The base of linear measurements in any industrial sector is plane-parallel end measures of length (KMD). They are used to store a unit of length and reproduce it. And also for checking measuring devices, calibrating them and setting them to zero on devices, transferring dimensions for the required settings, and they serve as a natural size meter for all kinds of details. A set of plane-parallel end measures of length allows marking work with special accuracy and setting up the machine. The main function of the KMD is to maintain the unity of measures in various industries.

Basic concepts

Instruments used as measuring instruments at industrial enterprises, repair organizations or services must periodically (on a systematic basis) be checked for accuracy of measurements. Naturally, for verification, it is not possible to deliver the measuring instrument from various industries to institutions where the reference dimensions are located.

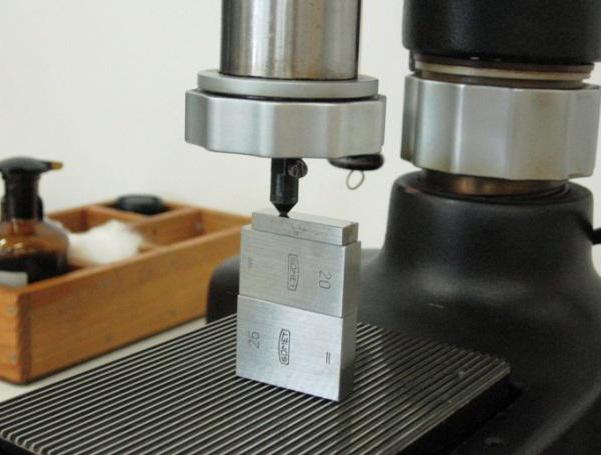

This procedure, without leaving the enterprise, allows you to carry out end measures of length (plane-parallel). They are a model or standard measure of length. Externally, the device looks like a parallelepiped or cylinder with numbered dimensions located between the measuring planes.

The main task of Johanson tiles is to preserve the unit of length and its transfer. Plane-parallel end measures of length are used for calibration, verification and / or dimensioning on various measuring devices (gauge, micrometer, sine bar, indicator, etc.), as well as on control production devices and templates.

Like a hundred years ago

Trailer measures of length were for the first time made by the Swiss firm "Johanson". Made of steel in the form of rectangular parallelepipeds, they appeared at the Paris World's Fair in 1900. Thanks to the manufacturer, the name "Johanson tiles" for a long time accompanied the end measures of length (plane-parallel). A little later they became just “tiles”.

In the Soviet Union, KMD was first produced at the Sestroretsk and Tula factories. They were launched into the series at the Krasny Instrumentalshchik factories in the city of Kirov and Moscow Caliber in the early 30s.

Nowadays, with the advent of non-contact laser interferometers, electrical measuring instruments, long meters, coordinate measuring machines, altimeters and other devices for perfect measurements, the role, purpose and use of CMD have undergone significant changes. Nevertheless, the basic, basic quality - the material medium of size - is still indispensable. And this despite the large number of modern optical and electronic means for accurate measurements.

Plane-end end measures of length (Johanson tiles) are produced with dimensions that are between 0.5 and 1000 mm between the measuring planes. If necessary, to obtain an arbitrary size, not provided for by this measure of length, from suitable tiles by grinding the end measures of length to each other, you need to make up the intended size. Lapping must take place before the tiles stick together (that is, they must not fall apart).

What are they made of?

Today, end measures of length (plane parallel) are smelted from high alloy steel. They are also made of ceramics and hard alloys.

Steel KMD

Length measures made of steel, such as chromium, are well rubbed with the subject surfaces of the measuring racks and other measures. Their working surfaces are quite wear-resistant, which explains the increased service life.

Steel measures are necessarily subjected to hardening, and then artificial aging, which makes it possible to maintain the exact size for long-term use. The hardness of the working surface of Johanson's steel tiles is always at least 800 HV.

The disadvantages include special sensitivity to wear of work surfaces, scratches and possible corrosion. Before starting work with PCMD, protective lubricant is removed from them, and after the work is done, it is again applied. Measures of length (end plane parallel), GOST to which applies only to those made of steel, are susceptible to changes in temperature conditions, including the warmth of the operator’s hands.

KMD from the glory of hard alloys

Tiles smelted from tungsten carbide are ten times stronger than steel. Plus, they have perfect abrasion resistance. The hardness of the working surface of a hard alloy measure is almost two times greater (1400 HV) than the hardness of this surface in steel tiles. One drawback is the heavy weight. Therefore, it is impossible to assemble blocks for working with large sizes from carbide end measures.

