The history of the creation of paper dates back more than one thousand years, and to this it remains the most common means of transmitting information in a graphic or symbolic way. But it also found its application in everyday life, as a packaging material, in interior design and for hygienic purposes.

With its help, graphic images were transmitted through the drawings. If in the past it could be the first sketchy sketches of objects and phenomena of people around us, now photos with high detail are printed on paper, as closely as possible reflecting the surrounding reality.

But if we talk about writing, then it arose much earlier than paper came into being. There have been many alternatives to this material in the past. Some of them, to be honest, were much more durable. But paper also had its advantages, which allowed it to gain such widespread distribution. This process was extremely heterogeneous. If in China they knew about paper before our era, then European civilizations joined it only in the Middle Ages.

Paper making has evolved with the advent of new technologies. Moreover, this was due both to the requirements of the new printing technology, and to the methods for its production. If earlier it was required to process fabrics for its production, then with the advent of the period of the industrial revolution and the discovery of pulp, everything changed.

The importance of paper in the development of society cannot be underestimated - through fiction and scientific publications. Accessibility of books played a huge role in education, which brought technological progress closer.

At present, the role of paper is decreasing, but even with the advent of electronic document management, all significant papers have their material embodiment, whether it is banknotes or any kind of identification.

What is paper for?

In the modern world, we use paper products in our daily routine, sometimes without even thinking about it. We meet her at home and at work. It is used for advertising, checks are printed on it for purchased goods, and, in the end, we often pay for purchases with paper notes.

The history of paper originally intended to be used to preserve and transmit knowledge. Now this role is given to books, brochures, newspapers and other printed information products.

For decoration purposes, paper is used for the production of wall-paper, print photographs and as a basis for paintings and prints.

As a material for packaging, paper cardboard is used. Huge boxes for transporting goods, as well as small bags with juice or milk are made from it.

Paper with watermarks and other degrees of protection is used for important documents that are provided in a single copy: passports, registration certificates, licenses, etc. Paper production using similar technologies is also used for the manufacture of banknotes.

Paper in the form of a tape is used to measure the performance of measuring instruments in medicine and science. This is especially true for equipment that is not designed to work with digital media.

A look into the past

Ancient images of animals and hunting for them made by primitive tribes can be found on the walls of caves. The first Egyptian script that reached us was also engraved on stone slabs. They were heavy, and working with them required a certain skill from the master. With the development of metallurgy, metal plates began to be used, but each time the text had to be applied to the casting form, which was also inconvenient.

In Mesopotamia, they came up with more convenient material for recording. The Sumerians used clay tablets for their cuneiform writing. It was quite a convenient way: it is convenient to write on soft clay, dried tablets were relatively light. But they were fragile enough.

But the ancient Egyptians in the third millennium BC came up with papyrus, which can rightfully be considered the precursor of paper. It was made from the plant of the same name, growing on the banks of the Nile. For direct production, the inner fibrous part was used, which was separated from the stem. Separated layers of fiber were applied transversely relative to each other and placed under a press. Both plant juice itself and muddy Nile water, rich in silt deposits and mud, and softened bread crumb acted as binding material. The resulting sheets were glued together in a scroll. It was a good way to store records, the papyrus was lightweight, easy to transport, and it was possible to record volumetric texts on it.

Paper birth

The creation of the first paper from Chinese silk occurred presumably before our era. But its exact place of origin and time of origin is unknown. During archaeological excavations, scraps of paper were found in the burial site, which belonged to the era preceding the rule of the Han Dynasty. But the first paper, like papyrus, was very expensive. Therefore, at that time, wooden tablets were more common, on which the text was burned with a heated pen tip.

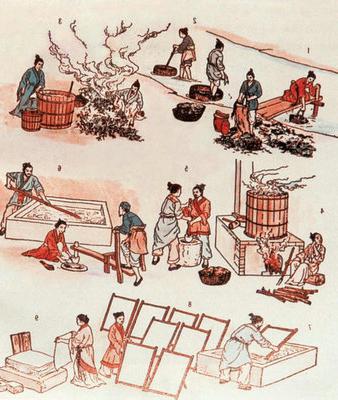

It is reliably known that in 105, the adviser to the emperor Tsai Lun was awarded the title of minister and other honors for his contribution to the improvement of papermaking technology. Only culled silkworm cocoons or scraps of fabric obtained from mulberry bast were used for its production. They were divided into small pieces, and then crushed in a mortar almost to the state of powder. The resulting mass was mixed with pure water in a homogeneous slurry, which was then laid out in a forming bamboo sieve. The frames on its sides set the size of the sheet, and the holes promoted ventilation, air flow and, as a result, quick drying. To smooth the mesh pattern, paper was placed between two polished stone surfaces. Thus, it turned out to be smooth and thin at the same time.

