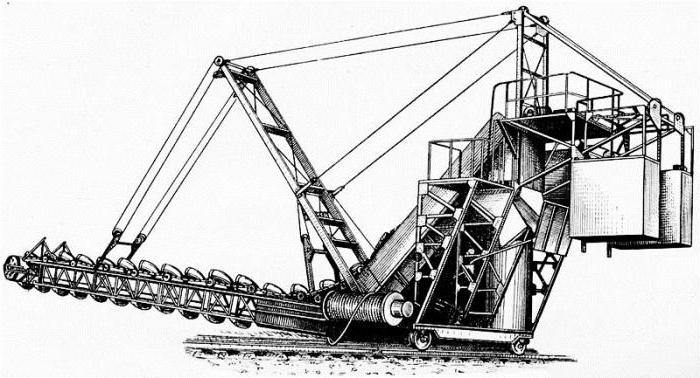

Bucket-wheel excavators are used in the process of mining minerals (gravel, clay, etc.) for rock removal. They are also used for profiling slopes of railway excavations and canals, as well as for handling loose materials and waste rock. This technique can process soils up to category 4, which do not contain large stones (inclusions). A bucket excavator works smoothly if the diameter of the inclusions does not exceed a fifth of the width of the bucket.

It is noteworthy that the surface of the face when using this technique is smooth and does not need manual cleaning. In this article, we learn more about what a bucket excavator is.

Specifics of work

As a rule, bucket-wheel excavators are used in places where there is a large amount of work of the same type, concentrated on one site. The reason for this is simple - the large dimensions of the equipment. Transporting it from place to place for small tasks will be expensive and time consuming, which means it is impractical. For small jobs involving regular moving, there are small models of pneumatic or automobile excavators.

Types of bucket machines

The technique is classified according to the following criteria:

- In the direction of movement during operation. It can be excavators of longitudinal, cross digging or rotary models.

- By type (design) of working equipment. There are chain excavators and bucket wheels.

- By the method of supplying equipment to the face. Cutting the rock can be vertical radial, horizontal radial, or vertical parallel.

Based on these signs, it can be concluded that there are several types of excavators. Let's consider each of them separately.

Cross Digging Machines

This is a bucket chain excavator, which can be tracked or rail. It works by parallel or radial cutting. The chain can be directional (used in homogeneous soils for mining or planning large channels and excavations) or freely sagging (used in soils with inclusions). There are also excavators, the caterpillar travel of which can vary depending on the working conditions. They are used for digging and cleaning the channels of drainage and irrigation systems.

Digging technique

This is a trencher bucket excavator. It happens on a caterpillar, wheel-caterpillar, pneumowheel or road. In turn, longitudinal digging models are divided into those that work with the ring chain, and those whose working body is a bucket wheel (rotor). The former are used for digging trenches with a width of not more than 1.1 m and a depth of up to 3.5 m. The second can dig deeper holes - 1.6-1.8 m.

Rotary Full Rotary

As a rule, this type has a caterpillar track. But sometimes there is a rail. The device is equipped with a bucket wheel and electric drive. He can cut the rock by the radial method in horizontal and vertical planes. It is used for mining, which occur in the form of interlayers. It can be refractory clays and other materials. A bucket excavator (rotary) is also used in large construction and overburden works.

Benefits of bucket machines

Despite the fact that shovels are much more widespread, shovels have a number of undeniable advantages that allow them to maintain their market position. Let's analyze these features:

- Continuous excavation work. Meanwhile, in a single-bucket apparatus, the period of direct soil sampling is a maximum of 30% of the entire working time.

- If we compare the multi-bucket and single-bucket model with the same performance, we can see that the single-bucket machine is heavier and cumbersome.

- A bucket excavator consumes much less energy for excavating 1 cubic meter of rock than an apparatus of the same capacity, but with one bucket.

- When working in a construction career, a multi-bucket device provides the possibility of both uniform mixing of the rocks of the extracted material and their sorting.

- By developing soil, a bucket excavator processes bevels. As a result, the recess receives an almost perfect cross-sectional profile. A single-bucket machine develops a notch with ledges and leaves a shortfall in each of them.

Disadvantages of technology

However, there are parameters by which a single-bucket excavator clearly wins. Perhaps it is because of them that he still leads the market. A bucket excavator has such weaknesses:

- This machine is a real gourmet, which is able to develop only homogeneous soil not higher than grade 4 or with small inclusions up to grade 3. A single bucket excavator can work with any class and type of soil, including rock formations, without any problems.

- A machine with one bucket is not picky about weather conditions, which cannot be said about the multi-bucket option.

For clarity, we will analyze a couple by the example of a bucket excavator.

EM-251

This is a domestic device, which consists of:

- Running and power equipment, as well as mechanisms mounted on a fixed frame of the conveyor belt, which is designed to dump the soil to the side or in the back of the vehicle.

- Working equipment (chain with buckets) mounted on a boom frame.

A multi-support caterpillar acts as a running equipment. An internal combustion engine transmits rotation to the drive gears via a chain drive. Caterpillars have frames connected by means of half shafts and a balancing device to the main frame. It turns out that the main frame rests on the tracked at three points. This allows you to achieve a good cross of the excavator.

When the bucket chain and the excavator itself move, a vertical trench forms. The soil, taken by buckets, through the hopper falls onto the dump conveyor. He, in turn, throws him aside.

Excavators multi-bucket trench chain models EM-251 can change the position of the boom relative to the frame. It rolls along the guides, which allows you to change the degree of its deepening, and therefore the depth of the trench. When transporting the machine, the boom is in the up position. The machine is controlled using a special remote control, which is located in the operator's cab on the right, near the gearshift lever. This allows the driver to simultaneously monitor the movement of the apparatus and the operation of digging mechanisms.

EM-182

We will analyze another shovel excavator. Em-281 - so sometimes this model is mistakenly called. It consists of:

- Undercarriage with single rib wheels. A removable frame is installed on it, carrying the hopper, the turrus shaft, the counterweight truss, the cabin, the upper part of the bucket frame, and, of course, the engine with the transmission.

- The lower part of the bucket frame, which has two planning links carrying a chain with buckets.

- Cuts, which supports a channel system and block suspension.

- Electrical equipment and lighting devices.

The excavator is controlled by three levers located in the operator's cab. The first is responsible for turning on the bucket chain. The second - for the course of the cart. Well, the third - for raising and lowering the boom. The latter is delayed in position due to the brake located on the worm shaft. The electric motor transmits the movement through the V-belts, the tension of which, as well as the angle of envelope of the pulley, is determined by the position of the tensioner. The main shaft transmits rotation through the chain drive to the gearbox. The soil cut by the buckets is transferred to the hopper, and then it enters the trolleys transporting it to its destination.

Thanks to the lifting winch, the multi-bucket excavator, the photo of which is shown above, can be used for both upper and lower parallel scooping, during which both ends of the bucket frame synchronously rise and fall. Thus, the bucket frame moves parallel to itself. In this case, the buckets remove a layer of the same thickness at any height of the bottom. In order to carry out a fan cut, which implies the movement of only one end of the frame, it is lowered accordingly.

Conclusion

Today we found out what are shovels and why they are not as common as shovels. It is worth noting that the limitations of machine performance imposed by the type of soil are very arbitrary and different for different types of excavators. A continuous improvement of bucket machines and the introduction of new design solutions suggests that in the near future all the shortcomings will be eliminated

By the way, continuous digging machines are also conventionally referred to as bucket excavators, despite the fact that instead of buckets, the working body in them is milling cutters or scrapers.