In the processes of obtaining high-strength steels, an important role is played by alloying operations and modifications of the base composition. The basis of such procedures is the technique of adding metallic impurities of different properties, but gas-air regulation is of no small importance. It is precisely this technological operation that the operation of the oxygen converter is oriented to, which is widely used in metallurgy in the production of steel alloys in large volumes.

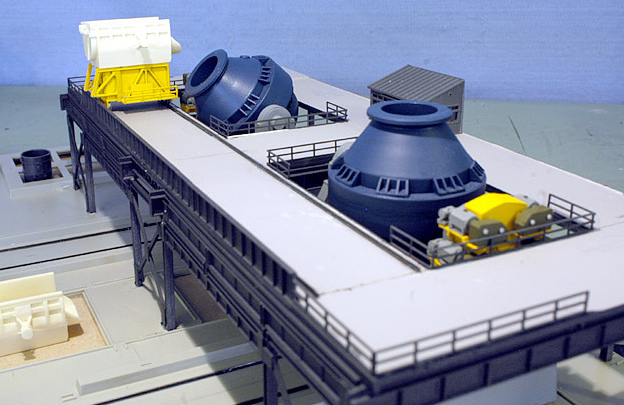

Converter design

The equipment is a pear-shaped vessel provided with an internal lining and a tap hole for the release of smelting products. In the upper part of the structure there is a hole with a neck for feeding tuyeres, scrap, molten iron, alloying mixtures and gas removal. The tonnage varies from 50 to 400 tons. As materials for the manufacture of the structure, sheet or welded steel with an average thickness of about 50-70 mm is used. A typical device of an oxygen converter provides for the possibility of detaching the bottom - these are modifications with bottom purging with gas-air mixtures. Among the auxiliary and functional elements of the unit, one can distinguish an electric motor, pipeline infrastructure for circulating oxygen flows, thrust bearings, a damper platform and a support frame for mounting the structure.

Support rings and trunnion

The converter is located on roller bearings, which are fixed on the bed. The design may be stationary, but this is rare. Usually, at the design stages, the possibility of transporting or moving the unit in certain conditions is determined. It is for these functions that the equipment in the form of support rings and trunnions is responsible. A group of bearings provides the possibility of torsion of equipment around the axis of the pins. Previous models of converters assumed the combination of supporting equipment and the case of melting equipment, but due to the influence of high temperatures and deformation of auxiliary materials, this design solution was replaced by a more complex, but reliable and durable scheme for the interaction of the functional unit and capacity.

The modern oxygen converter, in particular, is provided with a separate support ring, into the structure of which the trunnions and the fixed casing are also introduced. The technological gap between the casing and the support base prevents negative temperature effects on the sensitive elements of suspensions and mobile mechanisms. Directly the fixing system of the converter is realized due to the stops. The support ring itself is a carrier device formed by two half rings and trunnion plates fixed in the docking nodes.

Swivel mechanism

The electric drive allows the converter to rotate 360 °. The average rotation speed is 0.1-1 m / min. By itself, this function is not always required - depending on the organization of technological operations during the work process. For example, a turn may be required to orient the neck directly to the point of scrap supply, cast iron casting, steel drain, etc. The functionality of the rotary mechanism may be different. There are both one-way and two-way systems. As a rule, oxygen converters with a carrying capacity of up to 200 tons require turning in only one direction. This is due to the fact that in such structures less torque is required when the neck is tilted. To exclude the consumption of excess energy during the operation of heavy equipment, it is provided with a two-way turning mechanism, which compensates for the cost of manipulating the neck. The structure of the torsion system includes a gearbox, an electric motor and a spindle. This is the traditional layout of a stationary drive mounted on a concrete screed. More technological hinged mechanisms are fixed on the trunnion and are driven by a driven gear with a bearing system, which are also activated by electric motors through a system of shafts.

