Improving, humanity is constantly facilitating its work, shifting it to artificial intelligence. Robotization of production made it possible to get rid of a number of professions, for example, telephone service is now performed only by electronics, although at the beginning of the last century, female telephone operators connected two subscribers. Today, progress has gone even further, and people began to create real artificial machines that can perform certain mechanical operations - robots.

What is production robotics?

This process should be considered as a component of automation of production, when human capacities are replaced by robotic systems on an industrial scale. Most often, large enterprises try to use universal robots that can positively affect the operation of the entire complex as a whole. Their main advantage lies in the fact that they can be reconfigured at any time for the manufacture of completely different parts and products, it is enough just to introduce another program into the equipment. Through the use of such robotics, many enterprises manage to achieve significant savings.

The process of production robotization plays a huge role in enterprises engaged in the processing of various parts. Up to 50% of production is produced in fairly small batches, and if there are no robots on industrial lines, then the creation of products will take about 5% of the entire working day. The rest of the time will be spent on reconfiguring equipment, replacing parts and tools. Such a functioning of production is not beneficial to any enterprise, since each of them pursues the goal of increasing productivity. The automation of creating parts has another positive effect - robots can save a large number of materials and raw materials, but here it all depends on the rational organization of the work process.

What kind of robots are used in enterprises?

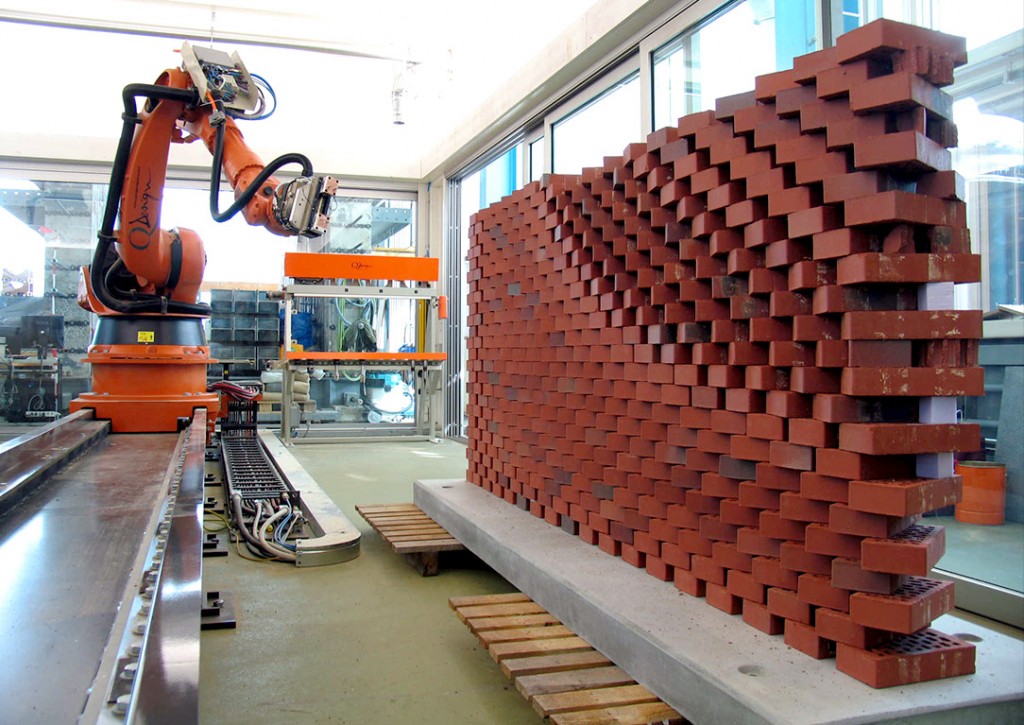

In the manufacturing sector, there is the concept of “industrial robot”, which is understood as a specific device that has a certain number of functions and is able to work on 5 or more programs. The main task of the robot is to fulfill its tasks, namely: manipulating tools, parts and additional materials.

Experienced experts talk about the existence of at least three generations of such equipment. The first generation includes programmable robotics, which can only execute a given program. To the second, adaptive robots that possessed sensors and with their help could receive information from the environment, analyze it, and, if necessary, adjust their own tasks and behavior. The third generation consists entirely of intelligent robots that can distinguish between environmental objects and carry out certain actions on their own. As a rule, when it comes to robotization of production, the company that started it is expected to purchase the most advanced equipment.

Industrial robots are also commonly divided according to their direct functionality. Some of them carry out tasks for the manufacture of products, others - carry out work on lifting and transporting products, others - maintain the main production equipment, etc. Robotics in some cases can perform auxiliary functions, in particular, to clean the premises.

