In recent years, automation processes in production have become incredibly relevant with more and more new methods, devices and systems being introduced that can reduce the load on a person by shifting it to technology. In many factories, automatic machines appear that perform all the same functions, only with much greater accuracy and with less time. Moreover, it is worth noting separately that automation can reduce the risk for people who previously had to work in incredibly difficult and hazardous conditions. Now they do not need to be at the very epicenter of what is happening - machine operators control them from a distance from a safe room.

Thus, we can safely say that automation is a movement into the future, incredible progress that only benefits humanity. However, this article is not about automation in general, but about what an automation scheme is, how it is made up and how it is used. For many people, this concept may seem strange. Almost no one can just pick up and guess what it is for or what it actually is. All of this will be described in detail below, but first you should understand that the automation scheme is a very important thing, without which the automation process would not be possible.

What is a functional diagram?

Before you deal with the main concept of this article, which is the automation scheme, it is worth paying attention to the fact that more often an adjective “functional” is added to this name. But it doesn’t clarify anything - everything is only becoming more confused. What is a functional diagram? This is the name of the document, which was created in order to clarify and describe in detail certain processes that take place in a single unit or on a specific site. Thus, we can safely conclude that the automation scheme in this case will constitute an explanation (partially even visual) for the automation process in any particular enterprise. Naturally, this is a fairly general definition, so you should go deeper into reading this article, since it will describe in much more detail everything related to this concept, its implementation and application in practice.

Changes in recent years

It goes without saying that everything has its own standard. He has such a concept as an automation scheme: GOST. But it’s worthwhile to understand that standards do not stand still, and this is especially true for such high-tech processes. Over the past decade, the set of technical tools used in the automation process has changed greatly, so the standards have changed a lot.

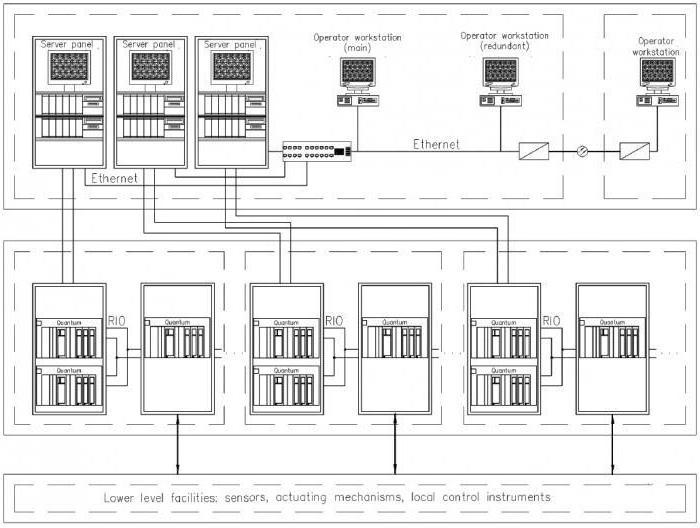

Now automated systems are based on modern super-powerful computers that can demonstrate much more impressive computing power than they did ten years ago. That is why much more extensive functions for automated systems have now become available, including saving results for any period of time, outputting information at any time in a convenient form, creating special detailed mnemonic diagrams that would allow using any parameters for incredibly precise control of almost all possible systems.

Now the controllers have become much more capacious, they can be placed both in specialized rooms in the immediate vicinity of the automated system, and at a remote distance, which allows the use of a much more flexible control system. Thus, you can easily imagine how much a modern automation scheme will differ from a document of a decade ago. GOST 2006 will be absolutely no longer relevant today, in fact, like the automated systems themselves, which can now be replaced by much more efficient ones.

What does the automation circuit look like?

