Thermal energy occupies a special place in human activity, since it is used in all sectors of the economy, accompanies most industrial processes and people's livelihoods. In most cases, the waste heat is lost irrevocably and without any economic benefit. This lost resource is no longer worth anything, so reusing it will help both reduce the energy crisis and protect the environment. Therefore, new methods of converting heat into electrical energy and converting waste heat into electricity are more relevant than ever.

Types of electricity generation

Converting natural energy sources to electricity, heat, or kinetic energy requires maximum efficiency, especially in gas and coal-fired power plants, in order to reduce CO2 emissions. There are various ways of converting thermal energy into electrical energy, depending on the types of primary energy.

Among energy resources, coal and natural gas are used to generate electricity by burning (thermal energy), and uranium by nuclear fission (nuclear energy) to use steam energy to rotate a steam turbine. The ten largest countries of electricity producers for 2017 are presented in the photo.

Performance table of existing systems converting thermal energy into electrical energy.

No. | Generation of electricity from thermal energy | K.P.D.,% |

1 | Thermal power plants, CHP | 32 |

2 | Nuclear power plants, nuclear power plants | 80 |

3 | Condensation Power Plant, IES | 40 |

4 | Gas turbine power station, GTES | 60 |

5 | Thermionic converters, TEP | 40 |

6 | Thermoelectric generators | 7 |

7 | MHD generators of electricity in conjunction with the CHP | 60 |

The choice of the method of converting thermal energy into electrical energy and its economic feasibility depend on the need for energy, the availability of natural fuel and the adequacy of the construction site. The type of generation varies throughout the world, leading to a wide range of electricity prices.

Problems of traditional electric power industry

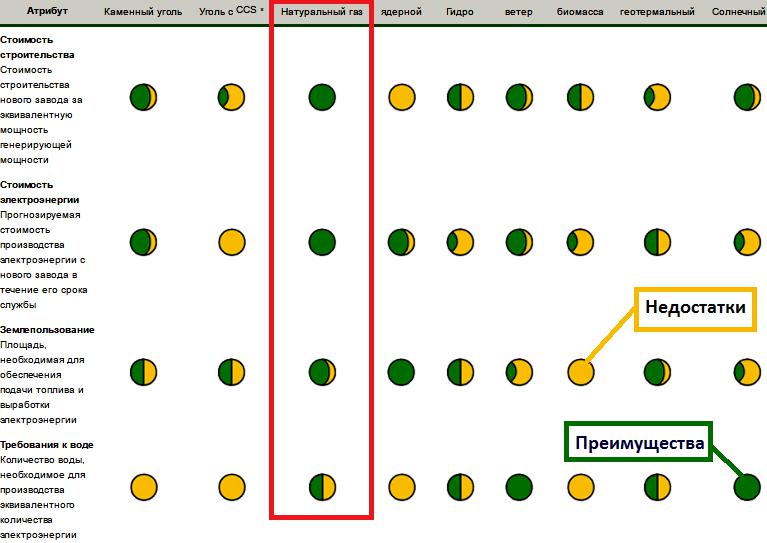

Technologies for converting thermal energy into electrical energy, such as thermal power plants, nuclear power plants, KES, gas turbine power plants, TEC, thermoelectric generators, MHD generators have different advantages and disadvantages. The Electric Power Research Institute (EPRI) illustrates the pros and cons of natural-resource-based generation technologies by addressing critical factors such as construction and energy costs, land, water requirements, CO 2 emissions, waste, affordability and flexibility.

EPRI results emphasize that when considering electricity production technologies there is no single approach to solving all problems, but at the same time, natural gas, which is available for construction, has lower cost of electricity and creates less emissions than coal have more advantages. However, not all countries have access to plentiful and cheap natural gas. In some cases, access to natural gas is at risk due to geopolitical tensions, as was the case with Eastern Europe and some countries of Western Europe.

Renewable energy technologies such as wind turbines, solar photovoltaic modules generate emission electricity. However, they usually require a lot of land, the results of their effectiveness are unstable and depend on the weather. Coal, the main source of heat, is the most problematic. It leads the way in CO 2 emissions, requires a lot of clean water to cool the coolant, and occupies a large area for the construction of the station.

New technologies are aimed at reducing a number of problems associated with power generation technologies. For example, gas turbines combined with a backup battery provide a reserve for unforeseen circumstances without burning fuel, and recurring problems in the field of renewable resources can be mitigated by creating an affordable large-scale energy storage. Thus, today there is not a single perfect way of converting thermal energy into electrical energy, which could provide reliable and cost-effective electricity with minimal environmental impact.

Thermal Power Plants

At TPPs, high pressure and temperature steam obtained from heating water while burning solid fuel (mainly coal) rotates a turbine connected to a generator. Thus, he converts his kinetic energy into electrical energy. Operating components of a thermal power plant:

- Gas boiler.

- Steam turbine.

- Generator.

- Capacitor.

- Cooling towers.

- Circulation water pump.

- Boiler water pump.

- Forced exhaust fans.

