Kyshtym Copper Electrolyte Plant is one of the ten most advanced non-ferrous metallurgy enterprises in the world. The plant is a city-forming company, where most of the population of Kyshtym is employed.

From the Demidov Empire

The Kyshtym copper electrolyte plant, like many industrial centers in the Urals, was founded in 1757 by Nikita Demidov. The company was engaged in iron casting under the famous trademark "Old Sable", whose products were known in Europe and were very much appreciated. The Kyshtym plant was one of the fifty industrial enterprises of the Demidov dynasty, deployed in the Urals with all the breadth and grip of a Russian pioneer.

In England, roofs were covered with metal from Demidov factories , and in Russia, the floor of the Trinity Cathedral of the Kiev Pechersk Lavra was laid with iron plates. The metal was of such high quality that it was purchased in England and Sweden, where the manufacture of iron was a national pride.

Iron smelting in Kyshtym lasted 150 years. In 1873, the plant was ranked among the best manufactures in Russia and the Urals, recognition of achievements occurred at the World Exhibition in Vienna.

Trail of Edgar Hoover

In 1809, the plant was bought by gold miner Lev Rastorguev, after his death, he was inherited by successors. According to the concession, in 1907, the ironworks passed into the possession of the English company Urkarta. The future president of the United States, Edgar Hoover, who worked as an engineer at the plant for a while, also had a hand in the case of buying up shares in the plant.

Hoover created a joint-stock company of Kyshtym mining plants, which bought back shares from the heirs of Rastorguev. In the KMEZ museum you can see a noteworthy entry in the old account book about how many shares of the Ural plant belonged to Hoover.

For economic reasons, iron smelting in 1908 was reoriented to a more profitable and demanded business - refining copper. The choice was not accidental, the era of electricity came and the need for copper products increased.

After the revolution

After 1917, all private companies were nationalized. The Kyshtym Copper Electrolysis Plant began producing products for the national economy since 1920. The ingots remaining from the tsarist times were used, from which they began to make rolled copper wire.

The expansion of the range of products occurred in the period 20-30 years. For the first time in the history of Russia, in 1928, industrial selenium was obtained at the plant and mass production was established. The beginning of the thirties was marked by the invention of the method of obtaining tellurium and the introduction of technology in the enterprise. When glass was made for the ruby stars of the Moscow Kremlin, selenium from the Kyshtym plant was used in the alloy.

In 1937, the company launched a mass production of copper sulfate. During the Great Patriotic War, the products were oriented towards the needs of the front. During the post-war reconstruction period, the plant was significantly expanded, which made it possible to master the production of rolled copper foil from copper by the electrolytic method by 1961, which was also done for the first time in the USSR.

The Kyshtym copper electrolyte plant experienced a rebirth in the eighties, when a radical reconstruction of the entire production and auxiliary funds was carried out. The process was completed during the perestroika period, in 1995. In addition to transformations in the industrial sector, the plant managed to build a housing estate for employees and increase staff.

By the level of equipment used and technological processes, the enterprise was included in the top ten leading companies, which is marked by certificates in accordance with the requirements of ISO 9001: 2008. The company is independent in making decisions on many issues, Kyshtym Copper Electrolyte Plant, TIN 7413000630.

Modernity

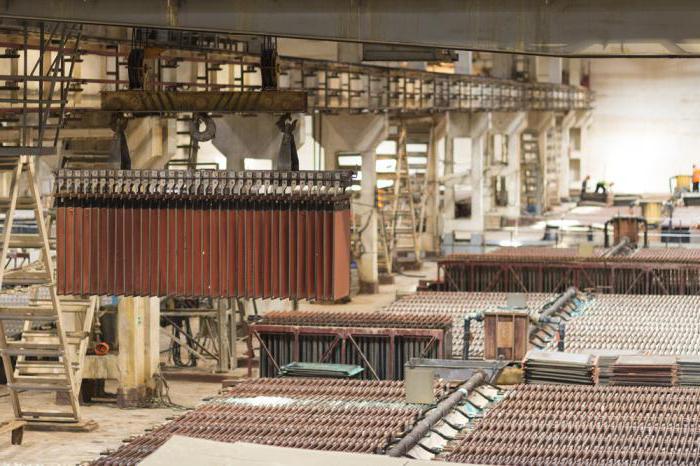

In 2003, the Kyshtym Copper Electrolyte Plant was acquired by the Russian Copper Company. In 2005, another reconstruction was carried out at the enterprise, the purpose of which was the second anode furnace, and an electrolysis workshop was also built and launched under the project of the Finnish company Outotec. The measures taken allowed to increase the annual production of copper cathodes up to 120 thousand tons (starting capacity was 80 thousand tons).

