Science and progress make it possible to create unprecedented things that many could not even think of. Take, for example, such a relatively new development as synthetic gasoline. Many people know that this fuel is obtained by distillation from oil. But it can also be synthesized from coal, wood, and natural gas. The production of synthetic gasoline, although it cannot fully replace the usual way of production, still deserves to be studied. Therefore, its history will be considered, as well as methods for obtaining it.

Introductory information

It is difficult to imagine a modern civilization without motor fuel - diesel, kerosene, gasoline. They work cars, planes, rockets, water transport. But the amount of oil in the bowels is limited. Not so long ago it was believed that humanity would soon inevitably face a shortage of fuel. But it turned out that not everything is so sad. New technologies are being developed to extract hard-to-recover reserves, and alternative options are emerging. We can mention both green energy and improving the efficiency of resource use (modern small cars quietly cost 4-6 liters of fuel per hundred kilometers, although at the beginning of our millennium they demanded about 10). And high-quality fuel, as it turned out, can be obtained from various non-petroleum feedstocks.

How it all began?

You need to start with events that took place more than 150 years ago. It was then that industrial oil production began. Since then, humanity has consumed more than half of the so-called light raw materials. Initially, oil was used as a source of thermal energy. Nowadays, such an approach is not economically viable. When the automobile era came, the oil fractionation products became widespread in the role of motor fuel. At the same time, the more stocks of raw materials were depleted, the more profitable it became to look for an alternative.

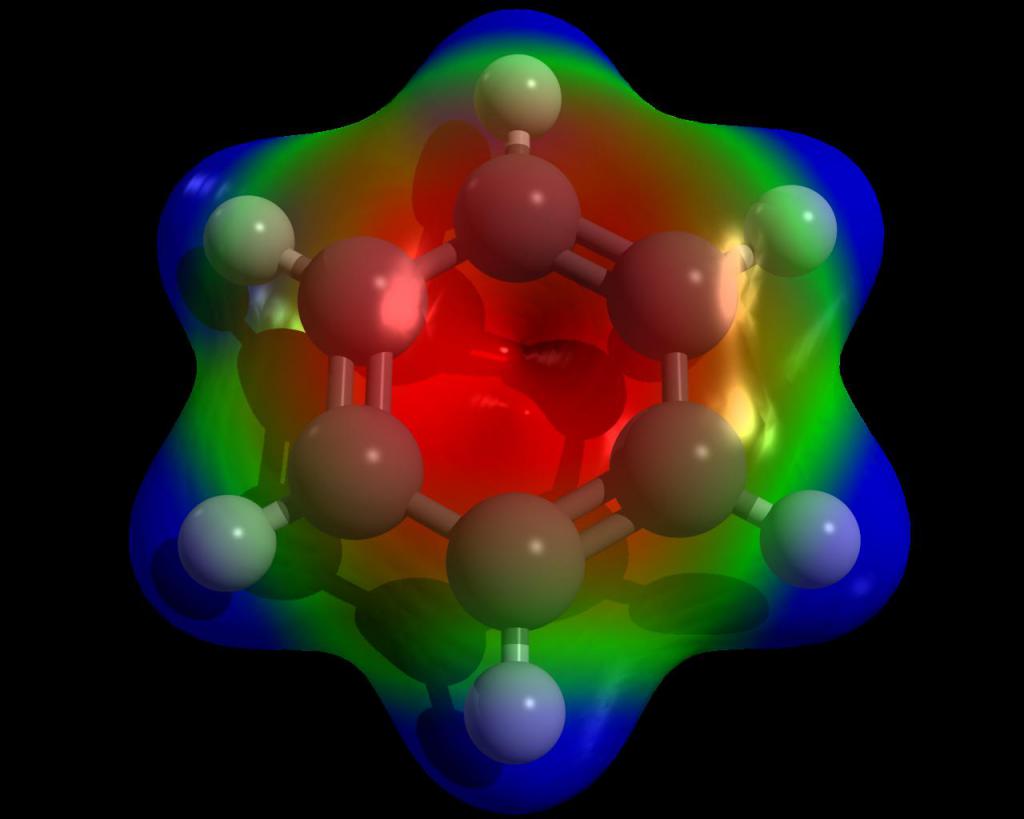

What is oil? This is a mixture of hydrocarbons, and more specifically, cycloalkanes. What are they? The simplest alkane is known to many as methane gas. In addition, there are nitrogen and sulfur impurities in the oil. And if it is processed correctly, then you can get many different materials. For example, take well-known gasoline. What is he like? In fact, this is a low-boiling oil fraction formed by short-chain hydrocarbons with five to nine atoms. Gasoline is the main fuel for passenger cars, as well as small aircraft. The next highlighted type is kerosene. It is more viscous and heavy. It is formed from hydrocarbons in which from 10 to 16 atoms are present. Kerosene is used in jet aircraft and engines. An even heavier fraction is gas oil. It is used in diesel fuel, which is its mixture with kerosene.

