Oil and gas refineries are necessarily provided with means to prevent technological leaks into the open air. For this, special devices are used that are connected to safety valves and production plants. To burn excess gases and vapors, flare systems are used that are connected to the channels of technological waste disposal at energy enterprises.

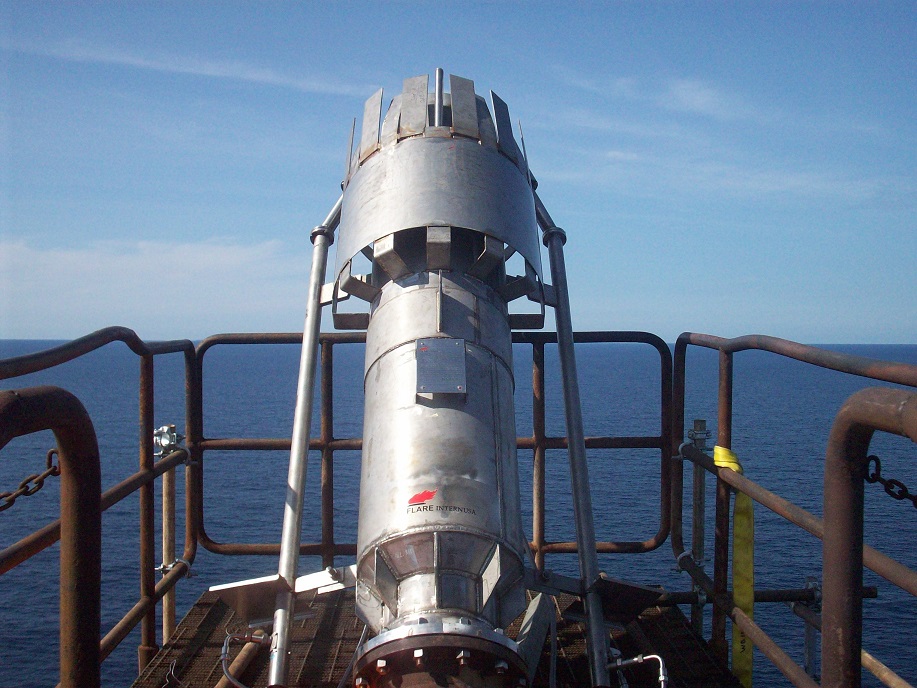

Flare Unit

This type of equipment is included in the general technological infrastructure serving the processes of extraction, storage and transportation of oil and gas mixtures. The system includes a network of pipelines, flare shafts with heads, burners, valves, as well as automated control and monitoring facilities. In addition, the device of the flare system is not complete without devices that ensure safe combustion of fuel. The number of combustion points depends on the project volumes, which, in principle, can be served by a specific infrastructure. This parameter is closely interconnected with other operational properties of the facility. For example, if less than three burner shafts are used, then in order to maintain a flame, the design of the installation should include a windshield.

The gas-air mixture supply channels are brought to the burners, and the circuit with the ignition mixture to the ignition device. To normalize the combustion process at different times of the year, installations are provided for regulating individual temperature and humidity conditions. In cold weather, for example, to avoid the possibility of freezing in the pipes supplying fuel mixtures, pipe heaters can be connected. Special requirements are also presented for gas. Flare systems work stably only under condition of preliminary drainage of the served mixtures - in any case, this applies to operation in winter time.

System functions

The primary tasks of torches of this type include the combustion of associated gas mixtures in order to exclude their accidental release into the atmosphere. This applies not only to gases as such, but also to various process vapors, which also pose a danger to the environment. In this case, different torches may vary specific tasks. From the point of view of the functional orientation, two basic types of installations can be distinguished:

- Are common. The most common flare systems that are used in production facilities. They include in their own infrastructure many additional technological tools, such as a separator, a water trap, a fire arrester and a collector.

- Separate. Such systems find their place in the existing general flare infrastructure. This combination model is used in cases where the main associated gas combustion system is not able to fully service the discharge products.

There is also a special group of special systems. A key feature of this type of flare is the ability to work with process mixtures that cannot be disposed of by common and separate flare units. These ejection products include:

- Products decomposable by heat.

- Substances reacting with other release products.

- Highly toxic and aggressive mixtures.

- Air-gas mixtures, including mechanical impurities.

Horizontal and vertical systems

Depending on the design conditions at the enterprise, the operation of horizontal or vertical flare units can be organized. The constructions of the first type are mainly involved in the purging of wells, loops and production lines. Such systems are characterized by the use of burner barrels, which are capable of providing sufficient air injection, which makes it possible to conduct smokeless combustion. On gas wells, according to the instructions, horizontal burners of a simple design should be used that will ensure the disposal of products containing liquid plugs and mechanical impurities. At the same time, in order to maintain the safety of horizontal flare systems, a moderate heat flux density should be maintained at a level of up to 1.4 kW / m 2 . To protect the personnel servicing the operation of such systems, additional means of minimizing thermal effects in the form of protective shields can also be used.

Vertical installations are completed with pumps and devices for condensate discharge. The functional basis of the structure is formed by the head, which is a metal device for regulating the delivery of the gas mixture. In some models of systems, they also exclude the passage of flame to the barrel of the installation. At the end of the vertical barrel, burners with a windproof visor are placed. Ignition can be installed both in the structure of the head and in the barrel. Ignition pipelines are supplied to the burners in a separate order. The technical guidance for flare systems requires that flame control, irrespective of supervisory control, be carried out by means of ionization probes, thermocouples, acoustic or optical sensors.

