In livestock farms, silage and silage technologies are widely used. They suggest performing operations of drying the vegetation, after which the feed preparation enters the sealed storage. The use of high-quality haylage allows for the provision of cattle with feed at minimal cost. At the same time, some methods of preparing herbal mass make it possible to use an already finished product in the form of a dry mixture, which also opens up opportunities for mechanization of the feeding process. Obviously, the technology of harvesting silage and silage can significantly increase the efficiency of farming. The main thing is to correctly implement the method in practice.

What is haylage?

Haylage can be considered in many ways. From a functional point of view, this is the feed base for livestock, and if we consider the material taking into account its origin, then we should talk about the totality of the masses of plants of different varieties. Usually, forage harvested using special technology from cereal and leguminous herbs is considered to be haylage. Of considerable importance in the process of creating the material is the storage method. Among the key conditions for the implementation of this stage of the procurement is a complete lack of access to air. According to technologists, this nuance allows providing the future feed with the necessary nutritional base. On the other hand, harvesting haylage in such conditions cannot but contribute to the development of harmful bacteria.

Preparing plants for hay

For harvesting, it is recommended to use not only legume-cereal plants, but also alfalfa with clover. High-quality hay from legumes can be obtained only if mowing was carried out at the budding stage. If we are talking about cereals, then the optimal phase for assembly will be the exit to the tube. Violations of the timing of the beginning of the bevel of plants affect the quality of the feed, in particular this applies to cereal grasses.

Mowing at the stage of vegetative development contributes to the endowment of the feed mixture with crude protein. At the same time, silage and silage harvesting should be planned in advance, since the mowing period should not exceed 10 days. The high speed of harvesting is due to the fact that the drying of the harvested mass on the field is unacceptable due to the loss of useful properties of the material. Also, during the harvesting of grasses, the technique should ensure uniformity of the drying of the feed.

Determination of plant moisture

Immediately after collection, it is important to determine the moisture content of the harvested mass. With a liquid content of more than 60% in herbs, further storage will occur as a silo. If the humidity level is reduced to 40%, then loss of important feed elements can be observed. At a coefficient below 20%, a decrease in carotene concentration is observed. For this reason, it is necessary to carefully monitor the moisture content of raw materials. There are different ways to do this. In particular, the classic technology for harvesting silage and silage involves the use of a Chizhov moisture meter. Also, the moisture level can be determined by repeated weighing technique. In practice, this parameter is controlled as follows: 10 kg of mowed vegetation is laid out on a frame with a gauze tight, just like on a stubble. If the sample reaches a weight of about 6 kg, then the mass is considered suitable for canning.

Hay Bookmark

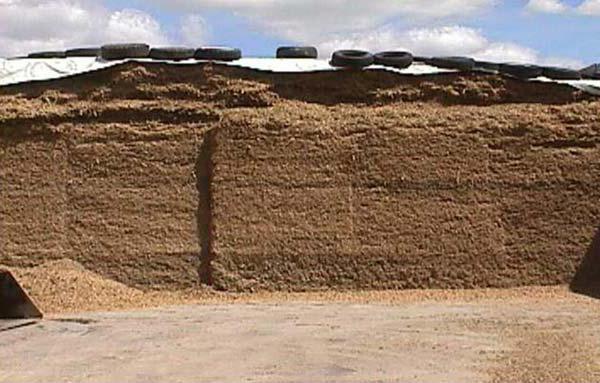

The finished mass is laid in concrete trenches with airtight plastic wrap. At the edges, the material deepens between the walls and the preserved vegetation to a depth of about 50 cm. Next, quicklime is sprinkled with a 2-centimeter layer , this measure helps protect future feed from rodents. Also, harvesting haylage in a film provides for laying straw with a layer about 25 cm high. But this method of conservation requires that the grass be mowed as high as possible. This is due to the fact that the selection of rolls can be performed according to the same methodology as in the case of unshredded grass. That is, the grass to be laid will have different characteristics, but further tampering operations are performed with the same load.

To reduce the difference in the initial parameters of cereal and bean grass, it is recommended to increase the cut level in some cases. The fact is that the technique for harvesting haylage at the mowing stage involves the use of balers, choppers that equally serve grass of different varieties. Balanced control of the cutting height allows you to lay in one trench and unmilled mass.