Two years later, Kyshtym Copper Electrolyte Plant CJSC increased the production of wire rod by continuous casting. For this, the new American equipment SCR 2000 was installed. This step allowed us to increase the output of products demanded in the world and domestic markets up to 100 thousand tons during the year, strengthening the position of KMEZ. Today, about 15% of all wire rod in Russia is produced by this enterprise.

Company structure

Kyshtym copper electrolyte plant is located in the Chelyabinsk region. The number of working personnel is 3400 specialists. The production structure of the enterprise includes:

- A smelter producing 112 thousand tons of finished products per year (copper anodes).

- Copper electrolysis workshop, consisting of three departments - copper electrolysis (product purity 99.9%), copper sulphate production, refining department (production of gold, silver bullion, platinum and palladium in powder).

- Workshop of copper wire rod (diameter 8 mm, three quality classes - A, B, C).

- The laboratory, which includes seven departments equipped with modern equipment.

- Social sphere ensures stable work of company employees. The plant provides support to the KMEZ museum, the Council of Veterans, an annual professional examination of all employees of the enterprise is carried out, free access to sports is provided, a children's camp is open for children, all employees can spend their holidays at the Travakul base. For children and adults, cultural leisure, creative development is available in the factory of Metallurgists' recreation center, where there are circles, amateur groups, etc. Many holidays and events are celebrated by the Kyshtym copper electrolyte plant. Photo reports of events decorate local newspapers.

- Ecology. Preservation of the environment is ensured by modernized protection systems - filters, closed-loop water supply to the production, dust and gas treatment plants, etc. All measures and equipment are monitored twice a year. Since 2000 , the Kyshtym Copper Electrolyte Plant introduced an environmental management system of ISO14000 standard (international certificate).

Products

Kyshtym Copper Electrolyte Plant (KMEZ) in the main assortment produces:

- Copper cathodes of the M00k brand.

- Three types of copper wire rod.

- Refined gold (bullion).

- Refined silver (bullion).

- Measured bars of gold 999.9 samples (weight - 500 and 1000 grams).

- Copper sulfate (grade I, grade A).

- Technical selenium.

- Reagents "Copper" and "Nickel".

- Copper foil.

- Radiator copper tape.

- Cutlery made of steel, anodized iron.

The company's products are purchased by both Russian and foreign companies. For domestic needs, about 500 thousand tons of copper per year are required; KMEZ produces up to 900 thousand tons of copper products for various purposes. Most are exported to Europe, the Middle East and other countries in the form of concentrates, wire rod, anodes. Precious metals - gold, silver and platinum produced by KMEZ are highly appreciated by jewelers around the world for quality and purity.

Consumers and tenders

KMEZ manufactures products focused on the manufacturing sector of the economy. The main consumers are metallurgical, machine-tool, hardware and other plants. Constant customers of the products are such enterprises as Kopeysk Mechanical Repair Plant, CJSC Karabashmed, LLC Introbusiness, etc.

The Kyshtym Copper Electrolyte Plant holds tenders for the purchase of basic raw materials for its workshops. Interests include:

- Materials, scrap containing copper.

- Copper concentrate.

- Scrap brass, bronze, copper, waste cable production and products, electric motors, etc.

- Precious metals in scrap.

- Mineral, primary and secondary raw materials.

In addition, tenders are held for the purchase of equipment, maintenance of equipment, prevention of technical structures, production lines, etc.

Jobs

The company carries out about 120 types of activities, and qualified personnel are required at each site, which undergoes rigorous selection at the Kyshtym copper electrolyte plant. Jobs appear infrequently, since the staff is fully staffed. But periodically, the personnel department announces vacant posts.

At the beginning of the summer of 2017, workers and engineers are invited to the plant. The company needs loaders (salary from 10 thousand rubles), engineering staff (salary about 27 thousand rubles), product promotion managers (salary from 40 thousand rubles), equipment repairmen ( salary from 15 thousand rubles), cook (salary from 13 thousand rubles), as well as a specialist in public relations (salary based on the results of the interview). The telephone number of the KMEZ personnel department is on the official website.

Address

The Kyshtym Copper Electrolyte Plant is located in the city of Kyshtym, Chelyabinsk Region, on the street of the Paris Commune, in building No. 2. The representative office in Chelyabinsk is Entuziastov Street, building 22-1.

You can find on the website of the Kyshtym copper electrolyte plant and contacts of the Moscow representative office, which is located at 18 Goncharnaya Street, building No. 2.