design, which is based on an electric motor. This system solves two problems at once, replacing the shock absorber and the elastic element. The entire complex is controlled by a microcontroller device with a special sensor.

The suspension is safe, and mode switching is provided by electromagnets. This type has a high cost.

Semi-active or adaptive

Here, the suspension cavity adjusts to the surface of the road and the driver’s driving style. It determines the level of damping and automatically adjusts itself to the desired mode of operation. Adjustments are made using electric magnets or fluids.

Suspension systems for pickups, trucks and SUVs

When developing trucks, engineers used options where the axles are placed on transverse or longitudinal springs. Moreover, some manufacturers do not change this design, although progress has reached this area.

Now there are models where a fully hydraulic running gear is used. A distinctive feature of the described suspension of the truck are simple bridges that are attached to the body using a bracket, and are connected using springs.

On SUVs, as well as on pickups, everything is more complicated and can differ significantly from one model to another. This approach is explained by the need for increased cross-country ability. The spring suspension is the basis of the structures, although spring solutions are also found.

Diagnostics

Diagnostics of the car's suspension should begin with the hood raised:

- While the car is standing firmly on the ground, inspect the condition of the upper supports. First of all, it is important what is the gap between the cup and the body. If it is equal to about one and a half centimeters, then the upper pillows must be changed.

- Next, the car is rocking. If it sways more than two times, it's time to replace the shock absorbers.

- They lift the car and look at the shock absorbers from the side. It is important that there are no smudges on them.

- Then they take the car by one of the wheels and swing it right and left, up and down. In the first case, in the front suspension of the car you can hear the knocking of steering rods or rod ends. With the help of an assistant, you can find out the reason for the knock in more detail. You need to take up the steering rod well and find out where the play is - in the steering rack or in the tip.

- If there are extraneous sounds when rocking the wheel up and down, then it's time to change the ball bearing. But if there are no sounds, then it is not a fact that the ball is in order. It is better to make sure of its serviceability with the help of a mount.

- The wheel is rotated. This is necessary to find out the condition of the wheel bearing. Next, the wheel is spun again, with one hand holding on to the spring. If there is vibration on it, the bearing will soon fail.

- With the help of a mount under the machine, the silent blocks are checked. They are moved in the longitudinal and transverse directions. A slight backlash is permissible, but no more. Strong wear of the ball joint can be seen if you swing the lever near the ball with both hands - there should be no backlash. These backlashes are also noticeable during the movement of the car. When turning the steering wheel, a characteristic knock is heard from under the front part.

- At the end, they check the stabilizer bar of the VAZ car suspension - the condition of the bushings is important. The mount is pushed between the subframe and the stabilizer, and then pumped. If the sleeve is damaged, the stabilizer will walk in it. They also check how the stabilizer is fixed to the levers.

Rear suspension

The diagnostic process of this node begins in the same way as in the first case. There are no ball bearings here, so you can start right away with wheel bearings. Then look at the condition of the shock absorbers. That is all.

You can wait some sounds from the rear suspension for a very long time - it is silent, due to the simple and reliable design. Depreciation of the rear suspension can only be felt through terrible handling.

Conclusion

There are a lot of pendants. They are all different, but most are MacPherson. How to diagnose it in a garage environment is described above. But the best thing is not to trust your own feelings, but to go to computer diagnostics, because the suspension is one of the main elements of the car.