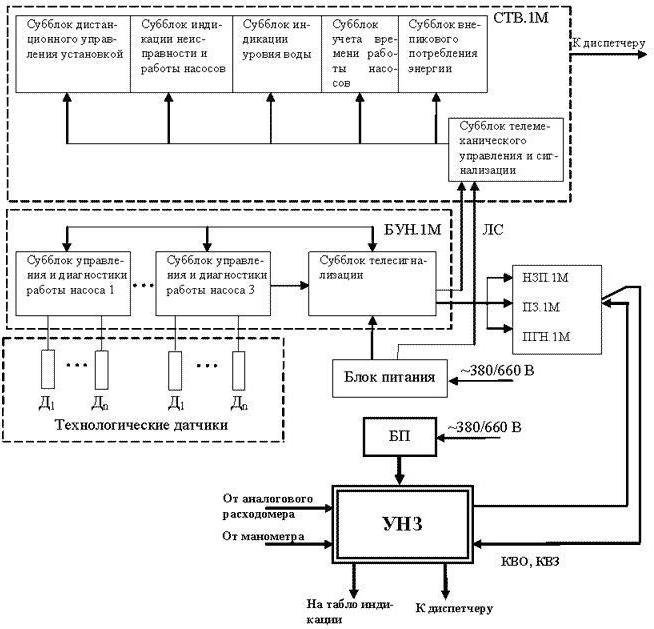

It's no secret that such a scheme is one of the most important documents for the design of automation of an enterprise, workshop or any other production unit. On it, in the smallest details, absolutely everything is described that will include automation, including technological equipment, controls for this equipment, communications and communications between elements and so on.

It is also very important to remember how important the notation on automation schemes is - they are what turn a regular document into a capacious and clear scheme. One look at it is enough to generally evaluate the entire automation process and understand what and how will be implemented. Designations on automation schemes should be as clear as possible, because on the basis of such a drawing other relevant documents will be developed, which will be used in the future. Thus, this scheme, as you already understood, is one of the most important elements of the entire automation process, and its implementation should be at the highest level - down to the smallest detail.

What is shown in the diagram?

Functional diagram of automation is not a detailed image of all elements of production and communication between them. Firstly, it is worth noting that absolutely all elements are displayed on the scheme conditionally, that is, they do not correspond to how they look in reality. Secondly, the scale is not respected, so the circuit has nothing to do with how all the equipment is located in real proportions and proportions. To understand this scheme, you need to understand that this is only a conditional sketch, which gives the viewer an idea of how exactly the elements of the production process function, as well as how they will interact with the automation system.

The automation functional diagram, in principle, has a generally accepted format, so most notations are standardized. For example, according to GOST, it is necessary to depict equipment and communications in thin lines, while technological flows are indicated by more bold ones. There are a large number of different designations, and? to find out all of them, you will have to familiarize yourself with GOST.

Same type devices

Process automation schemes can be very numerous. Depending on how much equipment is included in the plan, how many workshops and departments are a whole, it is worth thinking about optimizing the planning process. And the very first rule applies to devices of the same type. The fact is that usually a scheme includes a large number of elements, since different departments require a different approach. However, if it happens that there are devices of the same type or elements, then they can be described in one diagram, giving a link to it in other sources.

Suppose you have five identical devices that you need to display in an explanatory document. If they are really the same, use the same automation principle. That is, you can create a circuit for the first of these devices, and then indicate that the same scheme is applicable for the other four devices. As you can see, automation control schemes have many interesting and important points that are worth exploring, as they will greatly facilitate your life and make the process much more convenient and efficient.

Legend Tables

It would seem that such a trifle as the conventions of automation schemes should be performed in a relatively free order, but in reality everything is far from the case, and this is very tightly controlled. You need to create a separate table for the symbols, in which there will be two columns - one will contain the name of a specific device, a certain communication, and so on, and the other will show the symbol itself. At the same time, all conditions are quite strict - even the specific width of the columns in this table is set, so that you are not given space for imagination.

Of course, you can come up with your own conventions, but here, again, there are rules of your own, which everyone usually adheres to. That is, there are no specific designations, for example, for connecting pipelines or crossing them, but in most cases it is customary to depict them as lines that are compatible with each other, as well as using one continuous and the other broken or with the help of two lines, one of which makes a semicircular bend at the intersection. But you should remember that even if you use a common designation, you still need to mark it in the table of symbols. Only in this way are the functional diagrams of automation tools carried out.

Letter designations

One of the most important points in matters of automation schemes, regardless of whether it is a functional table or a basic automation scheme, are letter designations. They play a very large role and carry an impressive amount of semantic load, so you should definitely study what this or that letter can mean, which will be written under certain conditions. First of all, pay attention to the fact that the same letter can have several meanings. For example, it can be used to indicate a measured quantity and at the same time a functional sign of the device. Yes, most letters have one of the two designations described above. For example, “A” indicates an alarm, and “E” indicates an electrical quantity. But there are also letters that can describe both one and the other section. For example, “H” - this can be a manual action, and the upper limit of the measured value.

