The metalworking industry at this stage of development is capable of solving the complex tasks of cutting and drilling workpieces of varying degrees of hardness. This became possible thanks to the development of fundamentally new ways of influencing the material, among which a wide group of electromechanical methods. One of the most effective technologies of this type is ultrasonic processing (RCD), based on the principles of electro-acoustic radiation.

Principles of dimensional RCD

In dimensional processing, conventional mechanical carvers and abrasives act as a direct tool of influence. The key difference between this method is the source of energy that powers the tool. In this capacity, the ultrasonic current generator operating at frequencies of 16–30 kHz acts precisely. It provokes vibrations of the same abrasive grains at the ultrasonic frequency, which ensures a characteristic processing quality. Moreover, a variety of types of mechanical impact should be noted. This is not only the usual cutting and grinding elements, but also the deformation of the structure while maintaining its volume. Moreover, ultrasonic dimensional processing provides the minimum sample of particles of the workpiece, even when cutting. Grains that affect the material point hollow out microparticles that do not affect the design of the product. In fact, the destruction of the structure by sampling does not occur, however, uncontrolled propagation of cracks can take place.

Differences from plasma processing technology

In terms of processing quality, the ultrasonic and plasma methods have many similarities, providing the possibility of high-precision cutting. But also between them there is a significant difference in the principle of work. So, if RCD involves an intensive impact on the abrasive powder from the miter tool with the energy support of an electric wave generator, then the plasma treatment method uses ionized gas charged with ions and electrons as a working medium. That is, ultrasonic and plasma processing technologies equally require the support of a sufficiently powerful energy generator. In the first case, this is an ultrasonic electric apparatus, and in the second, high-temperature gas or isothermal installations that can bring the temperature of the working medium to 16,000 ° C. An important component of plasma processing is the use of electrodes and plasma-forming substances, providing high power guided arc cutter.

