Now there are a huge number of technologies that allow you to quickly and reliably connect electrical wires and cables. Each of the methods has both pros and cons. Wires and cables are connected by welding or soldering. You can use twisting or fasten the conductors with terminal blocks, PPE. All of these methods are good and effective. But when you need to get a really high-quality connection, pressure testing of the occasions will help.

The result of this method is good contact, protected from oxidative processes and a particularly strong compound. The only negative is the inseparability. Disconnecting two cables will not work. You only have to cut it. Pressure testing of wires is carried out using special tips - sleeves. They can be purchased at any hardware store or market. The cost of these elements is about $ 1 per unit.

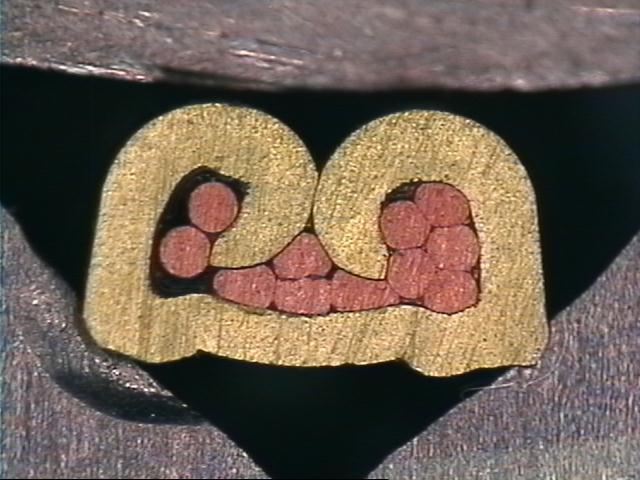

Cores are inserted into them. And the sleeve itself is then deformed with the help of a hand press, due to which a reliable electrical connection is created.

Why is crimping reliable?

Connection of wires by crimping is the most robust way to connect. No existing mounting option can provide such reliability. In order to obtain a high-quality connection, a sufficient contact area and strength should be provided. The twist of two conductors, popular among home masters, does not give either one or the other. When twisted, the conductors are often oxidized (even in the presence of electrical tape). And this does not affect the electrical contact very well. The use of insulating clamps or PPE can improve some strength characteristics for simple twisting.

However, there is no absolute guarantee of the reliability of such a connection here either. The terminal blocks are an ideal solution, but in the case of high current strength they do not fit. Good contact can be broken with soldering. Here both strength and excellent contact. But there are downsides to such a connection. The solder can heat up if a large current passes through the conductors. Also soldering wires is not always convenient and safe.

Perfect contact can be achieved by welding. However, the tools for creating such a connection are quite expensive and not accessible to everyone. Also, working with these devices requires certain skills. Crimping the wires allows you to get the perfect electrical contact, and the connection itself will be as reliable as possible in terms of strength. It is very difficult to break such fasteners.

Connection Features

The technology involves two crimping options. This is a method of local indentation and continuous compression. For work, copper or aluminum wires are used. The sleeve must also be made of these materials. There are still elements of copper-aluminum alloy.

Since aluminum cables are prone to the appearance of oxidizing films on them, the sleeve must first be cleaned and processed with special lubricants. Copper wires are also pre-processed. The use of lubricants in the process reduces the risk of possible core damage. The friction force also decreases markedly. Crimping is carried out with a manual or hydraulic tool. In the latter case, with a curly press. It is usually used in large industries.

How it works? The two ends of the cable are crimped until they take a round shape. Next, the core is inserted into the sleeve until it stops. Can not be connected exactly butt. But in this case, the cross section of all cores does not exceed the sleeve. In the case of local squeezing, the contact directly depends on the depth of the pits. The latter can be measured with a caliper. If continuous compression is used, then the cross-sectional area is checked. Then, when the crimping of the wires is successful, it is necessary to treat the outer layer with electrical tape or locotissue. Next, the wire and cable are neatly laid in the junction box.

Essential tool

In order to connect the wires or cores of the cable in this way, you will need a special tool. These are mechanical press tongs. They allow you to quite tightly clamp the ends of the sleeve along its entire length.