All robots involved in industry are the basis of robotic technological complexes (RTK). The latter are a combination of technology and are most often used to carry out larger-scale operations - capturing the product, performing tasks in extreme conditions (for example, under water), providing information on the progress of related production processes, etc.

Where is automation needed?

Robotization of production should replace human resources, which are most often used to create products and their movement. Most often, the simplest tasks are set for the mechanisms used, which they constantly perform several times a day. You cannot do without the use of robots when packing products, loading and unloading, and also transferring products between different production areas. With the creation of parts, difficulties have been observed so far, since only very expensive equipment can accurately reproduce parts according to the drawing, and its use is so far economically disadvantageous for many enterprises.

If we talk about where production robotics were previously successfully implemented, enterprises involved in welding, cutting, control tests, etc. can be an example of this. Robots are also actively used for simple assembly operations, more difficult processes are still performed by people because they require additional manipulation. The key task of automation of production is to give up simple processes that are repeated several times. Where it is possible to do, robots are procured often enough and serve for a very long time.

What are the benefits of using robots?

The owners of large enterprises have a positive attitude towards production robotics, they consider the pros and cons of this process with particular care, since they have a direct impact on profit. If we talk about the virtues of using robotics, then first of all it is worth saying about productivity. A company with robotics has one undeniable advantage - its workshops can work without interruption for many hours in a row.

With a rational organization of production automation, the amount of monthly production can be an order of magnitude higher. It is very important during robotization to prevent frequent equipment changes, otherwise the amount of profit can be reduced by several times. In addition, the replacement of human resources with robotics can significantly save on wages. To perform all the processes, one operator is enough to control absolutely all systems.

The need to create high-quality goods is another business need that forces enterprises to resort to production robotics; the advantages of using such technology are the high accuracy of the parts obtained. In the adjusted process of creating parts, the amount of rejected material is significantly reduced, in many ways this becomes possible due to the exclusion of the human factor.

It is worth noting the fact that work in some industrial areas is extremely harmful to the human body, and it is here that robotics is simply irreplaceable. We are talking about welding, steel production, painting of materials, etc. The robot installed in the workshop has its own working area, which is formed so that a person can not penetrate into it.

Quite often, students writing WRC “Robotization of industrial production” notice that the use of artificial intelligence can significantly reduce the work space. In some cases, robots can be suspended or even tucked away indoors until next use. The equipment used in industrial enterprises has modern gearboxes and motors; wear-resistant materials are used to create it; due to this, it requires minimal maintenance.

What flaws can be seen in this upgrade?

The relatively high cost of equipment is a significant shortcoming in production robotization; examples and minuses of such a change in production capacities can be traced in almost any enterprise. For example, the cost of replacing one machine is from 500 thousand rubles to several million, and this process requires preliminary financial preparation. If the equipment suddenly breaks, you will have to look for repair money urgently, which is not very convenient.

Another drawback that is most often encountered in modernizing production is the reduction in personnel. Robots are designed to perform low-skilled work and replace people at this post, however, enterprises are not always able to offer their employees an adequate replacement in the form of a new position. According to experts of the World Economic Fund, robots will “squeeze out” from jobs more than 5 million people on the planet in the next two to three years. Such a number of unemployed will need to be built somewhere, and now the largest states of the planet are trying to find the most optimal solutions to this issue.

Developed countries are actively introducing production robotics; they are constantly discussing the pros and cons of this process at international economic forums. As a result of these meetings, new options for the automation of work processes are formed, as well as ideas aimed at organizing new jobs for employees who were left out of work as a result of the introduction of artificial intelligence.

What are the stages of robotics?

Putting artificial intelligence into work at any enterprise consists of four stages, the first of which is technical preparation for changes in production lines. Here it is necessary to take into account absolutely all the features of the company, which will have a certain impact on new equipment. Some organizations use economic and mathematical design, the purpose of which is the introduction of computers for technical mathematical calculations in all departments. The analysis of the activities necessary for the preparation of robotics is carried out manually, so it is not possible to immediately achieve savings, competent optimization and high quality products. If the lion's share of production is served by artificial intelligence, then combining all of the above qualities is much easier to achieve.

Automation and robotization of production can never do without the formation of supervisory control, which always consists of three components: a control structure, a communication system, as well as a measuring and information organization. This unit of the organization should be sufficiently flexible and universal, be able to quickly respond to changing business needs, and also monitor compliance with all the criteria specified in the program. When choosing a system that will control the work of robotics, it is necessary to take into account its accuracy, cost, versatility, as well as a number of other parameters.

