Industrial reverse osmosis plants are characterized by a high degree of water purification and low operating costs. The main element of the working module is a block of membranes through which fluid is passed. The created overpressure contributes to the reverse osmosis process - the flow of “solvent” (pure water) through the membrane. Unlike traditional chemical desalination, this technology is more environmentally friendly, since it does not require the use of aggressive reagents.

Appointment

Industrial reverse osmosis plants are used to purify water from mineral salts with a view to its further use in industrial, commercial and domestic purposes. This technology is very promising, since it allows you to remove very small particles from the liquid - up to 0.0001 microns (calcium and magnesium salts that affect the hardness of water, sulfates, nitrates, dye molecules).

Water purification in this way finds application in areas such as:

- a decrease in the amount of salts in the waters extracted from local above-ground (springs, rivers, lakes) and underground sources;

- desalination of sea (brackish) water;

- preparation of solutions for technological processes;

- water treatment of boiler and boiler installations;

- finishing wastewater treatment in a closed water circuit;

- water disinfection for medical purposes;

- food industry - clarification, stabilization and concentration of juices, soft drinks and wines.

Most often, industrial reverse osmosis plants are part of two-stage treatment systems. At the first stage, the liquid undergoes mechanical filtration, with the help of which larger particles are removed.

The essence of technology

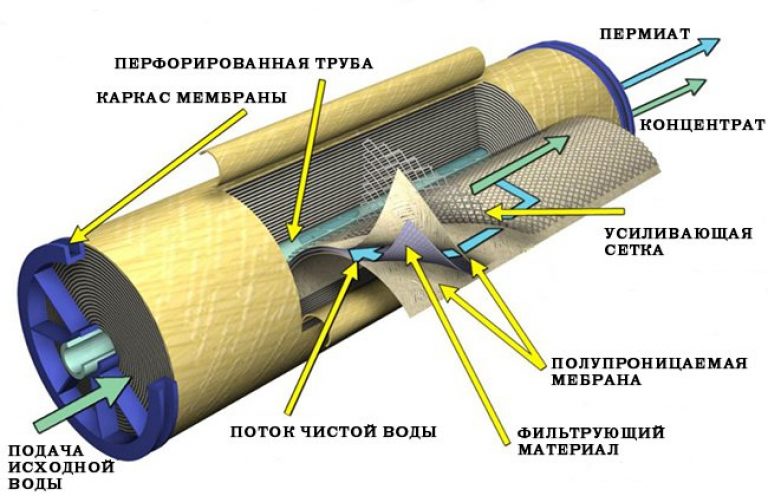

The principle of operation of the reverse osmosis system is that the liquid to be purified is passed through semipermeable membranes that completely or partially trap the molecules. With direct osmosis, water flows towards the solution. If you apply pressure in the first composition above the equilibrium (osmotic) value, then the water will move in the opposite direction. This ensures the selectivity of cleaning.

The required pressure level in the installation of a reverse osmosis filter depends on the concentration of salts (the higher it is, the higher the pressure). So, with a salinity of 20-30 g / l, it is 5-10 MPa. Cleaning equipment can use its own pressure of the industrial water supply system or increased pressure of the medium (use of pumps). The degree of purity of water is affected by the appearance of the membrane. When it becomes clogged, the system loses its effectiveness, therefore, it is necessary to carry out maintenance of this unit on time.

Equipment

The main components of industrial reverse osmosis plants are:

- base (stand);

- fine pre-filter (water treatment equipment);

- membrane blocks (their number is determined based on the performance of one block and the entire installation as a whole);

- high pressure pumps to provide the required differential pressure;

- piping with instrumentation and shutoff valves;

- washing unit for membrane cleaning;

- electric control cabinet and controllers.

Modern plants have a modular design, which allows final assembly at the installation site with selected characteristics that can be changed if necessary. The main unit is pressure housings with reverse osmosis membranes. Additionally, the installation of a reverse osmosis system can be equipped with the following types of equipment:

- water treatment system before osmotic treatment;

- capacity of pure or initial liquid;

- dispatch system.