After the invention of this method, the further paper making process improved quite quickly. In the production technology, special binder compositions based on starch and glue of natural origin began to be used, which made the paper more durable. And the basis was not only silk fiber, but also other cotton and linen fabrics, as well as hemp thread, which was usually used to make ropes.

Alternative to paper

Along with the teachings of Buddhism from China, books were distributed to Korea and Japan that were in close contact with him, respectively, and they took over the experience in paper production. Also, the manufacture of paper and the technology of its creation mastered the neighboring countries of Central Asia and the Middle East. But paper got to the European continent only after the Arabs conquered Spain.

Naturally, before its distribution, alternative materials were used for recording texts. Since ancient times, expensive papyrus was replaced with parchment and wax tablets.

The latter were wooden plates on which wax was applied in a thin layer. The writing tool was a solid metal stick, one side of which was pointed for writing letters, and the other, flat, scraped off, after which the text could be rewritten. This method was widely used for teaching writing and creating temporary records until the Middle Ages.

For more long-term use, parchment from animal skins of special dressing was used. In the leather industry, the skin of sheep or goats was soaked in liquor, softened and pressed. The main advantage of parchment was that it allowed you to write on it from two sides. Therefore, the first European books were made from it.

In ancient Russia, birch bark was used. But, unfortunately, only a small number of letters written on it have survived to this day.

The forerunners of modern paper

The history of the creation of paper in its modern form did not exist until the 18th century. The technology of its production differed depending on the material used, whether it be rags or wood.

Attempts to use wood fibers directly did not give a significant result. Although in China, bamboo was successfully used at the end of the first millennium AD.

The main raw material for book paper was old waste paper and worn canvas clothing. Here on the newspaper came cheaper material, for example, straw. It got to the point that there was a shortage of them, some countries even imposed a ban on the export of rags. And in America, a situation arose when book printers sold books only to those who brought them raw materials for processing. Under the influence of such rush demand, prices were rising, which led to the emergence of black markets.

The crushed raw materials were placed in a large tub with water, after which they were thoroughly mixed to a state of suspension, when the particles were placed in the mixture more or less uniformly. Initially, manual labor was used, and the work of the scribe was very respected. He made sure that the semi-finished product reached the required state, after which he spread the gruel on a special sieve.

A little later, mills appeared , the water wheel of which set the shaft in motion. Its mechanical energy was transferred to the grinding of raw materials for paper pulp. Each mill used an imprint or a watermark to indicate the exclusivity of its production. On the metal mesh scoop some sign was sewn with wire, which appeared on the paper pulp after drying.

From Spain, paper business migrated to other European countries. Italian craftsmen have learned to experiment with chemicals. White paper was obtained by bleaching with chlorine, and the use of organic glue from cooked animal bones made it possible not to absorb ink.

In the pre-Petrine era, our country bought paper from France and Italy, and only in 1714 the first water mill was laid to mechanize the production process. But, despite the slight lag of Europe from Asia, it was there that they came up with a way to create stamped paper with watermarks, which neither the Chinese nor the Arabs had.

Pulp and the industrial revolution

The history of the paper has undergone great changes after studying the composition of wood and the appearance of roll paper without a trace of mesh.

The discovery of cellulose in 1719 belongs to the French chemist Rene Reaumur. It was he who first proposed its use in the production process. Cellulose is a dense layer of polymer glucose molecules that create a protective barrier in the cell membrane. The process of its isolation from wood or grass fiber occurs under the influence of reagents that break down the less stable substances that make up the cells. The higher the cellulose content in the plant, the more dense paper will be obtained from it. But only with the advent of the paper machine did this raw material become widely used.

