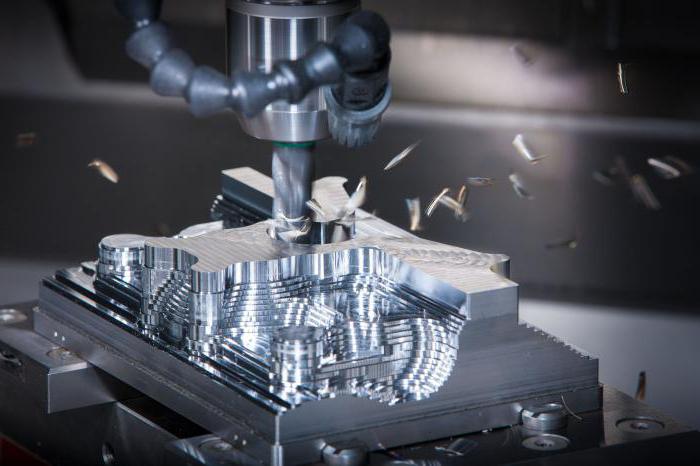

Milling is far from the easiest operation for processing metals and other materials, which is not always known in detail to the average person. The fact is that this process requires a special device called a mill - it can be found at many enterprises, factories, and factories. How is this process going? In this case, a cutting tool and a workpiece are involved. The cutting tool is the mill itself - it performs rotational movements, in contrast to the workpiece itself, which with the help of the machine makes translational movements towards the mill. The result is a type of processing that would be difficult to repeat using any other tool. However, this article will not consider surface information - this material is designed for those who are already more or less familiar with the milling process. The main and main topic here will be the cutting mode, that is, it will calculate and determine how the mill should function and what nozzle to use for specific types of metal of different hardness. To make it easier for you to understand the data that will be provided later, you should immediately find out which concepts will be used here.

All you need to know

So, in each paragraph it will be indicated which particular material is examined, as well as its hardness according to the Brinnel method - the most famous and widespread of all methods for determining the hardness of bodies. They are measured in HB, that is, Brinnel hardness units. Next, the cutting speed will be determined , which is indicated in meters per minute (m / min). Here you should pay special attention to the fact that these are not cutter revolutions, namely, a completely different parameter. This parameter will be considered in several examples - if the material processed by the mill has no additional coating, and also if the mill has different types of TI-NAMITE coatings. And, of course, another very important milling parameter will be described - this is the feed per tooth. For people far from this area, this parameter may seem rather unusual, but if you carefully study its details, then everything will become quite simple. So, this parameter is measured in millimeters per tooth and determines how many millimeters the workpiece moves while the cutter rotates by one tooth. From this feed, you can also calculate others - for example, reverse and minute, but it is the feed to the tooth that is the key factor. And it will also depend on the diameter of the tool used. Well, you got all the basic data - now it's time to find out which cutting mode to use when milling in which particular case.

General steel

So, the first material that is considered in this article is steel of general application. What cutting mode to use for such a material? First of all, you need to determine the hardness of the material. If the hardness of the steel is less than 150 Brinnell units, then it is necessary to set the speed from 150 to 210 meters per minute, depending on the coating. 150, respectively, in the complete absence of coverage, and 210 in the presence of the most effective coating TI-NAMITE-A. As for the feed to the tooth, it all depends, as mentioned above, on the diameter of the tool. If its diameter is less than three millimeters, then the feed per tooth will be from 0.012 to 0.018 millimeters, with a diameter increase to 5 mm, the feed increases to 0.024 mm, if the diameter increases to 9 mm, then the feed increases to 0.050 mm, with a diameter up to 14 the feed can increase to 0.080 mm, but with a maximum diameter of 25 millimeters, the feed per tooth will be 0.18 mm. These data allow you to choose the correct cutting mode. But do not forget that there are more solid types of steel for general use. With a hardness of less than 190 Brinnell units, the speed should be from 120 to 165 meters per minute, and with a hardness of less than 240 Brinnell units, from 90 to 125 meters per minute. Naturally, the feed per tooth changes. It becomes smaller and in the first case it can be from 0.01 to 0.1 millimeters per tooth, while in the second case it can be from 0.008 to 0.08 millimeters per tooth. Naturally, this is not the only material used in milling, so you should pay attention to other metals.

Cemented steels

The cutting conditions during the processing of cemented steels will depend on the hardness of the material. If it is less than 235 Brinnell units, then the cutting speed will be appropriate - from 100 to 140 meters per minute. With hardness less than 285NV, the indicator drops - from 80 to 110 meters per minute. But at the same time, do not forget about the feed to the tooth. In principle, you can not talk a lot about it, because it does not differ from what you already saw in the previous paragraph. In the first case, it will have the same intervals as in the processing of steel of general use with a hardness of less than 190NV, and in the second it will be the same as with the processing of steel of general use with a hardness of less than 240NV. But it cannot be said that the feed to the tooth will be identical, because to the maximum diameter of the tool in the first case, the feed is not 0.1, as in the previous example, but 0.15. That is why the calculation of cutting conditions is such a difficult task, which is best done in accordance with all standards and in accordance with strict requirements.