The equipment may also include a system for inhibiting the deposition of salts (carbonates, sulfates and phosphates) on the membranes, which includes a metering pump for supplying the reagent, level sensors, valves and tubes. Installation of the pump in reverse osmosis is carried out separately. It is mounted on the tank with the reagent using the bracket, after which the reagent intake line and the level sensor in the tank are mounted. This process equipment allows you to extend the life of the membranes and reduce maintenance costs. An antiscalant (precipitation inhibitor) is added to water at a concentration of 2-5 mg / L.

Recommended Schemes

There are several layout options for industrial reverse osmosis plants, which are selected depending on the properties of the source water:

- Treatment of mineralized water coming from the well: coarse filter (CSF) - reverse osmosis unit (UOO).

- Water purification with a high content of iron, suspensions, high color: FGO - mechanical filling filters (through a layer of filtering load) - sorption filters - UOO.

- Water treatment with high salinity: FGO - ultrafiltration (water softening) - sorption filters - UOO.

Main characteristics

Settings differ in several main parameters:

- The purity of the flow passing through the membrane (80-99.8%).

- The pore size of the osmotic membrane (for the removal of heavy organic particles does not require the installation of membranes with particularly fine cleaning).

- Performance.

Types of Membrane Modules

The location and type distinguish the following main types of membranes:

- Tubular. The membrane is located on the inner cylindrical surface of the pipe, the stream of purified water exits through the side openings, and suspended particles are deposited down. The diameter of the tubes is most often in the range of 4-25 mm; they are placed in the housing in parallel or in series. The advantages of this scheme are its high flow velocity (up to 6 m / s), the absence of the need for preliminary fine filtration, and easy maintenance. The disadvantages include large dimensions and high processing costs.

- Fiber. Hollow fibers with a diameter of 0.6-2 mm are used. Water can flow both inside and outside. In some models, the fibers are fixed using a fabric mesh. Such membrane modules withstand external and internal pressure and can be regularly flushed with a backflow. Fiber systems are mainly used for ultrafiltration, since the holes are clogged with large particles.

- Lamellar. The membranes are fixed in the holder plate, and the module itself is a cassette with a set of rectangular frames. They are easy to install and clean, but the winding and complex configuration of the unit leads to a drop in pressure and reduces the reliability of the equipment.

- Spiral. Membranes and receivers of purified water (permeate) are wrapped in several layers around a central collector tube. Such modules are the most compact in comparison with other types, but are very sensitive to contamination.

Flat membranes are most often made from cellulose acetate or polyamide films.

Operating principle

The principle of operation of an industrial reverse osmosis plant is as follows:

- Preliminary cleaning in prefilters.

- The water is supplied by a high pressure pump to the membrane module, where it is divided into 2 streams - purified liquid and concentrate with high salinity.

- The output of purified water from the reverse osmosis unit, measurement of its flow rate, collection in containers.

- Discharge of concentrate into the sewer or its direction to the pump inlet (repeated recycling of the treatment).

With an unacceptable increase in backpressure, a relay is activated, which disconnects the installation. The same thing happens when filling the collection tank for purified water (level switch). Membrane flushing starts automatically.

Water preparation

Membrane technology for reverse osmosis involves the almost complete absence of mechanical impurities in the initial liquid. Industrial water treatment in this case is ineffective, because when transporting water through pipelines, foreign particles get into it. Therefore, pre-filters at the entrance to the membrane unit must be included in the reverse osmosis system.

Such equipment is usually made in a universal design and consists of at least 3 types of filters: coarse and fine cleaning, as well as for the collection of organic substances (sorption filters). Additional options are ultrafiltration, deferrization and clarification system. Failure to use this unit leads to the fact that the working membranes are quickly clogged, reducing the effectiveness of the reverse osmosis process.

Installation and commissioning

According to the installation instructions, reverse osmosis should be mounted indoors. Such installations are not intended for outdoor use.

Installation work is carried out in the following order:

- reagent system installation;

- connection of pipelines for supplying source water and receiving purified;

- programming the controller (setting the maximum permissible value of electrical conductivity, water temperature, duration of washing membranes before the working cycle, the time interval between cleaning them and other parameters);

- manual operation check (opening of the source water supply, the outlet valves of the purified liquid and concentrate, switching on the high pressure pump)

- putting the installation into automatic mode.