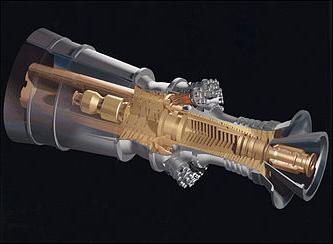

A gas turbine is an engine in which, during continuous operation, the main organ of the device (rotor) converts the internal energy of the gas (in other cases, steam or water) into a mechanical plan. In this case, the jet of the working substance acts on the blades fixed around the circumference of the rotor, causing them to move. In the direction of the gas flow, the turbines are divided into axial (gas moves parallel to the axis of the turbine) or radial (perpendicular movement relative to the same axis). There are both single and multi-stage mechanisms.

A gas turbine can act on blades in two ways. Firstly, it is an active process when gas is supplied to the working area at high speeds. At the same time, the gas flow tends to move in a straight line, and the curved blade part standing in its path deflects it, turning itself. Secondly, it is a reactive type process when the gas feed rate is low, but high pressures are used. There are almost no reactive engines in their pure form, since centrifugal force is present in their turbines , which acts on the blades together with the reaction force.

Where is a gas turbine used today? The principle of operation of the device allows it to be used for drives of electric current generators, compressors, etc. A widespread use of turbines of this type in transport (marine gas turbine plants). Compared to steam counterparts, they have a relatively small weight and dimensions; they do not need to equip a boiler room, condensing unit.

The gas turbine is quickly enough ready to work after start-up, develops full power in about 10 minutes, is easy to maintain, requires a small amount of water for cooling. Unlike internal combustion engines, it does not have inertial effects from the crank mechanism. A gas turbine installation is one and a half times shorter than diesel engines and more than two times lighter. The devices have the ability to run on low-quality fuel. The above qualities make it possible to consider engines of such a plan of particular interest to hovercraft and hydrofoils.

A gas turbine as the main component of the engine has a number of significant drawbacks. Among them, they note high noise, lower than that of diesel engines, economical, short term of operation at high temperatures (if the used gas medium has a temperature of about 1100 , then the turbine can be used for up to 750 hours on average).

The efficiency of a gas turbine depends on which system it is used in. For example, devices used in the energy sector with an initial gas temperature above 1300 degrees Celsius, with a compression ratio of air in the compressor of no more than 23 and at least 17, have a coefficient of about 38.5% during autonomous operations. Such turbines are not very widespread and are mainly used to block load peaks in electrical systems. Today, about 15 gas turbines with a capacity of up to 30 MW operate at a number of thermal power plants in Russia. In multi-stage plants, a much higher efficiency is achieved (about 0.93) due to the high efficiency of the structural elements.