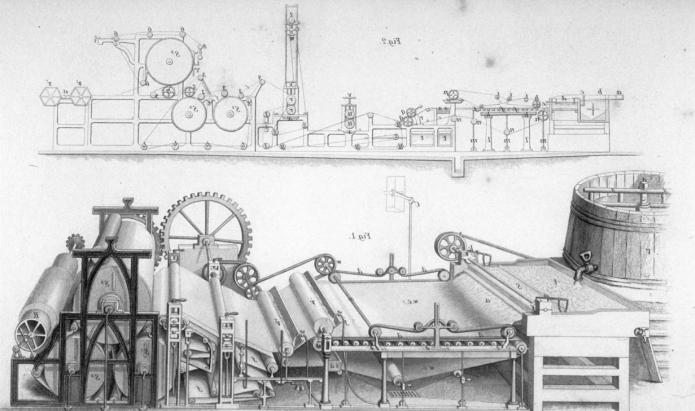

The first high-quality paper machine without traces of mesh appeared in England. But while it was still made from waste linen rags, which were crushed in a special apparatus called "roll". The paper pulp was laid out not on a metal sieve, but on a special fabric of dense weaving. The resulting sheets were called "whatman" in honor of the owner of the factory, they acquired a characteristic roughness and velvety. This allowed the emergence of watercolor techniques for painting, moving the leading position of the canvas and oil paints.

But the demand for paper was huge. To increase its number, paper machines arose. Rolls were crushed by sawdust, waste from woodworking industries, which were then placed in an acidic or alkaline environment, where the splitting of wood fibers took place and cellulose was released. The resulting mass of semi-finished paper swelled, absorbing water well. After that, it could conditionally be considered raw paper. But to give shape, the pulp was rolled between two oppositely rotating shafts with a copper mesh. Thus, paper appeared in rolls. But simply the paper was obtained after cutting it with special knives. This process allowed us to create paper of a certain size and density in huge quantities in an almost automatic way.

Depending on its purpose, special additives were introduced into the composition of the paper pulp. For example, special photo paper was processed by the light-sensitive components, which is why the development of photographs was carried out in a room with red lighting. And dyes gave the sheets the required shades.

The role of paper in the development of mankind

For a long time paper production remained a trade secret of a limited circle of owners. The manufacturing process was extremely time consuming. The history of paper, as well as its use, was the privilege of representatives of the wealthy class who corresponded, read books, and raised their level of education.

The more accessible paper media became, the faster the pace of gaining new information by a wide range of people. For example, Marco Polo wrote a book about his travels, thousands of people read it, and their picture of the world expanded. Darwin described his conclusions about the origin of the species that came to him in his youth when he went on an expedition on the Beagle ship.

Thus, the level of education of society increased, which indirectly brought closer the current level of development. Typography was developing, handwriting was no longer needed, typewriters later appeared, and printers appeared in the computer age.

Modern types of paper

The history of creating paper for drawing has not undergone major changes. For creativity, rough paper of manual and industrial production is still in demand. When choosing it, they first of all take into account what is the absorbing ability, how the fibers were ground. The larger they are, the more paper will be scuffed when scraping.

Office light paper is primarily intended for laser or cartridge printer printing. Copying is carried out using a similar technology. But earlier, carbon paper was used for these purposes, one side of which is covered with a thin layer of coloring pigment. Now it is used only for the simultaneous duplication of the handwritten text of references and receipts.

Printing digital images has greatly influenced such a thing as paper. Photos printed on it have both a glossy surface and a matte finish. Based on whether the laser or inkjet printer, choose different types of paper by density. Also, the quality of the paper must be considered when using certain inks refilled in the cartridge.

Disposable paper handkerchiefs are more practical than their fabric counterparts. Roll toilet paper has been produced for more than a century. And in America, there is a known case when, instead of a roll, volumes of cheap poetry were produced from soft paper for hygienic purposes. This led some to bewilderment, but the manufacturer initially intended to combine these two processes.

Corrugated cardboard paper is made from relatively cheap raw materials - straw. Strength is achieved due to the folded accordion layer located between two sheets of cardboard. Thus, the pressure exerted by the weight of objects is dispersed due to the elastic layer that is resistant to deformation. But such cardboard has visible inclusions of fibers, due to the porous texture of the box from it are deformed under the influence of water, although in all other cases they are very convenient for transportation.

Tetra Pak technology is used for packaging food products. The inner layer of the bag in contact with the wet environment is covered with a thin layer of food foil. And the outer one is a bright cardboard with a glossy surface, on which the name, composition and so on are applied.

Prospects

Paper media are dying out. Although reading is still very popular, paper books, magazines and newspapers are bought less and less. They are gradually being replaced by electronic counterparts.

The readings of measuring instruments are increasingly stored in electronic form. Yes, and documents are easier to create in digital form, and then confirm their authenticity using certificates.

: , , ....

. , , , , , .

, , . . , , , .

, .