Scientific Search for Alternatives

Although the main fractions are obtained from oil, it turned out that other carbon raw materials can be used for this purpose. This problem was solved by chemists in 1926. Then scientists Fischer and Tropsch discovered the reaction of carbon monoxide reduction under atmospheric pressure. It was found that in the presence of catalysts, liquid and solid hydrocarbons can be created from the gas mixture. In their chemical composition, they were close to products obtained from oil. The result of chemical research was called “synthesis gas”. It turned out pretty easily. So much so that it can be repeated at home by any person who did not skip chemistry and physics at school. They got it by passing water vapor over coal (this is its gasification) or by converting ordinary natural gas (it consists mainly of methane). In the second case, metal catalysts were additionally used. It should be noted that synthesis gas can be created not only from methane and coal. A promising area is now considered work on the enzymatic and thermochemical processing of plant waste. We should not forget about the conversion of biogas, that is, volatile substances obtained through the decomposition of organic waste.

How did the application develop?

Nazi Germany excelled in this regard. During World War II, she had significant problems in terms of fuel supply. Therefore, entire complexes were created that processed coal into liquid fuel. And the synthetic gasoline of the Third Reich made a significant contribution, rather strongly delaying the fall of this terrible state. Then the method of chemical liquefaction of coal was used until pyrolysis fuel was obtained. By the end of the war, Nazi Germany managed to reach the level of 100 thousand barrels of synthetic oil per day. In more familiar measures, this is more than 130 tons! The use of coal is advisable due to the close chemical composition. So, in it the hydrogen content is 8% whereas in oil it is 15%. If you create a certain temperature regime and saturate the coal with hydrogen in a significant amount, then it will go into a liquid state. This process is called hydrogenation. In addition, it can be accelerated and volumes increased if catalysts are used: iron, tin, nickel, molybdenum, aluminum and many others. All this allows you to select various fractions and use them for further processing.

Synthetic gasoline is produced in Germany now. After World War II, the Republic of South Africa followed suit. Then began to connect China, Australia and the United States. It should be noted that we also have potential for the development of this area.

About the fall and take off

Before the start of World War II, the Soviet Union was searching for a possible extraction of gasoline from brown coal. But, alas, it was not possible to obtain results suitable for industrial production. After the conflict ended, the price of oil fell, and with it the need for synthetic fuel fell away. Now, due to the decrease in oil reserves, this sphere is undergoing a rebirth. The production of synthetic gasoline is becoming more common, often meets government support. For example, in the US, producers of such fuels can rely on government subsidies. Despite all the prerequisites, liquid fuel is produced on a limited scale. The fact is that the expansion of existing capacities is limited by a high cost, which significantly exceeds what is obtained from conventional raw materials. For example, synthetic gasoline in Germany can be made from water and carbon dioxide, only in a year it will cost a new car. And all because of the high cost of installation. The main area of work is the search for economic technical solutions. For example, the issue of reducing pressure to liquefy coal is open. Now it is necessary to create 300-700 atmospheres, and the search is conducted to achieve a value of 100 and below. Also relevant are issues of increasing the productivity of generators, developing new catalysts (more efficient). Yes, and we should not forget that there is not so much high-quality natural coal. Therefore, it is considered more promising to obtain it from gas. What opportunities are there?

Production from natural gas

This is especially true due to existing transport problems. So, if you transport natural gas, then the cost of this will be 30-50% of the cost of the final product. Therefore, it is very important to process it immediately near the place of extraction into high-quality gasoline and diesel fuel. This puts forward a number of requirements for compact installations. If you get the final products through the methanol stage, then this process is convenient due to what happens in one reactor. But it takes a lot of energy, because of which synthetic fuel is twice as expensive as oil. An alternative to this common method was proposed by the Institute of Petrochemical Synthesis of the Russian Academy of Sciences. It involves working with another intermediate substance - dimethyl ether. To work in this way is not difficult if you increase the proportion of carbon monoxide in the resulting synthesis gas. Obtaining synthetic gasoline in this case is additionally and quite environmentally friendly fuel. It especially showed itself well when starting cold engines due to the high cetane number. And for the production of gasoline, this option is not bad. So, it is possible to make fuel with an octane number of 92. Synthetic gasoline from natural gas at the same time has fewer harmful impurities than those that can be found in oil. The plant proposed by the RAS offers a working scheme according to which, the higher the reaction temperature, the greater the productivity.