Ultrasonic Processing Machines

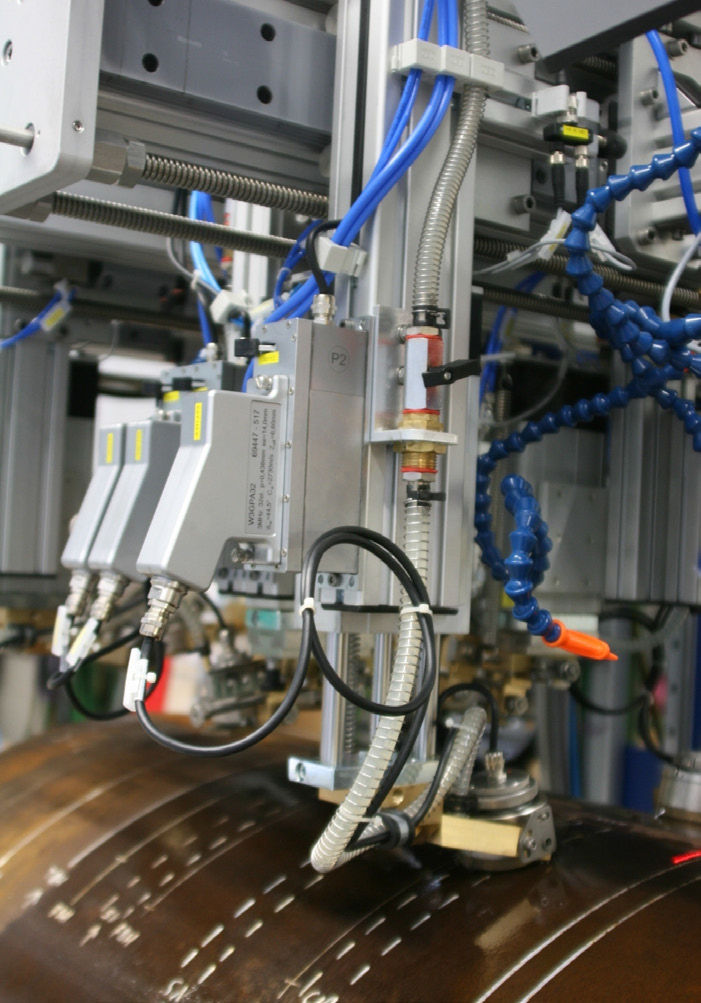

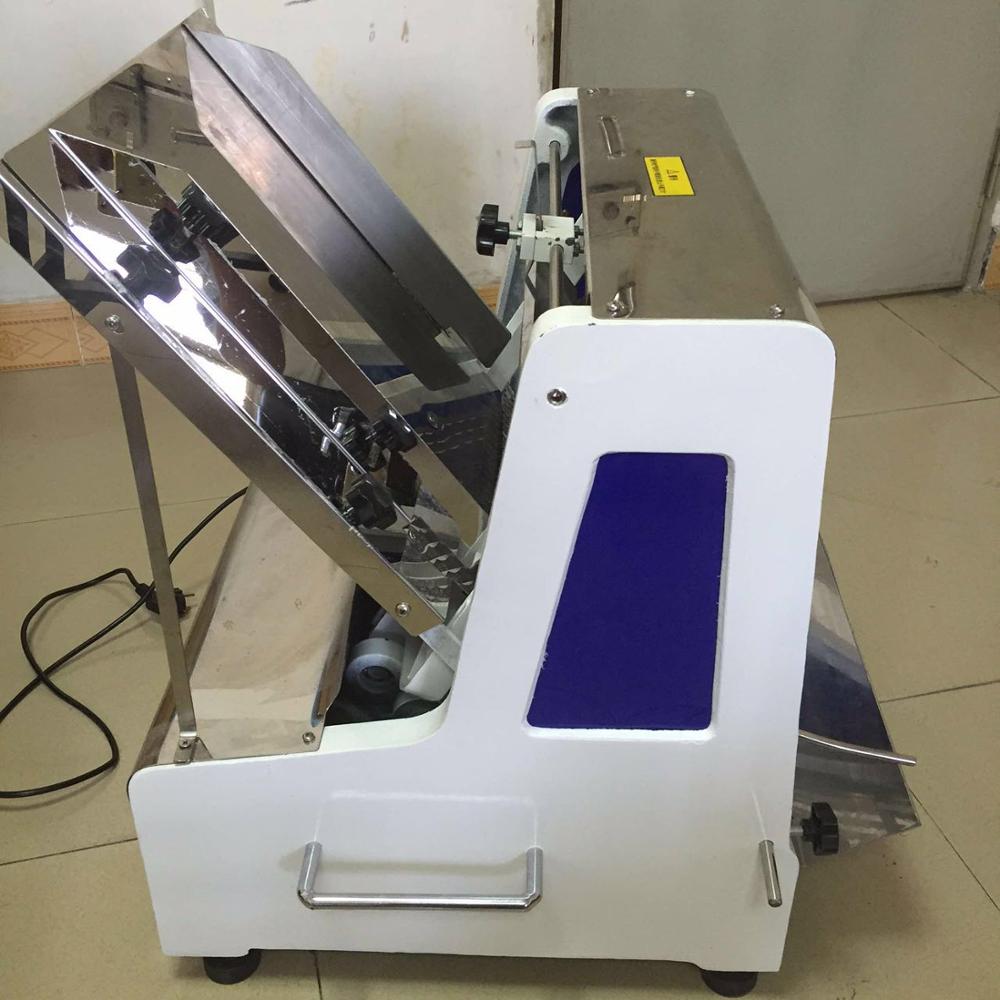

Now it is worthwhile to dwell in more detail on the equipment that is used in the implementation of RCDs. In large industries, for such purposes, machines are used that are provided with a generator set for generating alternating current of ultrasonic frequency. The generated current is sent to the winding of the magnetic transducer, which, in turn, creates an electromagnetic field for the working body of the installation. Ultrasonic processing begins with the fact that the punch of the machine begins to vibrate while in an electromagnetic field. The frequency of this vibration sets the generator based on the set parameters that are required in a particular case.

The punch is made of magnetostrictive material (an alloy of iron, nickel and cobalt), which can change in linear dimensions under the influence of a magnetic transducer. And at the final crucial stage, the punch acts on the abrasive powder through vibrations directed along the waveguide-condenser. Moreover, the scale and processing power may be different. The considered equipment performs industrial metalworking with the molding of massive structures, but there are also compact devices with a similar principle of operation, on which high-precision engraving is performed.

Technique of performing dimensional RCD

After installing the equipment and preparing the target material, the abrasive slurry is fed into the area of the operation — that is, into the space between the surface of the product and the oscillating end. By the way, silicon or boron carbides are usually used as the abrasive itself. On automated lines, water is used for powder delivery and cooling. Directly ultrasonic processing of metals consists of two operations:

- Impact introduction of abrasive particles into the intended surface of the workpiece, as a result of which a network of microcracks is formed and microparticles of the product are punctured.

- Circulation of abrasive material in the processing zone - used grains are replaced by flows of new particles.

An important condition for the effectiveness of the whole process is to maintain a high pace when performing both procedures until the end of the cycle. Otherwise, the processing parameters change and the accuracy of the abrasive direction decreases.

Process characteristics

Pre-set processing parameters that are optimal for a particular task. The configuration of the mechanical action and the properties of the workpiece material are taken into account. The average characteristics of ultrasonic processing can be represented as follows:

- The frequency range of the current generator is from 16 to 30 kHz.