It should be noted that the cost of the control component is approximately 60% of the price of an industrial robot, which is why it is necessary to approach its selection with special care. Some enterprises, unfortunately, choose the cheapest control systems - analog and cyclic, this justifies itself only when the company is engaged in the production of bulk goods and equipment rarely needs to be reprogrammed. If you need to create small-scale parts, it is better to use numerical and positional control systems that can be easily reprogrammed.

Next comes the most crucial stage - direct programming. Robotization of modern production involves four stages of control over the work of artificial intelligence: the formation of a cycle, memorization of a program, reproduction and direct execution. Particular attention should be paid to programming, which today is carried out using two methods - analytical and educational. The first one provides for calculations and debugging, after which the operation algorithm is entered into the control system. The second is the creation of a monitoring program already in the working room using a special remote control, which is part of the equipment. Experienced experts advise using both options in order to achieve the best quality effect from robotization.

The final stage is the launch of automated production at full capacity. It is very important to ensure that the production lines work as efficiently as possible, only after all the necessary tests have been completed can robotics be commissioned. Please note that in the first few hours it is necessary to test the available capacities and make the necessary adjustments.

How do robots help with welding?

The era of introducing artificial intelligence began with the robotics of welding production, with its help it was possible to achieve significant results. Industrial machines in the 1970s were refocused on spot welding, and since then it has become their main activity. Since the beginning of the use of robots, the quality of welding has increased several times, which has benefited the industry. Today, the profile from which the parts are made, and the connection point do not play any role, artificial intelligence is able to connect absolutely everything.

Robotization of welding production continues to gain momentum in the 21st century; today, the devices used have additional sensors that can process incoming tactile and visual data. All robots are able to weld two metal surfaces and get a high-quality seam made in a stable arc. Industrialists believe that in the future, such a technique can be used for laser welding, as well as for additional cutting of the processed material.

Can robots be used to create food?

As humanity is constantly increasing its numbers, the question of how to feed everyone is becoming increasingly relevant. Robotization of food production can come to the rescue, allowing to create new high-quality products in the shortest possible time. Among experts, there is a point of view that robots will be increasingly used in this field, and sooner or later they will supplant even professional chefs.

Progress has gone so far that today artificial intelligence is capable of independently processing cottage cheese products: cut, sort and even pack, while the strictest sterility is observed in production. Confectioners are especially fond of using robotics, with its help it is possible to create original and accurate drawings on cakes and pastries, as well as carry out packaging of the resulting products, which saves a lot of time resources. Also, robots are used in the fishing industry, where they help to cut the catch into portioned pieces, which is very convenient for cooks working in the field of catering.

Robotization of food production should affect those areas where employees are exposed to dangerous and harmful environmental influences. We are talking about temperature extremes, humidity, noise, increased vibration and dust. However, experts do not exclude the possibility that robots will be engaged in the creation of food products from scratch, but such artificial intelligence will not be developed soon.

How to automate the work in our country?

If we talk about robotization of production in Russia, then here it is only beginning to gain momentum. Most of the devices are used in welding and loading operations, as well as in the automotive industry. The number of companies using artificial intelligence is growing every year, as their owners have understood all the benefits of implementing automation. As of 2018, in Russia there is only one robot per 10,000 people, however, already by 2025, experts predict an increase in the number of robotics in the domestic industry by 20%.

, . , , - , – - . , , .

, , , . , «» , – .

?

, , 2017 10 70 . – 631 10000 , – 488 – 309. , , 9 7 .

The record holder for the introduction of robotics is China, if in 2013 the average density of devices was 25 units per 10 thousand employees, then by the end of 2016 this figure had already increased to 68 and continues to increase. By 2020, the Chinese authorities intend to enter the top states-leaders of robotics. South Korea is the state with the highest density of robots since 2010, they can not do without them when creating cars and electronics.

The antirecords for production robotics as of 2018 are Russia, India and the Philippines. In these countries, the robotics market is still developing, so equipment manufacturers are actively offering their services to potential customers. Representatives of the engineering and automotive industries show great interest in the use of artificial intelligence, since its introduction will significantly relieve the human resources of companies.

Experts believe that the success of many enterprises in the future will depend on the robotization of production, the scope of automatic machines is constantly expanding and requires more and more research and development. In their opinion, automation cannot be set as an end in itself, artificial machines can be introduced only in those situations where a person for one reason or another cannot do the job better than them. Stabilization of the technical process, increasing the accuracy of manufactured parts and the speed of fulfilling the set goals - all this is only a small part of the reasons forcing enterprises around the world to introduce robots into production.