Is it possible to do it all yourself?

Despite the fact that alternative energy is considered a relatively young science, it is not a problem to repeat its achievements within the same household. Therefore, yes, it is quite possible to create synthetic gasoline with your own hands. Moreover, given the specifics of the conditions in which it is necessary to exist, it is possible to rely on wood, coal and biogas. To each of them to give preference in the home environment - everyone decides for himself.

As the simplest, most relevant is the question of how to make synthetic gasoline from wood with your own hands. Many consider it exclusively as building material or raw materials for toys. But it is worth recalling at least wood alcohol, and it becomes clear that the potential exists. How to get synthesis gas in this case? It is necessary to take wood (or its waste, which is not important). At home, you can make a device of three parts, each of which will fulfill its function. Initially, it is necessary to ensure their drying and heating to a temperature of 250-300 degrees Celsius. Then comes the turn of pyrolysis. Here the temperature should rise to 700 degrees. And the final stage is gas generation. It launches steam reforming. The process takes place at a temperature of 700-1000 degrees. The result is a very pure synthesis gas. No additional intervention is required. Next, we use the catalysts, and synthetic gasoline is ready!

We make from coal

And one more small point that was not mentioned before is that when working at home, the installations will most likely turn out to be quite large. Therefore, placing them in an apartment is not recommended. But to create them in your own house or near it is a very real thing.

Synthetic gasoline can be obtained from coal as a result of the influence of steam. Its gasification is the easiest and most feasible way for home use. So let's get started. Initially, for greater work efficiency and an increase in the speed of the process, the coal must be crushed. Then it is saturated with hydrogen. Then you need to create a temperature of 400-500 degrees Celsius and a pressure of 50-300 kg / cm 2 . And we are waiting for the moment of transition to a liquid state. If a solvent is not used, then only 5-8% of the total mass of coal will become such. Then comes the turn of the catalysts. Suitable for coal: molybdenum, nickel, cobalt, tin, aluminum, iron, as well as their compounds. For gasification, you can use any type of raw material. Brown, stone - everything will do. Although its quality affects the conversion efficiency. Previously, the number of carbons was indicated and the figure was 8%. This is not entirely true. Depending on the brand and quality, the value can range from 4% to 8%. And for the minimum suitability of the subsequent processing and gasoline isolation, it is necessary to achieve a value of 11% (better than 15%). Initially, not the fact that everything will turn out. Especially if you were walking lessons in physics and chemistry. Nevertheless, synthetic coal gasoline can be successfully made and used.

Work with biogas

This is a rather unusual and extravagant approach, however it works. Its charm also lies in the fact that it has wider application as a fuel than just synthetic gasoline. True, it takes up a lot of space. So, for example, one cubic meter of biogas is equivalent to 0.6 liters of gasoline. If you use it not in a compressed state, then even taking the truck to the eyeballs, you will not be able to drive more than a hundred or two kilometers. Therefore, how to synthesize the desired gasoline from it ? This is possible due to the fact that, in fact, it is methane with small impurities. That is practically what is needed. But synthesis is a problematic matter. After all, here something new and at the same time simple was not invented. That is, it is necessary to work on the creation of synthesis gas, and from it to ensure the formation of gasoline. This is done (according to the most common scheme) through methanol. Although you can work through dimethyl ether. If we talk about methanol, it is always necessary to remember that it is extremely dangerous. The situation is complicated by the fact that it has the smell of alcohol, and the boiling point is 65 degrees Celsius. In general, working with fuel synthesis is not a children's walk. Therefore, it will not be superfluous to learn chemistry and physics if this knowledge is not available. In short, synthetic gasoline is obtained through gas distillation and a condenser. This method is not fast, but if there is a good theoretical background, it is not complicated. But working without knowledge is not recommended. Indeed, pure methanol is the highest octane fuel, and therefore dangerous. And his engine of a conventional machine will not “digest” - it is not designed for this.

Conclusion

That’s how to get synthetic fuel. It should be noted that this is not a toy, but a flammable activity. Therefore, without proper theoretical preparation, one should not engage in such a thing. After all, this will be a direct violation of safety rules. And they, it should be remembered, are always written in blood.