From the fundamentals of the Human Resource Management discipline, it is known that personnel are the totality of employees working in a particular enterprise, according to the terms of the employment contract. Sometimes this population is called the state.

The entire staff of the company is usually divided into two large categories: non-production and industrial production personnel.

Non-production workers

Non-productive or non-industrial personnel - this is the staff that works at facilities related to non-productive funds. These objects are on the balance sheet of the enterprise and do not participate in the production directly. A vivid example of such institutions will be sanatoriums based on a large machine-building enterprise (hospital, kindergarten, canteen, palace of culture, club, etc.).

The concept of industrial production personnel

This group of workers is directly involved in the production of products and ensuring a continuous production process. The staff of the main, service, auxiliary and auxiliary production belongs to the category of industrial production personnel. Also, it includes employees of research and development bureaus, managing niches, as well as security structures.

The industrial and production personnel of the organization as cells of the organs of one large organism - the company, without which the life cycle of the enterprise will not last long or even end.

Company Staff Classification

As mentioned in the introduction, the company’s personnel are divided into two large subspecies. Industrial production personnel, in turn, also consists of two links: a management link and a production link. We will consider them in more detail, and for clarity, we turn to the diagram below to visually represent what will be discussed.

Management staff

In order for the company to successfully operate in the market and sell products with high efficiency, the owners need to assemble a team of highly qualified workers in industrial production personnel in the field of management. They are usually divided into three more groups. These are managers, specialists and employees.

Managers are usually assigned to a specific unit in the organization and oversee its work. They are authorized to make the necessary decisions and give orders, according to their official duties. Managerial employees are involved in setting goals and arranging the work of their unit in such a way that in the future all the plans outlined are fulfilled.

Specialists differ from managers in that they do not have people subordinate to them. They are engaged only in solving assigned tasks and finding solutions to specific problems. And it is only for these very decisions and options that they are responsible to the chief executives. Examples of such posts are the designer, lawyer, sociologist, technologist, and others.

The employees are technical executives who provide the management process for the movement of information flows in the organization. They are engaged in paperwork or provide the necessary conditions for senior management to work. For example, secretaries, cleaners, drivers, cashiers, archival workers.

As you can see, managerial work has specifics - it does not produce material wealth, but provides information flows, decision making and control of their proper implementation.

Production personnel

Depending on whether a person produces products or ensures the production process, workers of industrial production personnel are divided into main and auxiliary.

The main production worker, one might say, creates products with his own hands. Sometimes such workers use special devices or tools. For example, the installer of numerically controlled milling machines. He is engaged in processing the part, gives it the desired shape. It is clear that he does not scrape metal for himself, but uses special milling machines and with the help of the written program he gives the details the necessary shapes and monitors the correct processing of the product.

The auxiliary workers include the staff that is engaged in the implementation of maintenance and support operations. These works are necessary for the normal course of the production business process. For example, an auxiliary worker is engaged in transportation, warehousing, storage of valuables, equipment repair, preparation of hardware and equipment for work, product quality control and other responsibilities.

Another type of division of personnel is also considered important. Employees of the company may differ in their profession, specialty and qualifications. Under the profession understand the type of activity, characterized by industry affiliation. A profession requires certain knowledge, skills, and also speaks about specific working conditions. For example, take the profession of a teacher. The profession belongs to the education sector.

For almost every profession, there is a division into specialties. The specialty is a subspecies of the profession, characterized by a narrow focus. Bearing in mind the specialty, we mean a deeper level of training in a particular industry. Continuing the topic of practical examples, we consider such a specialty as "primary school teacher." From the name it is clear that a person needs in-depth knowledge in the field of teaching precisely at the junior level.

However, in most cases, this separation of workers by profession and specialty is conditional.

Another important characteristic of personnel is qualification - the level of professional training of the employee. In practice, it turns out that with the NTP movement in production, knowledge becomes more popular, and skills, on the contrary, fall outside the scope of duties of machines and computers.

In terms of training, the company’s staff is unskilled, unskilled and qualified. The first type does not require certain knowledge to carry out work. The second involves on-site training for six months, and the third requires special training for 2-3 years for successful and accurate performance of work duties.