Moreover, some letters indicate only the measured value, but at the same time they can still take two values - primary and secondary. More precisely, this can be the main designation of the measured value and an additional one that clarifies the measured value. To make it clearer, you can give an example with the letter "D". The main value that it denotes in such drawings is density. But at the same time, it can also have an additional designation for a different quantity. In this form, it will indicate the difference or difference. In general, special attention should be paid to letter designations, especially considering that they are also used by the above-mentioned fundamental as well as structural diagrams of automation.

Two methods for creating schemas

Automation system circuits can have two designation methods, and this is a very important point. They strongly influence how the whole scheme will be composed in the future. So, the method can be simplified and expanded. In the first case, the scheme is simplified to a minimum. Specifically, this is expressed in the fact that all the automation tools included in the plan are depicted identically, that is, there are no specific symbols for them. As for the second method, here everything is already much more complicated and diverse. Each automation tool is applied to the circuit with its own designation, which, of course, is written in a separate table, which was already discussed above.

Both approaches are widely used, just each of them is used depending on the situation. In some cases, it is much more convenient to make a sketch in which all the automation tools will be indicated as one element. This will allow you to have an idea about the system as a whole. But sometimes a deeper understanding of the automation process is much more important, so every detail of the circuit looms separately. However, it is worth recalling that even in this case, the scale is not respected. For each type of circuit, full automation may well be carried out. Technological schemes can be a lot, but they do not have some kind of averaged appearance. Each one looks a little different, even taking into account the fact that a lot of it must comply with accepted standards.

Automation Graphics

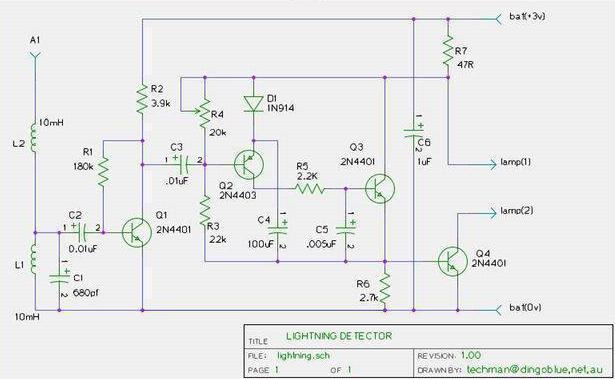

A functional flowchart for process automation can include a huge number of notations, but there are those that you will see there quite often. We are talking about designations that are tied to specific automation tools and devices that are widely used in modern systems. Naturally, there are simply a huge number of species, and now it makes no sense to list them all. But you can imagine a few basic ones, such as a primary measuring transducer, which is depicted extremely simply - using a circle. But if you see a circle that is divided by a line in half, then it will be a completely different device - a device that is installed on the control panel.

If you see a circle from which a straight line goes down, then this means that the actuator is in front of you - but this is only a general designation. There are several types of actuators, and for each of them, the symbol is converted by additional elements, for example, an arrow on the end of a straight line with one of the sides, two short straight lines, crossing one long straight line perpendicularly, with a letter in the center of the circle and so on. The regulatory body is designated as a kind of "bow" - two triangles that touch one of the peaks. It is also worth noting a selective device that does not have a device permanently connected to it. It is indicated by a semicircle with a straight line extending from it.

Numbers on the diagram

So far, we have been talking exclusively about graphical notations that you can find on a functional automation diagram, and we also talked about letters that can and should be used on these diagrams. However, do not forget that the numbers can also be used in the preparation of such a drawing. You should understand that absolutely everything should be marked on the functional diagram, and the more ways of designation are available, the better and the more understandable the circuit will come out. Therefore, you should definitely use numbers, as their advantage is the fact that no values are assigned to them. You will need to create a complete table in which you describe what value is attached to a particular figure. It should be remembered that it is best to give similar symbols to related symbols.

An example is the pipeline automation scheme. The numbers on it can denote all substances that flow along certain pipe sections. The number 1 is water, the number 2 is steam, 3 is air and so on. Naturally, each scheme has its own specialization, so these notations are just an example. You can freely choose how to designate this or that element of your scheme using numbers.

As a result, we can say that automation is a very important and widespread process today, which plays a very serious role in the development of industry, in production and in any field of activity in general. So drawing up a competent and accurate functional automation scheme is also a very useful skill, because thanks to such documents the automation process is much faster and more efficient. A detailed and clear automation scheme is the key to the high-quality implementation of the plan and the further functioning of automated production. Therefore, such close attention is being paid to this issue today.