- Separators

A typical layout of a thermal power plant is presented below.

A steam boiler is used to convert water to steam. This process is carried out by heating water in pipes heated by burning fuel. Combustion processes are continuously carried out in the fuel combustion chamber with external air supply.

A steam turbine transmits steam energy to rotate a generator. Steam with high pressure and temperature pushes the turbine blades mounted on the shaft, so that it begins to rotate. In this case, the parameters of superheated steam entering the turbine decreases to a saturated state. Saturated steam enters the condenser, and rotor power is used to rotate the generator that generates current. Today, almost all steam turbines are a condenser type.

Condensers are devices for converting steam into water. Steam flows outside the pipes, and cooling water flows inside the pipes. This design is called a surface capacitor. The heat transfer rate depends on the flow of cooling water, the surface area of the pipes and the temperature difference between the water vapor and the cooling water. The process of changing water vapor occurs at saturated pressure and temperature, in this case the condenser is under vacuum, because the temperature of the cooling water is equal to the external temperature, the maximum temperature of the water condensate is near the temperature of the outdoor air.

A generator converts mechanical energy into electrical energy . The generator consists of a stator and a rotor. The stator consists of a housing that contains coils, and a magnetic field rotary station consists of a core containing a coil.

According to the type of generated energy, thermal power plants are divided into condensing thermal power plants, which produce electric energy and combined heat and power plants of thermal power plants, which jointly produce thermal (steam and hot water) and electric energy. The latter have the ability to convert thermal energy into electrical energy with high efficiency.

Nuclear power plants

Nuclear plants use the heat generated during nuclear fission to heat water and produce steam. Steam is used to rotate large turbines that generate electricity. During fission, the atoms split, forming smaller atoms, releasing energy. The process takes place inside the reactor. At its center is the core, which contains 235 uranium. Fuel for nuclear power plants is obtained from uranium, which has in its composition an isotope 235U (0.7%) and non-fissile 238U (99.3%).

The nuclear fuel cycle is a series of industrial stages related to the production of electricity from uranium in nuclear power reactors. Uranium is a relatively common element that is found throughout the world. It is mined in a number of countries and processed before being used as fuel.

Activities related to the production of electricity, in the aggregate, relate to the nuclear fuel cycle for the conversion of thermal energy into electrical energy at nuclear power plants. The nuclear fuel cycle begins with uranium mining and ends with the removal of nuclear waste. When reprocessing used fuel as an option for nuclear energy, its steps form a real cycle.

Uranium-Plutonium Fuel Cycle

In order to prepare fuel for use at nuclear power plants, the processes of production, processing, conversion, enrichment and production of fuel elements are carried out. Fuel cycle:

- Uranium burnout 235.

- Slagging is 235U and (239Pu, 241Pu) of 238U.

- In the process of decay of 235U, its consumption decreases, and from 238U when producing electric energy, isotopes are obtained.

The cost of fuel elements for VVR is approximately 20% of the cost of electricity generated.

After the uranium has spent about three years in the reactor, the fuel used can go through another process of use, including temporary storage, reprocessing and recycling until the waste is removed. A nuclear power plant provides direct conversion of thermal energy into electrical energy. The heat generated during nuclear fission in the reactor core is used to turn water into steam, which rotates the blades of a steam turbine, driving generators that generate electricity.

The steam cools, turning into water in a separate structure on a power plant called a cooling tower, which uses water from ponds, rivers or the ocean to cool the clean water of the steam-powered circuit. Then, chilled water is reused to produce steam.

The share of electricity generation at nuclear power plants, in relation to the general balance of production of their various types of resources, in the context of some countries and in the world is shown in the photo below.

Gas turbine power station

The principle of operation of a gas turbine power plant is similar to that of a steam turbine power plant. The only difference is that the steam turbine power plant uses compressed steam to rotate the turbine, and gas in the gas turbine power plant.

Consider the principle of converting thermal energy into electrical energy in a gas turbine power plant.

In a gas turbine power plant, air is compressed in a compressor. Then this compressed air passes through the combustion chamber, where the gas-air mixture is formed, the temperature of the compressed air rises. This mixture with high temperature and high pressure passes through a gas turbine. In a turbine, it expands sharply, receiving kinetic energy sufficient to rotate the turbine.

In a gas turbine power plant, a turbine shaft, an alternator, and an air compressor are common. The mechanical energy generated in a turbine is partially used to compress air. Gas turbine power plants are often used as a backup supplier of auxiliary energy to hydropower plants. It generates auxiliary power during the launch of the hydroelectric power station.

Advantages and disadvantages of a gas turbine power plant

The design of a gas turbine power plant is much simpler than a steam turbine power plant. The size of a gas turbine power plant is smaller than that of a steam turbine power plant. There is no boiler component at the gas turbine power plant, and therefore the system is less complex. There is no steam, so no condenser or cooling tower is required.

The design and construction of powerful gas turbine power plants is much simpler and cheaper, capital costs and operating costs are significantly less than the cost of a similar steam turbine power plant.

