In some cases, a problem such as drainage of sewage from the facility may occur. Most often this arises due to problems made at the design stage of the sewage system. In such cases, they often resort to such a method of solving the problem as installing a damper.

Need for device

The main purpose of this device is that it must constantly monitor the speed of movement of the fluid flowing inside the pipeline. If we talk about the general design of this device, the damper well is a certain control or regulation unit, without which it is almost impossible to somehow affect the operating parameters of the line.

This device is considered to be most relevant if you have to deal with gravity storm sewers. Most often, in such systems, the liquid travels rather large distances, redirecting from the object to the nearest reservoir or gutter. In such networks, a quencher well is an indispensable and necessary thing, since it can be used to control the flow intensity in a selected area. Thus, it is possible to change the pressure acting on the walls of the pipeline.

General job description

No wonder it is said that everything ingenious is simple. The principle of operation of the quencher well is quite simple, but at the same time very effective and in some cases is an indispensable element.

Initially, the liquid does not immediately enter the sewer pipes, but into the container where the accumulation of the substance occurs. After filling the tank, pumps are switched on that transfer liquid to the sewage, and from there to the sewer. If we talk about the device of ordinary household sewage, then capacity means a sump. If we talk about sewerage autonomous type, then here a drainage type well is used as a reservoir.

The principle of operation of the device

A well-absorber of pressure installed in an autonomous sewer will filter the resulting fluid, and then redirect it to the soil so that it is absorbed. The only thing worth adding is a tie-in to this reservoir of all local pipelines. However, this is relevant only if the village or village has a central water flow line.

The installation of a quencher well for sewage will be most appropriate in the place where the highest intensity of the flowing fluid flow is observed. This place is most often the segment located between the point of location of the pumping equipment of the station and the point of insertion into the system. It is worth noting that the installation of this equipment is most often accompanied by the installation of an additional viewing well. This set of devices will perfectly cope with the task of extinguishing excessive values of fluid pressure in this section of the track.

Operating parameters

As it has already become clear, a pressure quencher for sewage is "engaged" in that it changes the intensity of the flow of fluid flowing through the pipes. That is, to quench the flow, it is necessary to change its intensity, but it is important to note here that this does not help in all cases.

In some situations, it may happen that a markedly too strong head pressure drop is observed. In such places, a defect such as a slight flooding of the system is most often observed. When constructing a sewage system for any object, special attention should be paid to such a question as the analysis of changes in the fluid flow rate through the pipeline. To do this, use hydraulic formulations and meanings.

For typical damping wells, these values are the following parameters: water properties, viscosity, both dynamic and kinematic, pipe length, and pipe diameter in certain sections of the system. In addition, it is necessary to take into account factors such as flow rate, turning radius. This is very important, since these indicators will have a significant impact on the speed of the fluid when it is pumped.

Device device

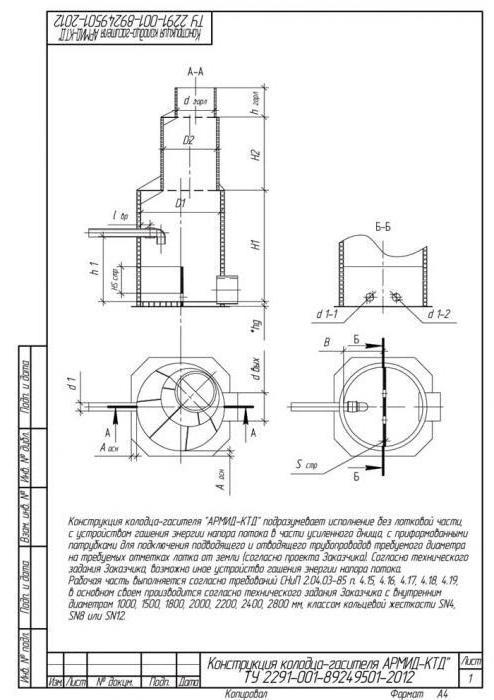

A typical design of a quencher well is the plan by which this fixture is installed. This document may be changed in the course of the work due to the fact that the calculations of this structure for a particular object or specific landscape conditions will be carried out. Engineers must perform a hydraulic calculation, in which it is necessary to take into account such characteristics as the slope of the landscape, the length of the pipe, the parameters of viscosity and fluid flow. This must be done in order to correctly select the diameter of the well, as well as the pipes, to correctly determine the radii of the turning parts, and so on. Documents for typical extinguisher wells should also include papers such as the layout of the pipeline on the ground.

The design of this device is a cylindrical tank with a bottom, to which several pipes are mounted at different heights. Waste water enters the tank through the upper compartment of the pipes, and is discharged through the lower compartment. Thanks to this method of water withdrawal, the pressure is quenched by about 17-20%.

Drawings of the pressure absorber-well should be made with notes, explanations, have a specification of materials, as well as products with a complete calculation of the required quantity.

Why the pressure rises

For what reasons does it happen that too much pressure appears in the pipes? There are two reasons for this.

The first and main reason for this phenomenon is that the whole system was originally planned incorrectly. It may happen that the pipes were selected with a small diameter, and the pump was of a sufficiently large capacity. These factors are already quite enough to create excess pressure. Although this property is directly opposite, and increased pressure can occur due to lack of fluid in the system. There are other reasons for increasing this characteristic, for example, the slope of the sewer pipes is too strong.

Basic installation principles

Sewer damping wells are most often mounted in the area between the pump and the sewage treatment plant. It is important to note here that this device, in addition to its main function, can play the role of a transfer or rotary well.

The first device will be used in order to combine different communications located at different levels. Or this unit can be used to circumvent various obstacles that make it impossible to lay a pipeline in this section. This can be, for example, the foundation of the building, other communications, etc.

The rotary type of well, as its name implies, is necessary in order to rotate the pipeline system. It is important to note here that such places most often become places of a rush. Because of this shortcoming, experts recommend making a mine that will allow you to control the condition of the pipe.

Device installation

In order to install a conventional damper well, concrete rings are most often used. In addition to these materials, it is also necessary to have a concrete base and a cover. It also happens that the moment of installation of the damper falls on the time when the sewer communication of the facility is being laid.

To begin work, it is necessary to prepare the mine. The depth of this section will directly depend on the depth at which the sewer pipes are located. A concrete base is placed at the bottom of the shaft, and then the installation of the rings begins. The pipe is introduced into the well through a pre-prepared hole in the tank. It is also necessary to make one more hole in advance, to which a pipe will be connected, which serves to drain the liquid. Elements such as shock absorbers will provide smoother movement of water into the treatment plant. Thanks to this function, it will be possible to greatly increase the service life of not only the pipeline, but also the cleaning tank itself.