Coal, the extraction of which is carried out in mines underground, needs an additional processing process. Coal preparation is necessary because the raw materials mined underground have many unnecessary impurities.

General information

Why is the enrichment process so important? All due to the fact that the impurities present in this material will give a low combustion temperature if you start using them. Thus, it turns out that you have to burn a large amount of coal, which will give a low combustion temperature. The enrichment of coal is the purification of raw materials from all unnecessary substances that interfere with its combustion.

During this procedure, several goals are achieved. Firstly, mineral substances and impurities are removed, and secondly, the mined coal is divided into fractions according to grain size and grade. Only after passing through these procedures and checking the quality of the final product does coal enter the consumer.

Screening and wet dressing

The process of coal enrichment involves several stages. The first of them is screening, or the separation of raw materials into fractions according to size and grade. In order to carry out the initial processing, equipment such as a vibrating screen is used. This is a huge sieve. Most often, there are several pieces at the enrichment factory, and their main difference is the size of the cells. Getting on screens with different cells, coal is divided into several groups. If we talk about the classification of coal by size, then there is a generally accepted standard scheme that includes several types - seed, nut, etc.

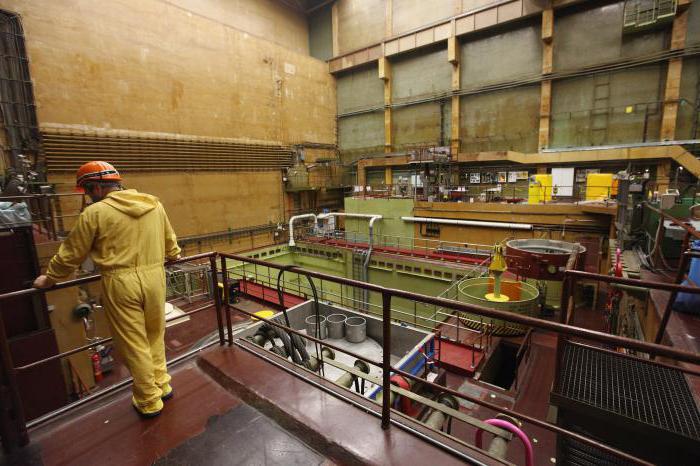

One of the most common types of coal processing is wet. This procedure is based on the principle of density separation. Since impurities have a lower indicator of this parameter, and coal - a larger one, their separation will occur in the aquatic environment. Machines in which this process is carried out are called jigging machines. This equipment belongs to gravity enrichment devices.

Products

The raw materials that are used to carry out these works are called nutrition. During the processing of stone raw materials, one can obtain such coal enrichment products as:

- Concentrate. This is the name of those processed products that have retained the maximum amount of combustible substances in their composition, and the content of rock components has been reduced to a minimum.

- Industrial product. This raw material is an intermediate product. The content of combustible substances in it did not reach its maximum value, but the amount of rock components did not increase too much. Such processed products are considered unprepared and need additional processing.

- Mixed, or waste. With this raw material, everything becomes clear from its name - the content of combustible components is minimal, and the breed - the maximum.

Coal preparation technology

There are several different processes at the processing plants , which are divided into groups depending on their technological purpose.

The first category is preparatory procedures. The main task at this stage is to reveal the components of the rock mass, divided into machine classes, etc. This stage includes such types of operations as screening and crushing. If we talk about the crushing process, then it is quite simple. The objective of this stage is to break up the existing pieces of rock to the required size. For this, external forces are used, that is, special equipment. Screening, as mentioned earlier, is the procedure for dividing pieces of rock into classes by size.

After completing the preparatory phase, you can proceed to the main one, the task of which is to divide the existing pieces of coal into concentrate, industrial product or mixed.

Currently, enrichment factories use such types of gravity enrichment as depositing, screw and counterflow separation, enrichment in heavy suspensions.

Some facilities use coal processing plants that perform flotation procedures. The essence of enrichment technology in this way is that the difference in the physical and chemical properties of coal and impurities is used.

Supporting processes

In addition to the main processes, several auxiliary processes are used at enrichment plants. These include dehydration or dedusting operations.

Naturally, the dehydration procedure is applicable only to those enrichment products that passed through gravity treatment. To accomplish this task, several different methods are used. Large pieces, more than 13 mm, are dehydrated on screens, elevators or in drainage bins. Crayons, however, the rock classes go through a centrifugation process, and in winter also thermal drying of the material.

Dust removal is the process of separating dust particles from coal whose size is less than 0.5 mm. To accomplish this task, two methods are used. Wet method - screens or hydrocyclones are used. The dry method involves air classifiers with various designs.

Coal beneficiation schemes

It is important to note here that there is no single scheme for enrichment. In each case, you have to make a choice from several available options. The decisive factors that influence the outcome are the properties of the ore itself, as well as its purpose.

For example, if we talk about the depth of enrichment, then there are several of the following technological schemes:

- The first method involves enrichment of only the largest parts, the size of which exceeds 25 (13) mm. Subsequent shipment of the rock is carried out either jointly, that is, both the concentrate and the waste are shipped together, or separately.

- The second method is enrichment of only the middle class rock with a size of more than 6 (3) mm. The separation of the obtained products can also occur jointly or separately.

There is also a division into several schemes, depending on the quality of the concentrate obtained during enrichment. One of the most common technological schemes of this type is the release of one commercial product. It is used only in the enrichment of steam coal of such grades, of which several classes of sizes were not identified during the processing. A striking example of such a scheme was coal labeled P.

rules

In fact, there are few rules for coal enrichment. To be precise, it is only one, but rather important and consists in the fact that it is necessary to observe all production processes during the processing of rock. Such mandatory processes include sorting by fractions and directly enrichment of the product. Since the breed initially cannot be the same size, it is conditionally divided into large, medium and small, and then sent to the screening stage.