Film stacking

After the formation of the main mass for conservation on top in order to seal, you can lay another layer of grass. After this, the final shelter of the rammed mixture is performed. For this, a canopy based on a polymer film can be used. In this case, overlapping is not recommended. In places where edge overlays are formed, mold development processes are often observed at a depth of silage up to 20 cm. It is advisable to glue parts of the films into panels that correspond to the size of the trench. The polyethylene material can be rolled along the edges by heat welding, and polyvinyl chloride is optimally bonded with glue. Also, haylage blankets with shelter can be carried out using adhesive tape. It is recommended to form a flooring from strips with a width of at least 8 cm. After the operation is completed, the surface of the film is covered with earth, peat and sawdust. The purpose of this coating is a bit like mulching, which protects the ground and plants from freezing.

Optimal storage conditions

If the main task in the preparation of raw materials for haylage is to control the humidity of the grass, then after laying it is necessary to pay attention to the quality of sealing. The quality of protection of the material from self-heating depends on this. In other words, it is important to ensure the complete cessation of airflow access to the hay mass. Oxygen penetrated into the formed trench is quickly absorbed by plants. As a result, the mass loses nutrients, harvesting haylage in the future will be ineffective. This kind of harmful phenomena can only be prevented if tightness is maintained, which is achieved at the stage of laying film-free material without seams. Experts also provide for the implementation of a whole range of measures to combat the development of microbes. In particular, if you increase the concentration of dry components in the mixture, this will slow down the reproduction of putrefactive and butyric acid bacteria. Measures to eliminate molds, as a rule, boil down to the compaction and hiding of the hay mass.

Haymaking Technique

The method of producing a notch has its own nuances. The fact is that the space of the closed storage is filled with carbon dioxide and partly with nitrogen. At the time of depressurization, this mixture is replaced by air, resulting in the active development of harmful microorganisms. For this reason, it is important to use the feed as quickly as possible while rationally digging. If the silage preparation was carried out in a trench, then after removing the shelter, the mass should be cut with vertical layers with a height of at least 50 cm. Cutting and subsequent excavation are done so that the integrity of the remaining formation is not disturbed. It is not difficult to comply with this requirement if the operation is carried out using grader loaders.

Features of a roll of silage

This technique of preservation of haylage involves the implementation of the workpiece with the mass not in the trench, but in special packaging. But before this, rolls are formed with grass pressing. As a rule, the stocking of haylage in rolls is carried out with the help of grab-tilters. This is equipment that allows you to twist layers of plant mass while maintaining the desired shape and observing the requirements for strapping.

The laying of material in the package is carried out directly at the storage location, not far from the farm. The faster the mass is driven into the container, the more likely it is to preserve nutrients, including protein, sugar, carotene, etc. As the technology for preparing silage in the package requires, the material for providing sealing must be a cylindrical film, for example, agra-stretch.

Benefits of Roll Hay

For the most part, the advantages of this method are due to the high mechanization of the process. In any case, the use of modern technology allows to increase the speed of roll formation, to ensure the preservation of the useful properties of the feed. The advantages of the film itself, in which the rolls with grass mass are laid, are also noted. It provides a sealed storage, reliably protected from moisture, air and ultraviolet rays. As a result, the stocking of haylage in the package allows increasing the productivity of livestock farming. Eliminating the need to use concentrated feed additives, for example, leads to an increase in milk yield.

Determination of haylage quality

In the process of maintaining the harvested mass and before the excavation is carried out, organoleptic control is carried out to determine the qualitative characteristics of the future haylage. In particular, specialists fix the structure of the material, smell and shade. If the haylage harvesting technology has been correctly observed, the color will be olive or yellow-green. As for the smell, it should resemble a sour-fruity shades. In this case, the mass should not be smeared, as well as have mucus. At the same time, it may well preserve whole leaves, fragments of stems, grains and beans. The most important thing is that no traces of mold and fungal processes are present in the haylage.

Conclusion

The concept of haylage itself stems from the desire of farmers to save feed resources. At the same time, the use of this technology does not mean a decrease in the quality of the cattle food product. It is on the preservation and maintenance of an adequate nutrient base that the harvesting of hay and haylage in a traditional form is oriented. This applies not only to the requirements for the content of the finished base for the feed, but also to the stages of preparation of the herbal mass. In particular, even at the bevel stage, it is recommended to properly prepare the material for further laying, to determine, among other things, humidity indicators. Further, the control of ensuring the safety of useful elements provides for compliance with the rules for laying haylage and its further removal.