Since ancient times, hydraulic mechanisms have been used by mankind in solving various economic and engineering problems. The use of the energy of fluid flows and pressure is relevant today. The standard device of the hydraulic motor is designed to translate the converted energy into the force acting on the working link. The very scheme of the organization of this process and the technical and structural nuances of the unit design have many differences from the usual electric motors, which is reflected both in the pros and cons of hydraulic systems.

Mechanism device

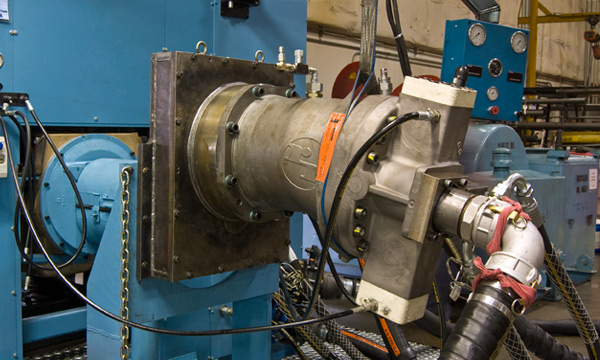

The design of the hydraulic motor is based on the housing, functional units and channels for moving fluid flows. The casing is usually mounted on supporting posts or fixed through locking devices with pivoting capabilities. The main working element is the cylinder block, which houses a group of pistons reciprocating. To ensure the stability of this unit in the device of the hydraulic motor provides a system of constant pressure to the distribution disk. This function is performed by a spring with effective pressure from the medium. The working shaft connecting the hydraulic motor with the output control is implemented in the form of a spline or key assembly. As components, anti-cavitation and safety valves can be connected to the shaft. A separate channel with a valve provides fluid drainage, and in closed systems special circuits are provided for flushing and exchanging working fluids.

The principle of operation of the hydraulic motor

The main task of the unit is to provide the process of converting the energy of the circulating liquid into mechanical energy, which, in turn, is transmitted through the shaft to the executive bodies. At the first stage of the hydraulic motor, fluid flows into the groove of the distribution system, from where it passes into the chambers of the cylinder block. As the chambers fill, the pressure on the pistons increases, as a result of which torque is also formed. Depending on the specific device of the hydraulic motor, the principle of the system at the stage of converting the pressure force into mechanical energy can be different. For example, the torque in axial mechanisms is formed due to the action of spherical heads and hydrostatic bearings on the thrust bearings, through which the operation of the cylinder block begins. At the final stage, the cycle of injection and displacement of the liquid medium from the cylindrical group is completed, after which the pistons begin the opposite effect.

Connection of pipelines to a hydraulic motor

At a minimum, the principle arrangement of the mechanism should provide for the possibility of connecting to the supply and drain lines. Differences in the ways this infrastructure is implemented are largely dependent on valve control techniques. For example, the device of the hydraulic motor of the EO-3324 excavator provides for the possibility of dividing flows with a shunt valve. To control the valve spools, a servo-drive control system with a pneumatic accumulator power source is used.

In conventional schemes, a drain line is used, the pressure of which is regulated through an overflow valve. The distribution (also called cleaning and flushing) spool with an overflow valve is used in hydraulic drives with closed flows for the exchange of working fluids within the circuit. As a supplement, a special heat exchanger and cooling tank can be used to regulate the temperature regime of the liquid medium during the operation of the hydraulic motor. The device of the mechanism with natural regulation focuses on the constant injection of liquid at low pressure. The difference in pressure on the working lines of the distribution hydraulic transmission causes the control spool to move to a position in which the low pressure circuit communicates with the hydraulic tank through an overflow valve.

Gear motor

Such engines have much in common with gear pumping units, but with a difference in the form of liquid removal from the bearing zone. When the working fluid enters the hydraulic motor, interaction with the gear starts, which creates torque. The simple design and low cost of technical implementation made such a hydraulic motor device popular, although low productivity (efficiency of about 0.9) does not allow its use in critical tasks of power supply. This mechanism is often used in control circuits of attachments, in machine-tool drive systems and providing the function of auxiliary organs of various machines, where the nominal frequency of working rotation is within 10,000 rpm.

Gerotor motors

A modified version of gear mechanisms, the difference of which is the possibility of obtaining high torque with small dimensions of the structure. Service of the liquid medium occurs through a special distributor, as a result of which the gear rotor is driven. The latter works on roller break-in and begins to make a planetary motion, which determines the specifics of the gerotor hydraulic motor, device, operating principle and purpose of this unit. Its scope is determined by its high energy intensity under operating conditions at a pressure of about 250 bar. This is the optimal configuration for slow-moving loaded machines, which also impose requirements on power equipment in terms of compactness and structural optimization as a whole.

Axial piston motors

One embodiment of a rotary piston hydraulic machine, in which axial placement of cylinders is most often provided. Depending on the configuration, they can be arranged around, parallel to or with a slight slope with respect to the axis of rotation of the piston unit block. The possibility of a reverse stroke is also assumed in the arrangement of the axial-piston hydraulic motor, therefore, in the layout with the serviced units, a separate drainage line must be connected. As for the target equipment operating such engines, it includes machine hydraulic drives, hydraulic presses, mobile work units and various equipment operating with a torque of up to 6000 Nm at a high pressure of 400-450 bar. The volume of medium served in such systems can be either constant or regulated.

Radial Piston Motors

The most flexible and balanced design of the hydraulic motor in terms of torque control with the generation of high values. Radial piston mechanisms are available with single and multiple action. The former are used in screw lines for moving liquids and bulk solids, as well as in rotary nodes of production conveyors. The radial piston device and the principle of operation of the hydraulic motor with a single action can be reflected in the following functional cycle: under high pressure, the working chambers begin to act on the drive cam, thus triggering the rotation of the shaft, which translates the force onto the actuator. An obligatory structural element is a dispenser for draining and supplying fluid, coupled with working chambers. Multiple action systems are just distinguished by the more complex and developed mechanics of the interaction of the chambers with the shaft and channels of the liquid distribution. In this case, there is a clear, divided coordination within the function of the distribution system for individual cylinder blocks. Individual regulation on the circuits can be expressed both in the simplest valve on / off commands and in a point change in the pressure and volume of the pumped medium.

Linear hydraulic motor

A variant of a volumetric hydraulic motor that creates exclusively incoming movements. Such mechanisms are often used in mobile self-propelled equipment - for example, in a combine harvester device, the hydraulic motor supports the function of executive units due to the energy of the internal combustion engine. From the main output shaft of the power plant, energy is directed to the shaft of the hydraulic unit, which, in turn, provides mechanical energy to the organs for harvesting grain. In particular, a linear hydraulic motor is capable of developing pulling and pushing forces in a wide range of pressure indicators and working areas.

Conclusion

Hydraulic power machines have many positive operational aspects, which manifest themselves differently depending on the specific design of the unit. So, if the gerotor device of the hydraulic motor is simple and does not require significant maintenance costs, then the axial and radial designs in the new versions are more likely to achieve high torques and support the corresponding power indicators, but they cost more in maintenance. For a number of universal indicators, the general advantages of hydraulic machines over battery, electric and diesel devices are observed, but they also have weaknesses, which are expressed in a relatively low efficiency and dependence on indirect factors of the work process. This concerns the sensitivity of hydraulics to temperature extremes, viscosity of the working environment, pollution, etc.