The industry in which the use of assembly units is most pronounced is engineering. Machine assembly units are the smaller parts that make up a complete vehicle.

Definition

The use of such parts is carried out in various fields, but the essence of the assembly process does not change. It is also worth noting that before creating the unit, a drawing is made, according to which it is necessary to manufacture the part. An assembly unit is a part consisting of several parts, which, in turn, are connected by some assembly method. Their production is carried out by the manufacturer, which is engaged in the further assembly of the finished product.

It is worth noting that such a term as an assembly unit is not always used, more often you can find another name - a node. It is also important to note that to facilitate the assembly process, they are divided into smaller groups - subnodes, and also assign orders to them.

Assembly of products

As mentioned above, the assembly of assembly units is carried out at the same factory, which is engaged in the installation of the final product. This is clearly seen in the field of engineering. However, some types of products undergo a full assembly already at the place of operation, for example, cranes or heavy presses. But it is important to note that even in such cases when the final stage of the assembly of the object occurs together with its installation on the foundation, the initial process of collecting the unit or its individual parts, i.e. assembly units, will still be carried out at the manufacturer of this product.

There are only a few cases that are an exception when the final assembly is not carried out at the factory. This applies, for example, to the assembly of aircraft or combines. The lack of installation of the finished product is argued by the fact that it is necessary to maintain the transportability of the units along the railway lines.

Assembly elements

The first element, which is the basis for any product that is assembled in production, is the basic assembly unit and part, or simply the basic part. There are constructive assembly units and technological assembly units (nodes).

A structural unit is understood to mean a part that is designed only taking into account the functional principle. The conditions for independent or independent assembly of a part are not specifically considered here.

A unit or technological unit is a product of an assembly unit, the installation of which can be carried out separately from other components of the same unit or the whole product. Also, these nodes are able to perform their functions only together with other components. For example, you can take the cylinder head or block.

Units in order

It is important to note that for assembly units there is a classification in order. The first group includes those units, the installation of which can be carried out independently, separately from other parts. The same units that fall into the finished unit not directly, but through the entry into the composition of any assembly unit, receive the second order, third, etc.

Currently, for example, in engineering, they use the separation of the assembly into two stages - this is the general, as well as the assembly of individual units. The latter includes those operations as a result of which a first-order assembly is created from assembly units of the second, third order, etc. The general assembly includes all operations during which a ready-made unit is created from pre-prepared first-order units. Moreover, such an installation process can show the manufacturability of the process even at the installation stage. It is determined on the basis of whether it is possible to carry out parallel assembly of individual units and the finished product from these parts. If such an opportunity is present, then this significantly reduces the time required to complete the operation.

Blueprints

To create any objects, you must first prepare a design document that contains all the necessary drawings for the manufacture of parts or the finished product. There are several types of such documents, one of which is called assembly. It contains a drawing of the assembly unit, as well as other parameters that will be needed for direct assembly and full control over the final characteristics.

It is worth noting that the assembly drawings are divided into several types: for electrical installation, hydraulic installation and pneumatic installation.

Assembly drawings are considered suitable for use only if they provide complete information about the assembly unit, its design, and how the various parts of the unit should interact with each other. Also, paper should fulfill the function of visual technical documentation, which must be guided during assembly operations.

What is a drawing for?

In the presence of an assembly drawing, operations such as:

- Assembly of the part, as well as its component parts, if any.

- Joint processing of several parts in the process of direct assembly of a unit or after completion of this stage.

- Monitoring the resulting assembly unit.

In addition to these data, if necessary, the drawing may contain information about how the resulting product should work, as well as how exactly all its components should interact. The development of such documents is carried out for each unit in a separate order. Preparation of an assembly drawing for each of the nodes should be carried out at the stage of preparation of design documentation, since this paper is mandatory.

The initial data used to create the assembly drawing are general drawings, as well as the product specification. The details of the assembly unit, or rather the drawing for each component that will be included in the final node of the first order, must also be indicated in the documentation.

What should be indicated in the drawing

Based on GOST 2.109-73, we can say for sure what each drawing should contain.

- The first thing that a document should contain is an image of a part, from which it will be possible to clearly determine the location of each part, and also what relationship should be between them.

- The second necessary parameter, which must be indicated on each drawing, is size, deviation or other requirements, the fulfillment of which is strictly necessary.

- The nature of the coupling should be indicated if it is not specified by specific numbers, but is specified by fitting parts.

- The method for establishing one-piece joints - welding, soldering, and so on, should be indicated.

- The full dimensions of the final part.

- Technical parameters of the finished product (only if necessary).

- It is necessary to indicate the coordinates of the center of mass (if there is such a need).

Types of assembly

Like most industrial operations, specialists subdivide assembly units into types. This separation is carried out according to such characteristics as technological features of all types of nodes, depending on the method of their technological manufacture.

There are five main types of assembly of assembly units - this is welding, soldering, gluing, forming from polymeric materials and using threaded connections. In addition, there is a division into integral types of connections, detachable fixed, detachable movable, as well as detachable and one-piece.

The first type includes such types of compounds as:

- welded;

- soldered;

- glued;

- tourniquets;

- electrical and radio installation;

- combined;

- pressed in.

The second group includes such types of compounds as:

- threaded;

- buttoned up;

- pinned;

- bayonet mounts.

The following compounds can be attributed to the third type:

- straightforward;

- rotational;

- combined.

The last type includes the following types:

- crimp;

- locking;

- combined and others.

Classification

All classifications that were given above are considered common, and therefore do not require any further explanation. But there are a few exceptions that still have an additional explanation due to their classification method.

Harness assembly units are products that consist of wires, cords or cables, they are fixed to each other using threads, tapes, belts or using any other insulating means made independently according to the drawings. However, you can also use materials that are performed according to the wiring diagrams, and not just according to the drawings.

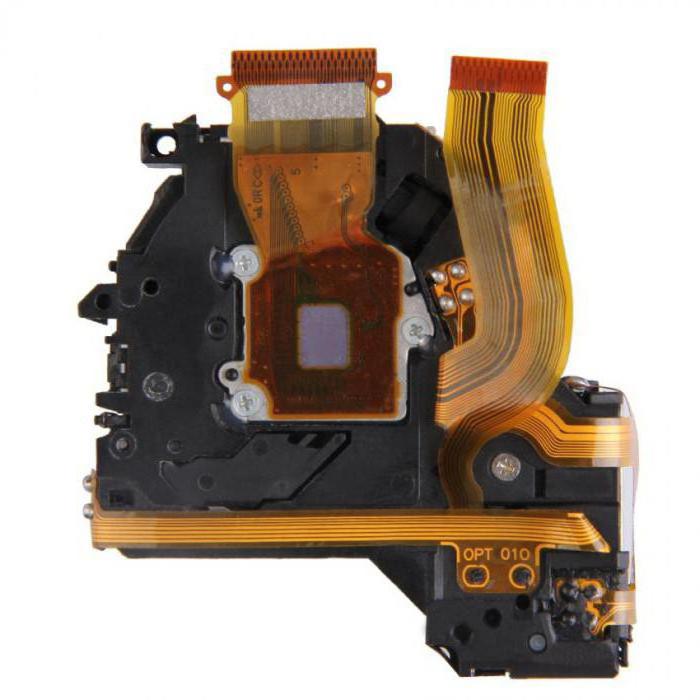

Electrical and radio installation includes assembly units that contain electrical elements, radio elements, wires installed and secured to an appropriate base to obtain electrical contact by soldering, welding or wrapping.