Converter Dimensions

During the design process, the design parameters should be calculated based on the approximate amount of purge without taking into account the melt emission. In recent years, units have been developed that accept materials in the amount of 1 to 0.85 m3 / t. The neck slope is also calculated, the angle of which is on average from 20 ° to 35 °. However, the practice of operating such structures shows that exceeding an inclination of 26 ° affects the quality of the lining. In depth, the dimensions of the converter are 1-2 m, but as the loading capacity increases, the height of the structure can increase. Conventional converters with a depth of 1 m can take a load of not more than 50 tons. As for the diameter, on average it varies from 4 to 7 m. The neck thickness is 2-2.5 m.

Oxygen Converter Lining

Mandatory technological procedure, during which the internal walls of the converter are provided with a protective layer. It should be borne in mind that, unlike most metallurgical furnaces, this design is subjected to much higher thermal loads, which also determines the features of the lining. This is a procedure involving the laying of two protective layers - functional and reinforcing. Directly adjacent to the surface of the casing is a layer of protective reinforcement 100-250 mm thick. Its task is to reduce heat loss and prevent burnout of the upper layer. The material used is magnesite or magnesite-chromite brick, which can serve for years without updating.

The upper working layer has a thickness of the order of 500-700 mm and is replaced quite often as it wears. At this stage, the oxygen converter is treated with non-calcined sand or tar knitted refractory compounds. The base material for this lining layer is dolomite with magnesite additives. A standard load calculation is made based on a temperature effect of about 100-500 ° C.

Shotcrete lining

Under aggressive thermal and chemical influences, the internal surfaces of the converter design quickly lose their quality - again, this applies to the external wear of the working layer of thermal protection. As a repair operation, shotcrete lining is used. This is a hot reduction technology in which a refractory composition is laid using special equipment. It is applied not in a continuous manner, but pointwise on heavily worn sections of the base lining. The procedure is performed on special shotcrete machines, which supply a water-cooled lance with a mass of coke dust and magnesite powder to the damaged area.

Smelting Technologies

Traditionally, there are two approaches to the implementation of oxygen-converter melting - Bessemer and Thomas. However, modern techniques differ from them in the low nitrogen content in the furnace, which improves the quality of the work process. The technology is carried out in the following stages:

- Loading scrap. About 25-27% of the total mass of the charge is loaded into an inclined converter by means of scoops.

- Pouring cast iron or steel alloy. Liquid metal at a temperature of up to 1450 ° C is poured into a tilted converter with ladles. The operation lasts no more than 3 minutes.

- Purge. In this part, steelmaking technology in oxygen converters allows for different approaches in terms of supplying a gas-air mixture. The flow can be directed from above, from below, by bottom and combined methods, depending on the type of equipment design.

- Receiving samples. Temperature measurement is performed, unnecessary impurities are removed, composition analysis is expected. If its results comply with design requirements, smelting is produced, and if not, adjustments are made.

Pros and Cons of Technology

The method is appreciated for its high productivity, simple oxygen supply schemes, structural reliability and relatively low costs for the overall organization of the process. As for the shortcomings, these, in particular, include restrictions in terms of adding sludge and recyclables. The same scrap metal with other inclusions can be no more than 10%, and this does not allow to modify the smelting structure to the necessary degree. Also, when blowing, a large amount of useful iron is consumed.

Technology application

The combination of pluses and minuses in the end determined the nature of the use of converters. In particular, metallurgical plants produce low-alloy, carbon and alloy steel of high quality, sufficient for the use of the material in heavy industry and construction. The production of steels in an oxygen converter occurs with alloying and improvement of individual properties, which expands the scope of application of the final product. Pipes, wire, rails, hardware, hardware, etc. are made from the raw materials obtained. The technology is also widely used in non-ferrous metallurgy, where blister copper is obtained with sufficient blowing.

Conclusion

Smelting in converter plants is considered obsolete equipment, but it continues to be used for reasons of the optimal combination of productivity and financial costs for the process. To a considerable degree of the demand for technology, the structural advantages of the equipment used contribute. The same possibility of direct loading of scrap metal, charge, sludge and other waste, albeit to a limited extent, expands the possibilities for alloy modification. Another thing is that for the full operation of large-sized converters with turning capabilities, the organization of the corresponding premises at the enterprise is required. Therefore, smelting with oxygen purging in large volumes is predominantly by large companies.