Features of closed flares

This kind of gas torch is intended for burning technological combustible mixtures near the earth's surface. Closed installations include a combustion chamber, the surfaces of which are treated with a protective lining. Unlike a burner, such equipment has a higher productivity, but increased requirements are also imposed on it in terms of providing protective properties. As noted in the Flare Systems Safety Manual, enclosed chamber chambers should be fenced in order to prevent uncontrolled air access. The torch must ensure complete utilization of the incoming gases in the absence of a visible flame. The air flow necessary for maintaining combustion along with the return exit of flue gases is organized through natural or forced draft with the possibility of controlling the throughput.

The burner unit for closed flare systems is selected with the expectation of ensuring stable and sustainable combustion. Reliability requirements in this case are higher than in the case of conventional open type installations. According to the regulations, combustion with pulses and resonant vibrations of the flame should be excluded. This is guaranteed by the uniform flow of oxygen into the combustion chamber.

Requirements for facilities for the operation of flare units

Associated gas utilization systems are located taking into account the wind rose and the technical capabilities of installing pipeline lines with fences and exhaust channels for burners. Regardless of the type of installation, regulatory distances between flare shafts, buildings, engineering structures, warehouses and electrical substations must be maintained. Specific distances for the direct placement of burners on the territory of the enterprise are calculated on the basis of the planned density of heat fluxes of the flare system. The rules also indicate the need to create conditions for repair and maintenance of shafts during operation of neighboring installations. In this regard, it is recommended that ladders are placed for personnel from the side of the barrel opposite to the location of the adjacent burner. Materials for the manufacture of structures that are in the zone of activity of heat flows must have a fire-resistant structure or special heat-resistant coatings.

Flare technology requirements

The organization of gas torches is largely determined by the requirements of the general technological process at the enterprise. Nevertheless, the stage of interaction of gas sources and burners is also regulated by regulatory documentation. At the design stage of the system, the discharge parameters must be determined - in particular, indicators of pressure, temperature, density and flow rates. Based on the calculations made, a scheme of discharge into the flare system of the most suitable type is being developed. Discharge sources should also be able to supply not targeted workers, but preventive gases, which include inert and purge mixtures. Conversely, compounds including acetylene, hydrogen, carbon monoxide and quick-burning components should not be sent during discharge. Separators responsible for the separation of solid particles and droplet liquid in vapor and gas mixtures may be included in the composition of a technological combustion plant. These substances and components are processed in separate flare devices.

Rules for the operation of flare systems

Before each start-up of the installation, it is necessary to purge the barrel with inert gas mixtures in order to remove oxygen. Further airing of the flare channels is prevented by the control valves for extinguished burners. The oxygen level is checked by taking samples with their further analysis. During the combustion process, it is recommended to set the burner speed to the following modes:

- For the head with a gas shutter - not less than 0.05 m / s.

- If there is no gas shutter, not less than 0.9 m / s.

- When supplying an inert gas - not less than 0.7 m / s.

Also, when operating flare systems that are not equipped with gates, the purge mixtures must have a density of more than 0.7 kg / m 3 .

Before stopping the discharge of process gas or heated vapors, it is recommended to connect in advance channels with the direction of inert mixtures, which will eliminate the formation of vacuum during condensation or cooling. Before performing maintenance or repair work, the pipelines are disconnected from the flare unit from the discharge of gas mixtures and ignition. Residues of combusted gases, as well as smoke mixtures, must be completely removed from the channels. Prior to technical work, the trunks are purged with nitrogen and, if necessary, steamed.

Flare Controls

Ignition is carried out by the so-called running fire or electric spark system on the standby burner. Further combustion control is carried out by acoustic sensors and a thermoelectric converter. For control, an autonomous ignition and flame control unit is also used, which should be in a separate cabinet with heating. Operating modes with the automation connected involve work according to the specified algorithms with the transmission of signals to the operator console. To activate emergency modes or automatically connect the operator panel, certain signals are set. For example, a guide to flare systems in the event of a failure to ignite a flame after 10 cycles indicates the need to automatically trigger an alarm. If the fire detection sensors do not work, then a remote control console is connected to the work. With its help, the staff already takes over the control functions through the interface to control the ignition of the flare unit.

Flare Safety Guide

Regulatory requirements establish the following safety rules for the operation of gas flares and related technological systems:

- When organizing gas discharges from a flare shaft into the atmosphere, the permissible content ratios of harmful substances must be observed.

- In order to prevent the formation of explosive mixtures, the rules for safe operation of flare systems require regular cleaning of the discharge circuits of gas mixtures.

- It is forbidden to direct substances into the combustion chamber that could provoke an explosion. Such substances at oil and gas enterprises, in particular, include chemical oxidizing agents and reducing agents.

- The territory of the technological installations operating flare equipment must be fenced.

- Only persons with the appropriate qualifications and verified on industrial safety issues should be allowed to service gas flares.

Conclusion

The technologies for burning working gases at modern enterprises reach a fairly high level in terms of reliability and safety. This is largely due to the use of innovative means of control and management of complex processes of burning combustible mixtures. For example, the safe operation of flare systems at the current level is impossible without the use of automated control elements with the connection of sensors and industrial controllers. At the same time, the manual control mode is not excluded - at least it is provided as an optional one. Operator panels still bear great responsibility in the processes of regulating the operation of flare plants, tracking their parameters and diagnostic indicators. Along with this, the design of burners with trunks forming a flare infrastructure is also being improved. Manufacturers are using increasingly reliable materials with heat-resistant coatings and high mechanical resistance. All this allows us to optimize the overall processes of oil and gas enterprises at the proper level of safety and environmental protection.