Plane-parallel end measures of length (Johanson tiles) made of zirconium ceramics are considered the most resistant to scratches and wear of the working surface. Ceramics, as you know, is not afraid of corrosion, and, therefore, the moisture content of the hands of the operator does not affect the plates of zirconium ceramics (unlike carbide and steel). The length measures of this material have the greatest stability and the longest life, which makes it possible to increase the period between calibrations.

CMD from ceramics do not magnetize, do not require special anti-corrosion protection and do not attract dust. And also they are stable and able to keep the size long enough.

The analysis showed that steel and ceramic measures have a similar coefficient of thermal linear expansion. This indicator allows you to stack CMD blocks from ceramic and steel tiles, which makes measures from these materials completely interchangeable.

Glass KMD

They make end measures of length and of glass. They are used for checking lapping and checking flatness. And also for checking the flatness of precise work surfaces, for example, counter tables. Glass CMD with a diameter of 50 mm to 75, non-flatness less than 0.125 microns and a thickness of 15-20 mm are available.

How it works

The transfer and preservation of the exact size using plane-parallel end measures of length proceeds as follows.

On a special installation for measurements, the dimensions of the first discharge of exemplary end measures are checked.

End measures of length (plane-parallel), having certification of tiles of the highest accuracy, are stored exclusively in the laboratory rooms of Gosstandart. At industrial enterprises, depending on the requirements of the standards of accuracy for the manufactured products, tiles from the second to the fifth category are used. To convey the exact size is to periodically compare tiles of the first category and tiles of the second category. Then the latter - with tiles of the third category and further according to the scheme. Thus, in industrial enterprises all measuring devices are checked, from accurate to rough. The results of the verification are recorded in the passport of each device.

Lapping KMD

Lapping with regards to end measures of length is the effect of adhesion of two tiles. Plane-end gauges of length are polished so that when they are combined, air residues are removed and only atmospheric pressure affects them. The surface tension of the remaining droplets of liquid to flush the lubricant and the interaction between the molecules of the material from which the tiles are made increase the compressive strength.

If the plane-parallel end measures of length are polished, then they will be perfectly rubbed. This ability of tile measures of length is considered a mandatory requirement. For the loss of this quality means wear of the surface of the measure.

Essential Accessories

To collect the tiles in the CMD blocks and fix them in order to ensure ease of use, use a set of accessories for plane-parallel end measures of length. It is used quite widely. Accessories, for example, are needed for checking or sizing various measuring devices. It can be micrometric and indicator calipers, gauges, etc.

The kit necessarily includes side panels of different sizes, which makes it possible to carry out both internal and external measurements. This is especially important when producing high precision products in small batches. In this case, the accessories must be set to the maximum size of the manufactured product and to the minimum. That is, they are used as a two-sided caliber with a through side and an impassable one.

For marking work, an additional marking kit is used, to which holders are attached for particularly accurate measurements.

Also included in the kit are: ties, lateral plates are parallel and radiused, a trihedral ruler, a central and mark side, base, crackers and probes. The latter are necessary in order to determine the size of the gap between the ground surfaces. Probes are steel plates with a minimum size of 0.02 mm and a maximum of 1.0 mm. Their gradation is through 0.01 mm and 0.05 mm.

To use the dipstick to determine the amount of clearance, you need to place it between the surfaces. The probe should move with little effort and in no case should it sink and move freely. By the sum of the thickness of the probes, they fully enter the gap, and its value is determined.

Calibration and verification of CMD

Plane-end gauges of length are very important in the hierarchical chain of the transfer of size from the length sample (meter): they are a stable material carrier of the size constant.

The transfer of the reference meter, the basis of which is the light wavelength, to the reference end measures of the length takes place using deep interference measurements. Thus, we obtain a standard measure of length related to class K. Further, according to the verification scheme, it is transferred to other measures.

In accordance with the main purpose of the CMD (ensuring the uniformity of measurements and the transfer of dimensions of the standard length), calibration schemes have been developed. For the same purposes, measures of length of varying degrees of accuracy are issued for grades and classes. Verification of length measures (end, plane-parallel) is carried out with special instruments.

The very first of them was a specially invented micrometer. He was distinguished by increased accuracy. Years passed, devices improved. Today they produce the highest accuracy results and are no longer a rarity. Many laboratories have calibration instruments. In addition, KMD can be easily checked with incremental and inductive photoelectric comparators, which are freely available. And the methods of measurements on these devices have long been worked out. The advantage of this method is the simplification of the verification scheme of length measures. A certain disadvantage is the high cost of the devices and the high requirements for the qualifications of the specialist working with them. And the error. It is so small that on other devices the measurement results are difficult to double-check.

Basic verification methods

There are four verification methods:

- Indirect measurements of a given value.

- Direct measurements of a given value.

- Comparison with a comparator.

- Direct comparison with the standard.