Nitrided Steels

The calculation of the cutting conditions when processing nitrided steels is no different from the previous cases - only in this case the materials are a little harder than the past, so you should not be surprised that the cutting speed here will be from 90 to 125 meters per minute with less hard steel and from 70 to 95 meters per minute with harder material. As for the feed to the tooth, in the first case there is a completely standard step increment - from 0.008 to 0.08 millimeters, but if the metal has a large number of Brinnell hardness units, this will mean that its feed will decrease, and noticeably. With a minimum diameter of the tool, it will be 0.006 mm, and with a maximum diameter of 0.06 mm. At the moment, this is the lowest feed per tooth, considered in this article. Calculation of cutting conditions for this information is usually carried out according to the standard formula, which will be discussed at the end of the article.

Medium carbon steels

Mild steels are very common, and most importantly, there are several different levels of their hardness. And, of course, each of them will have its own cutting speed. For example, the first two types of steel have the same indicator, if the cutter has no coating - 80 meters per minute. But with maximum coverage, the first type increases the speed to 110 meters per second, and the second only up to 85 meters per second. But there are two more types, the first with a hardness of less than 340 HB and the second with less than 385 HB. Accordingly, in the first, the cutting parameter will be from 50 to 70 m / min, and in the second - from 35 to 50 m / min. Compared to the types that you saw earlier, this is a pretty low speed. Accordingly, for these types of steel the feed to the tooth is not too high - it’s worth separately highlighting the last hardness steel, which has an incredibly small feed with a minimum diameter of the tool, only 0.005 millimeters. It should be noted right away that milling is considered here, and not cutting modes when turning. As mentioned above, a formula is used for the calculation, which you will familiarize yourself with above. The cutting modes during turning are calculated using a slightly different formula, so you should not try to apply one calculation to all types of work.

Tool steels

In terms of hardness, tool steels are divided into even more types than medium-carbon ones, therefore, the cutting conditions during milling of tool steel can be numerous. In short, it is precisely about this steel that there are five types of hardness: less than 230NV, less than 285NV, less than 340NV, less than 395NV and more than 395NV. Each of them has its own cutting speed: from 90 to 125 m / min, from 70 to 95 m / min, from 60 to 85 m / min, from 45 to 65 m / min and from 30 to 40 m / min, respectively. As a matter of fact, by the name of this data you will be already halfway to fill in all the missing gaps in the calculation of the formula, with the help of which the cutting modes during milling are determined. In order for all variables to be replaced by numbers in the formula, you also need to know the diameter of the tool (and the data received from it on the feed to the tooth).

How to choose a mode?

The choice of cutting modes is quite simple - each cutter has a switch that allows you to control the speed of rotation of the cutting tool. With this small switch, you can set the approximate value of revolutions per minute, and then your machine will work at this level. Actually, this is the cutting mode, but such a simple process has a large number of calculations, which will be discussed later. The fact is that determining the rotation speed of the cutting tool of the cutter should be as accurate as possible, and rarely when you have enough time and material to select the cutting conditions of the metal at random. It is for this that there is a theory that must be used before practical application.

Cutting speed formula

It is very important to comply with the standards of cutting conditions, since the point here is not only that you will spend a lot of time, but even worse - a lot of material to select the desired mode blindly. It may also be unsafe. Therefore, it is best to be guided by theoretical knowledge in the first place. So, now you will find out the formula by which the mode for a particular metal is calculated. How it can be put into practice will be described below. The formula itself assumes that the speed, expressed in meters per minute, is multiplied by a conversion factor of 1000, and the result is divided by the product of the number pi, times the diameter of the cutter. These are all the elements of the cutting mode you need to calculate the speed of rotation of the cutter.

Simplified formula

It makes no sense to carry out two multiplications when you know that the number pi is a digit without any variables. Initially, it is customary to reduce 1000 and 3.14 to get 318. 318 is multiplied by speed, and then the result is divided by the diameter of the cutter. That's all, this formula is already much simpler than the previous one, and it is with its help that the cutting mode is most often determined.

Payment

In such material it is impossible to do without an example. Well, for example, you can take general-purpose steel with a hardness of less than 150NV and a mill with a TI-NAMITE coating and a diameter of 10 millimeters. So, first you need to check the data that were described in the article above - with these indicators, the cutting speed will be 175 m / min, so you need to multiply 318 by 175, it turns out 55650. Now you need to divide it by the diameter of the cutter, that is 10 - it turns out 5565. This is precisely the meaning sought. Now you need to set it on your machine, and if it is impossible to set such a value specifically, it is recommended to take a little less.

Foreign instrument catalog

If you use a domestic cutter, then most likely you can easily find the necessary data to determine the cutting mode. If you have a foreign sample, then you may have certain problems. That is why when buying a foreign milling machine it is extremely necessary to ask for a catalog with all the necessary explanations, which you can then use as a theoretical basis when working with the machine.

Special Graphics

The real salvations are graphs that are compiled for faster and more convenient determination of the cutting mode. What is such a schedule? This is a set of straight lines of different colors that are between two axes - one of them shows the speed, that is, the value that you know, because you know what material you are processing, and the second is the number of revolutions per minute that your cutter will make , that is, simply put, the mode of its operation. Why are the lines different in color? If you have not forgotten, then the number of mill revolutions per minute cannot be calculated only by the cutting speed - you also need the diameter of the tool, and each color is responsible for its diameter.

How to use the schedule?

All that is required of you is to find the diameter of your instrument in the table and select the straight line of the desired color on the chart. Then you need to determine the speed and draw a straight line from the y axis, that is, the axis on which the values of this parameter are indicated. From the intersection of your line with the straight line of your chosen color, you must draw a straight line to the x axis to find out the exact number of revolutions per minute.