- The oscillation amplitude of the punch or its working tool is the lower spectrum at the beginning of the operation is from 2 to 10 microns, and the upper level can reach 60 microns.

- The saturation of the abrasive slurry is from 20 to 100 thousand grains per 1 cm3.

- The diameter of the abrasive elements is from 50 to 200 microns.

Varying these indicators allows you to perform not only individual high-precision linear processing, but also accurately form complex grooves and cuts. In many ways, work with complex geometric shapes became possible due to the perfection of the characteristics of punches, which can affect the abrasive composition in different models with a thin superstructure.

Deburring by RCD

This operation is based on an increase in the cavitational and erosive activity of the acoustic field when introducing ultrafine particles from 1 μm into the abrasive stream. This size is comparable with the radius of the shock wave, which allows you to destroy the weak zones of the barbs. The workflow is organized in a special liquid medium with a glycerin mixture. As a container, special equipment is also used - a phytomixer, in a glass of which there are suspended abrasives and a workpiece. As soon as an acoustic wave is supplied to the working medium, the random movement of abrasive particles begins, which act on the surface of the workpiece. Small grains of silicon carbide and electrocorundum in a mixture of water and glycerol provide effective deburring up to 0.1 mm in size. That is, ultrasonic processing provides accurate and high-precision removal of microdefects that could remain even after traditional mechanical grinding. If we are talking about large burrs, then it makes sense to increase the intensity of the process by adding chemical elements like copper sulfate to the tank.

Cleaning parts using an RCD

On the surfaces of working metal billets, various kinds of coatings and contaminants may be present, which are not allowed to be removed by traditional abrasive stripping due to various reasons. In this case, the technology of cavitation ultrasonic treatment in a liquid medium is also used, but with a number of differences from the previous method:

- The frequency range will vary from 18 to 35 kHz.

- Organic solvents like freon and ethyl alcohol are used as the liquid medium.

- To maintain a stable cavitation process and reliable fixation of the workpiece, it is necessary to install a resonant mode of operation of the phytomixer, the liquid column in which will correspond to half the length of the ultrasonic wave.

Ultrasound-assisted diamond drilling

The method involves the use of a rotating diamond tool, which is driven by ultrasonic vibrations. The energy costs of the processing process exceed the amount of required resources with traditional methods of mechanical impact, reaching 2000 J / mm 3 . This power allows drilling with a diameter of up to 25 mm at a speed of 0.5 mm / min. Also, ultrasonic treatment of materials by drilling requires the use of coolant in large volumes up to 5 l / min. The fluid flows and is washed out from the surfaces of the tooling and the workpiece of fine powder formed during the destruction of the abrasive.

RCD monitoring

The technological process is under the control of the operator, which monitors the parameters of the vibrations. In particular, this refers to the amplitude of the oscillations, the speed of sound, and also the intensity of the current supply. Using this data, the working environment and the impact of abrasive material on the workpiece are controlled. This feature is especially important during ultrasonic processing of tools, when several modes of equipment operation can be used in one technological process. The most advanced control methods involve automatic means of changing processing parameters based on the readings of sensors that record the parameters of the product.

The benefits of ultrasound technology

The use of RCD technology gives a number of advantages, which manifest themselves to varying degrees depending on the specific method of its implementation:

- The productivity of the processing process increases several times.

- The wear of the tool used for the ultrasonic processing method is reduced by 8-10 times compared to conventional machining methods.

- When drilling, the processing parameters increase in depth and diameter.

- Improves the accuracy of mechanical stress.

Technology disadvantages

The widespread use of this method is still hampered by a number of disadvantages. They are mainly associated with the technological complexity of the organization of the process. In addition, ultrasonic processing of parts requires additional operations, including the delivery of abrasive material to the working area and the connection of equipment for water cooling. These factors can increase the cost of work. When servicing industrial processes, energy costs also increase. Additional resources are required not only to ensure the function of the main units, but also to operate the safety systems and current collectors that transmit electrical signals.

Conclusion

The introduction of ultrasonic abrasive technology into metalworking processes was due to limitations in the use of traditional methods of cutting, drilling, turning, etc. Unlike a conventional lathe, ultrasonic metal processing is able to effectively cope with materials of increased hardness. The application of this technology made it possible to carry out processing operations of hardened steel, titanium-carbide alloys, tungsten-containing products, etc. At the same time, high accuracy of mechanical impact with minimal damage to the structure located in the working area is guaranteed. But, as is the case with other innovative technologies such as plasma cutting, laser and hydroabrasive processing, there are still problems of economic and organizational nature when using such metal processing methods.