Permanent losses at a gas turbine power plant are significantly less compared to a steam turbine power plant, because in a steam turbine the power plant of the boiler must operate continuously, even when the system does not load the network. A gas turbine power plant can be launched almost instantly.

Disadvantages of a gas turbine power plant:

- The mechanical energy generated in the turbine is also used to start the air compressor.

- Since the bulk of the mechanical energy generated in the turbine is used to control the air compressor, the overall efficiency of the gas turbine power plant is not as high as the equivalent steam turbine power plant.

- The exhaust gases in a gas turbine power plant are very different from the boiler.

- Before the actual start of the turbine, the air must be pre-compressed, which requires an additional power source to start the gas turbine power plant.

- The gas temperature is quite high at a gas turbine power plant. This leads to the fact that the service life of the system is shorter than that of an equivalent steam turbine.

Due to its lower efficiency, a gas turbine power plant cannot be used for commercial production of electricity, it is usually used to supply auxiliary energy to other conventional power plants, such as a hydroelectric power station.

Thermionic converters

They are also called a thermionic generator or thermoelectric motor, which directly convert heat into electricity using thermionic emission. Thermal energy can be converted into electricity with very high efficiency through a temperature-induced electron flow process known as thermionic radiation.

The basic principle of operation of thermionic energy converters is that electrons evaporate from the surface of a heated cathode in a vacuum and then condense on a cooler anode. After the first practical demonstration in 1957, thermionic energy converters were used with various heat sources, but all of them require operation at high temperatures - above 1500 K. While the operation of thermionic energy converters at a relatively low temperature (700 K - 900 K) is possible, the efficiency of the process, which is usually> 50%, is significantly reduced, since the number of emitted electrons per unit area of the cathode depends on the heating temperature.

For traditional cathode materials, such as metals and semiconductors, the number of emitted electrons is proportional to the square of the cathode temperature. However, a recent study demonstrates that heat temperature can be reduced by an order of magnitude when using graphene as a hot cathode. The data obtained show that a graphene-based cathode thermionic converter operating at 900 K can achieve an efficiency of 45%.

A schematic diagram of the process of electronic thermionic emission is presented in the photo.

Graphene-based TIC, where Tc and Ta are the cathode temperature and the anode temperature, respectively. Based on the new thermionic emission mechanism, the researchers suggest that the graphene-based cathode energy converter could find its application in the reuse of industrial waste heat, which often reaches a temperature range of 700 to 900 K.

The new model, introduced by Liang and Eng, may benefit from the graphene-based energy converter design. Solid state energy converters, which are mainly thermoelectric generators, usually operate inefficiently in the low temperature range (with an efficiency of less than 7%).

Thermoelectric generators

Energy waste management has become a popular goal for researchers and scientists who come up with innovative methods to achieve this goal. One of the most promising areas is thermoelectric devices based on nanotechnology, which look like a new approach to energy saving. The direct conversion of heat to electricity or electricity to heat is known as Peltier-based thermoelectricity. To be precise, the effect is called the name of two physicists - Jean Peltier and Thomas Seebeck.

Peltier found that the current sent to two different electrical conductors, which are connected at two junctions, will lead to the heating of one connection, while the other connection cools. Peltier continued his research and found that a drop of water can be made to freeze at the junction of bismuth-antimony (BiSb) by simply changing the current. , , .

- . , , , , , , .

, , . , , . .

:

- .

- , .

- , MP3-, , GPS/GSM .

- .

- .

- .

- , , .

-

A magnetohydrodynamic power generator generates electricity through the interaction of a moving fluid (usually an ionized gas or plasma) and a magnetic field. Since 1970, MHD research programs have been carried out in several countries, with particular emphasis on the use of coal as a fuel.

The underlying principle of generating MHD technology is elegant. Typically, an electrically conductive gas is produced at high pressure by burning fossil fuels. Then the gas is directed through a magnetic field, as a result of which an electromotive force acts inside it in accordance with the Faraday law of induction (named after the English physicist and chemist of the XIX century Michael Faraday).

The MHD system is a heat engine that includes the expansion of gas from high to low pressure in the same way as in a conventional gas turbogenerator. In the MHD system, the kinetic energy of the gas is converted directly into electrical energy, since it is allowed to expand. Interest in the generation of MHD was initially caused by the discovery that the interaction of plasma with a magnetic field can occur at much higher temperatures than is possible in a rotating mechanical turbine.

Limit characteristics in terms of efficiency in heat engines were established at the beginning of the XIX century by the French engineer Sadi Carnot. The output power of the MHD generator for each cubic meter of its volume is proportional to the product of gas conduction, the square of the gas velocity and the square of the magnetic field through which the gas passes. In order for MHD generators to work competitively, with good performance and reasonable physical dimensions, the plasma electrical conductivity should be in the temperature range above 1800 K (about 1500 C or 2800 F).

The choice of the type of MHD generator depends on the fuel used and the application. The abundance of coal reserves in many countries contributes to the development of carbon MHD systems for electricity production.