Workers Responsibilities

The most important duty of workers of all time is the performance of work in accordance with an employment contract and job description. In specific cases, these obligations may be joined by others for certain surcharges specified in additional agreements.

Recently, the role of auxiliary workers in the production process has changed dramatically. Now, in most cases, this is the staff that serves the automated and mechanized production. And in the age of robots, company management increasingly has to either reduce support staff or completely review personnel policies.

Tariff Discharges

At manufacturing enterprises, personnel are distinguished by the presence of tariff categories. These indicators are still used in calculating the wages of workers. The tariff category is determined by two values: the level of complexity of the work performed and the level of professional training of the worker.

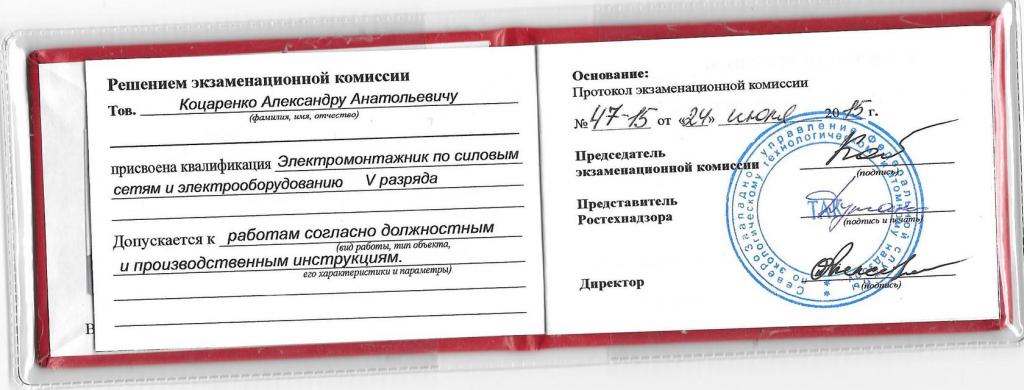

It must be said that the tariff category characteristic is inconsistent up to a certain point. So, for example, the same adjuster of CNC milling machines, who has the 4th grade, is already trained at the enterprise in certain disciplines and receives 5th grade according to the results of exams, which gives him certain privileges. These include: increasing the tariff rate of remuneration, admission to the implementation of more complex and labor-intensive work. After some time (after practicing the acquired knowledge in practice and assimilating it), he can again try himself in obtaining a higher level. But the number of discharges is not infinite. Each profession and specialty provides its maximum number of tariff categories.

Calculation of the need for employees

It helps to obtain information on whether it is really necessary to expand the staff, to determine the number of industrial production personnel by professions and qualifications.

The need is current or prospective. The current number is determined by the sum of the necessary basic personnel, based on production volumes, and the additional need for personnel.

The basic need is the ratio of production to the production of one worker. In this case, it is better to divide the workers according to the principles of payment and categories.

The number of additional personnel is calculated by the difference between the total need for staff and its availability at the beginning of the period.

The prospective number of industrial-production personnel of the enterprise is the product of the average number of employees and the coefficient of saturation by specialists.

The last variable is found by the ratio of the number of specialists to the volume of production.

It is also advisable to calculate the standards for the number of industrial production personnel on the basis of production areas, units of jobs and standards for servicing equipment.

Salary

For the industrial and production personnel of the enterprise, there are two types of remuneration: time-based and piece-rate. For the main workers, the time-based is not motivational, as they hope to receive a salary or tariff rate multiplied by the hours worked.

With the piece-wage form of remuneration, workers will receive money only for manufactured products in accordance with the prices of the enterprise. For those workers who have an influence on the number of products produced most often and establish piecework wages. It is here that the already mentioned tariff schedule and labor intensity standards or work rates will come in handy.

Training

When an enterprise purchases new ultra-precise and high-tech equipment, it needs to have highly qualified personnel working for it. And since such specialists are rarely found immediately, the company management is forced to send existing staff for retraining or advanced training.

Training can be individual, team or course. Forms of professional development are: industrial and technical courses, training in the second specialties, special-purpose courses, schools of masters and schools of advanced labor methods.