The hand tool allows you to compress the tip, the cross section of which is less than 120 mm 2 . The larger sleeve is compressed using a hydraulic tool. If the task is to connect several cable cores of various sizes, then it is better to use a tool for crimping wires of a different type. Such pincers are equipped with interchangeable punches and dies for different sections.

Sleeves for wires for crimping and their varieties

To get the perfect connection, you must correctly select the sleeve or tip. In technical documents, sleeves for crimping wires have certain designations. So, there are the following types of tips:

- Copper.

- Aluminum.

- Combined.

- Insulated tips.

GM and GMF

Copper parts are used exclusively for working with copper cables and conductors. They are divided into two types - GM and GMF. The first are ordinary copper connecting sleeves. They are not protected in any way, have no protective coatings, are not pre-processed. Appearance resembles nothing more than an ordinary tube. GMD is also a copper sleeve, but it is tinned.

The surface of such a tip is covered with a layer of a special tin-bismuth alloy. This protective layer inhibits oxidative and corrosive processes. Copper oxidizes quickly, and a protective alloy avoids this. After connecting using GMD, copper wires do not enter into oxidation reactions. Some experts use tinned copper sleeves for crimping wires along with aluminum conductors. According to the masters, the tin layer does not give direct contact between the conductor and the copper sleeve. But this is not recommended. In the process of deformation, the integrity of the protective layer is violated, and corrosion is only a matter of time.

Aluminum sleeves

In technical documents they are designated as "GA" and are only suitable for working with aluminum. Do not use them for wires from other materials.

Combined sleeve

These are aluminum-copper tips. They are designated in the documents as GAM.

With their help, crimping copper wires end-to-end with aluminum is carried out. These devices are perfect in cases where you need to build up a new cable with old wiring. On the one hand, a copper core is inserted into the cartridge, on the other, an aluminum core. Two parts of such a cartridge are interconnected by friction welding.

GSI sleeves

These are insulated terminals for crimping wires. This sleeve is a conventional tin alloy tip. The top is coated with PVC insulation. With this device, multicore cables with copper components are perfectly connected to each other. ICG is good and easy to use - there is no need to remove insulation from it before the process.

Sizes of tips, design features

The minimum available cross sections for GMFs are 1.5 mm 2 . Further, the dimensions grow - 2, 4, 6, 10 mm 2 and higher. According to these values, it can be said that the cross-sections of the sleeves are equal to those of wires and cables. Deciphering the designation of the tips is quite simple. For example, GML-6 is a tinned copper tip. The cross section is 6 mm 2 . In the case of combined sleeves, two sizes are indicated in the marking - for aluminum wire and for copper. For example, GAM 16/10 - 16 for aluminum, and 10 - for copper.

According to the design, the sleeves can be through in the form of a hollow tube or with a partition. The second ones are used if the crimping of wires is carried out with end-to-end tips. These partitions are located in the middle of the sleeve. With their help, you can adjust the depth of entry of the cable. If it is necessary to increase it, then both ends will go into the tip to the same length.

Errors during crimping

Often, novice specialists in working with an electrician can make mistakes. Especially they are made by home craftsmen in the process of repairing a house or apartment. Consider the most common of them that are allowed during the connection by crimping. The cross section of the sleeve is smaller than the wire. When connecting, you should never try to reduce the cable and adjust it to the size of the tip.

This can lead to increased electrical resistance and reduced throughput. In places of such compounds, the vein will become very hot, and over time it will simply collapse. The second popular mistake is a sleeve, the diameter of which is larger than necessary. In this case, it will not be possible to obtain the necessary mechanical strength of the joint. Even bending the core several times, you still can’t get a good connection.

Sleeve cutting

When crimping copper wires or any other in the conditions of a shortage of sleeves, many try to cut the tip into several parts. This is due to saving money. But such an action will only lead to increased resistance and heating. Also, the wire will be badly crimped. Connection is carried out only with the tool intended for this. Do not try to perform the task of crimping and crimping with hammers, pliers or other other tool. The element will not take the desired shape and will not fix the wire. This can damage the sleeve and the cable.

Summary

Crimping is a reliable way to connect two wires or cores and get a good contact. But it is necessary to use only the devices intended for this. As a result, you get a quality one-piece compound that will not oxidize.